Thin film and preparation method thereof

A thin film and metal thin film technology, which is applied in the field of thin film and its preparation, can solve the problem that the thickness of the shielding cover cannot meet the demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

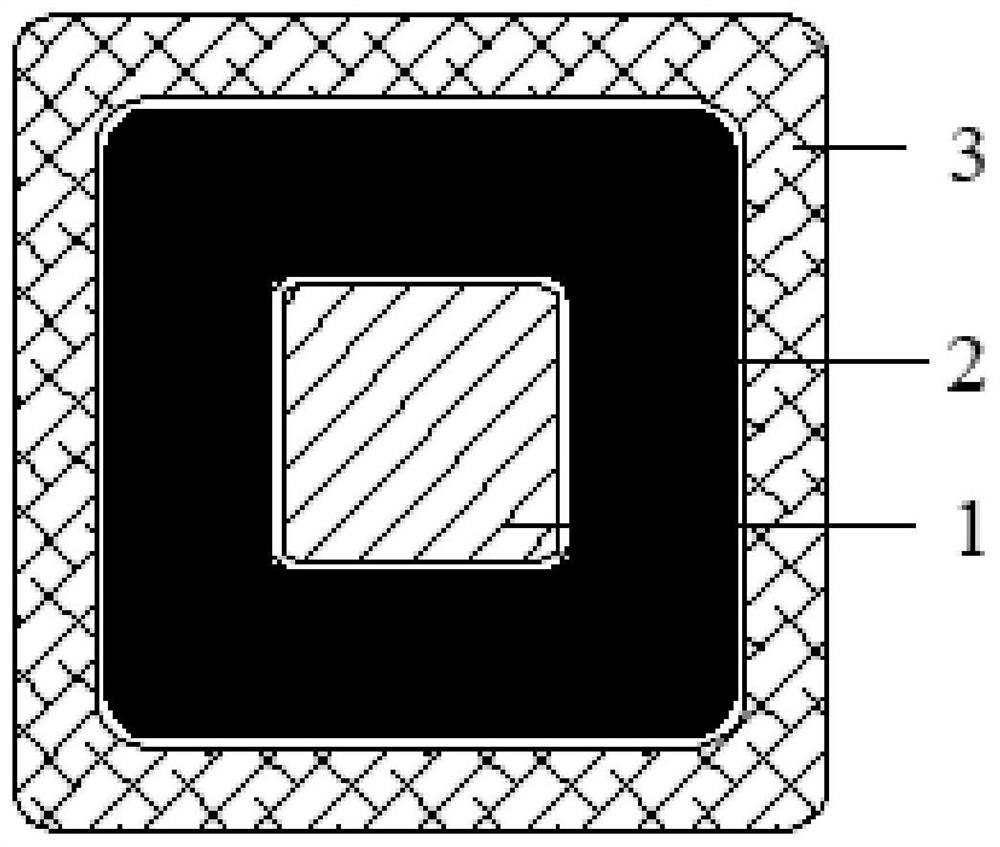

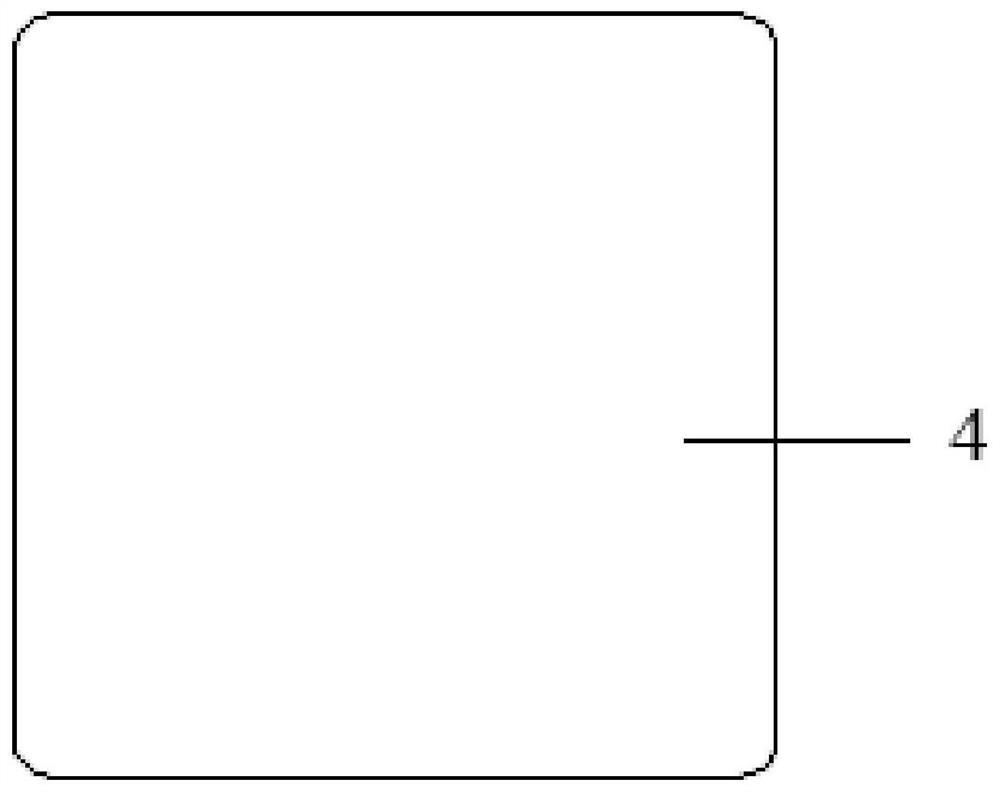

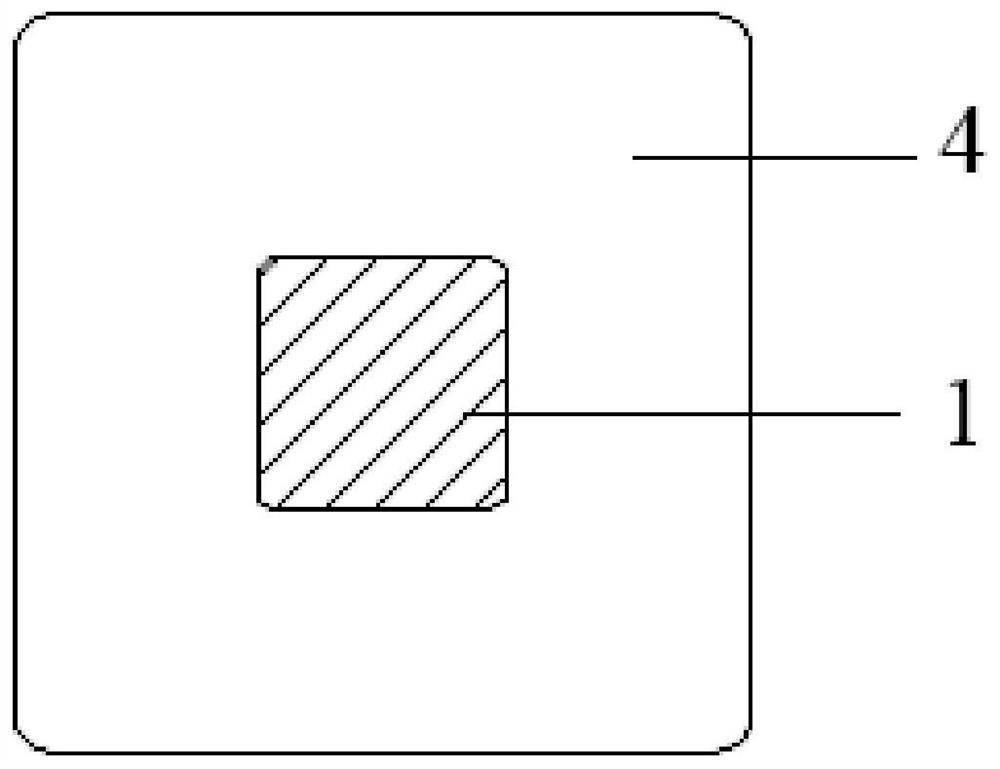

[0054] 1. Mix 5g of polyolefin and 5g of paraffin in a planetary mixer and mix evenly, then add 5μm aluminum powder and 1um aluminum powder in a weight ratio of 7:3 to a total of 80g, add xylene solvent to dilute, mix and stir for 15min, and then add evenly The joint agent was 0.4g, and after stirring for 15 minutes, a phase-change thermally conductive slurry was obtained. Position and coat the phase-change heat-conducting paste on the corresponding position of the copper foil 4, the heat-conducting paste is coated in a square of 15 mm, and the copper foil 4 is in a square of 30 mm to obtain a semi-finished product a. For details, refer to image 3 , shows a schematic structural view of a film semi-finished product a provided by an embodiment of the present application.

[0055] The formula of the phase change thermally conductive paste is: 5g of polyolefin, 5g of paraffin, 0.4g of coupling agent, 56g of aluminum powder with a particle size of 5um, 24g of aluminum powder with ...

Embodiment 2

[0060] 1. Mix 5g of polyolefin and 5g of paraffin in a planetary mixer and mix evenly, then add 5μm alumina powder and 1um alumina powder in a weight ratio of 7:3 to a total of 80g, add xylene solvent to dilute, mix and stir for 15min, and then Add 0.4 g of coupling agent and stir for 15 minutes to obtain a phase change thermally conductive slurry. Positionally coat the phase-change heat-conducting paste on the corresponding position of the copper foil 4, the heat-conducting paste is coated in a square of 15 mm, and the copper foil 4 is in a square of 30 mm to obtain a semi-finished product a.

[0061] The formula of the phase change thermally conductive slurry is: 5g of polyolefin, 5g of paraffin, 0.4g of coupling agent, 56g of alumina powder with a particle size of 5um, 24g of alumina powder with a particle size of 1um, and 9.6g of xylene.

[0062] 2. Die-cut the insulating tape 2 into a 26mm square, punch out a 15mm square in the center of the insulating tape 2, and paste i...

Embodiment 3

[0066] 1. Mix 5g of polyolefin and 5g of paraffin in a planetary mixer and mix evenly, then add 5μm aluminum powder and 1um aluminum powder in a weight ratio of 8:2, a total of 80g, add xylene solvent to dilute, mix and stir for 15min, and then add evenly The joint agent was 0.45g, and after stirring for 15 minutes, a phase-change thermally conductive slurry was obtained. Positionally coat the phase-change heat-conducting paste on the corresponding position of the copper foil 4, the heat-conducting paste is coated in a square of 15 mm, and the copper foil 4 is in a square of 30 mm to obtain a semi-finished product a.

[0067] The formula of the phase change thermally conductive paste is: 5g of polyolefin, 5g of paraffin, 0.45g of coupling agent, 72g of aluminum powder with a particle size of 5um, 8g of aluminum powder with a particle size of 1um, and 11g of xylene.

[0068] 2. Die-cut the insulating tape 2 into a 26mm square, punch out a 15mm square in the center of the insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com