Quaternary phosphonium salt antibacterial ultrafiltration membrane and preparation method thereof

A technology of ultrafiltration membranes and quaternary phosphonium salts, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve problems such as microbial adsorption, bacterial growth contamination, difficulty in automation, and degradation of membrane performance, and achieve water flux High, improved surface hydrophilicity, good anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (sample 1 comparative example):

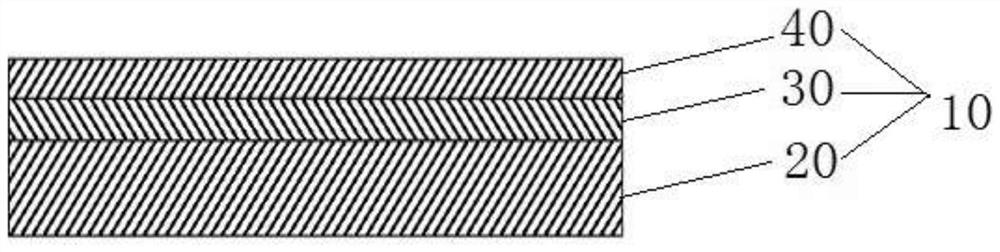

[0035]Mix PEG20000 containing 16wt% polysulfone membrane material with a mass concentration of 2.0wt% and organic solvent N,N-dimethylacetamide (DMAc), heat to 80°C and stir for 24 hours, cool to 25°C and let stand Degassing for 8 hours to obtain casting solution A; scrape coating casting solution A on a polyester non-woven mechanical support, and use 35°C pure water as a coagulation bath to prepare a flat ultrafiltration membrane separation by phase inversion method Functional layer 30.

Embodiment 2

[0036] Embodiment 2 (sample 2):

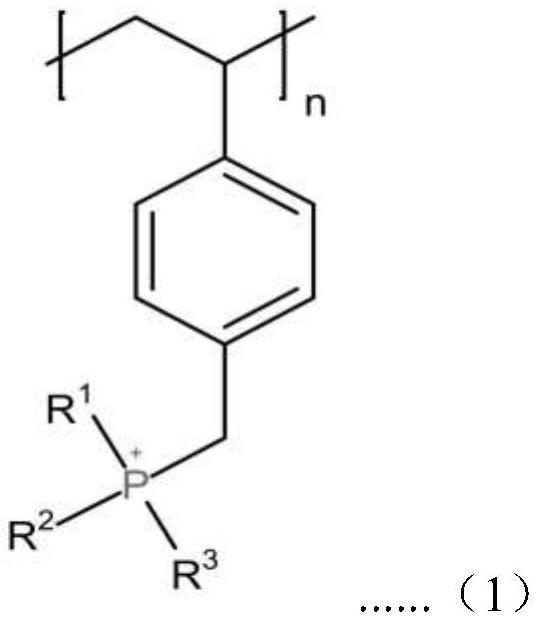

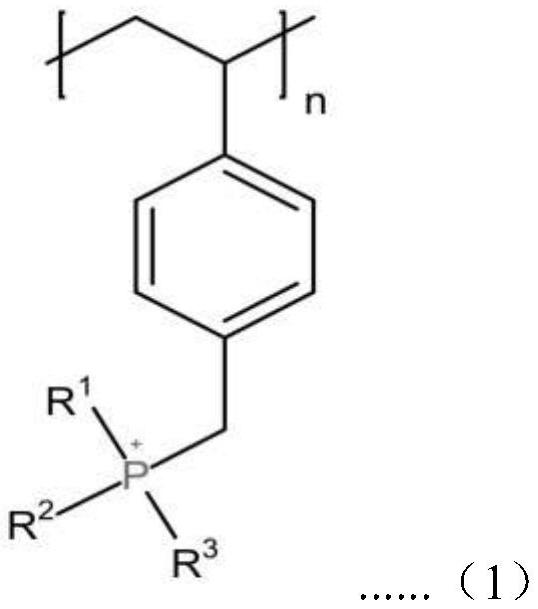

[0037] The surface of the separation function layer of sample 1 was immersed in an aqueous solution containing 0.5% by weight of polymer 4 for 5 minutes; then, the separation function layer was air-dried for 30 seconds, and further kept in a hot air drier at 120° C. for 2 minutes, thereby A polymer layer was formed on the separation functional layer; in this way, the separation membrane of Sample 1 was obtained; Polymer 4 was a polymer represented by formula (2).

[0038]

Embodiment 3

[0039] Embodiment 3 (sample 3):

[0040] Compared with Example 2, the difference is that the concentration of polymer 4 in the aqueous solution was changed to 0.03% by weight, and a separation membrane was obtained by the same method as sample 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com