Feed additive for preventing and treating animal constipation as well as preparation method and application thereof

A technology for feed additives and constipation, which is applied in the field of feed additives and its preparation for the prevention and treatment of animal constipation. It can solve the problems of affecting normal feed intake of sows, occupying stomach space, and being unsuitable for sows. It achieves no risk of mycotoxins, less Formulation space, mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

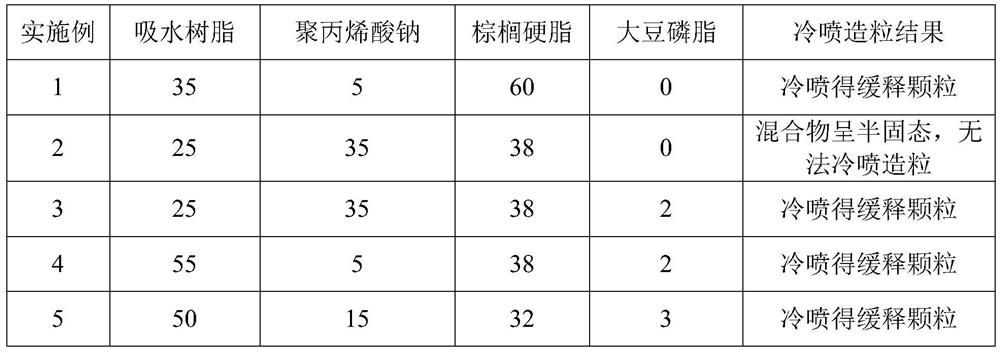

[0031] Embodiments 1-5 provide the preparation method of slow-release granules in feed addition, wherein the specific formula of the slow-release granules is shown in Table 1, and the preparation method of the slow-release granules is as follows:

[0032] (1) Take acrylic superabsorbent resin (Sumitomo SA60S) according to the proportioning ratio in Table 1, pulverize it to a particle size of less than or equal to 25 microns with an ultrafine pulverizer, and set aside;

[0033] (2) Take sodium polyacrylate according to the proportioning in Table 1, pulverize to a particle diameter of less than or equal to 25 microns with an ultrafine pulverizer, and set aside;

[0034] (3) Take hydrogenated palm stearin according to the proportioning in Table 1 and put it into the interlayer material tank, heat to melt, then add soybean lecithin;

[0035] (4) Add water-absorbent resin and sodium polyacrylate powder while stirring, and keep the material temperature at about 80°C;

[0036] (5) C...

Embodiment 6

[0040] The feed additive provided in this embodiment is prepared by the following method:

[0041] (1) Take 50kg of acrylic acid superabsorbent resin (Sumitomo SA60S), pulverize it to a particle size of less than or equal to 25 microns with an ultrafine pulverizer, and set aside;

[0042] (2) take by weighing 13kg sodium polyacrylate, pulverize to particle diameter less than or equal to 25 microns with ultrafine pulverizer, for subsequent use;

[0043] (3) Weighing 35kg of hydrogenated palm stearin and 2kg of soybean lecithin are put into the interlayer material tank, heated to melting;

[0044] (4) Add water-absorbent resin and sodium polyacrylate powder while stirring, and keep the material temperature at about 80°C;

[0045] (5) Carry out cold spray granulation with a cold spray granulation tower to obtain slow-release granules;

[0046] (6) Take 99 kg of sustained-release granules, add 0.5 kg of capsaicin and 0.5 kg of xanthanin, and mix to obtain a finished product.

Embodiment 7

[0048] The feed additive provided in this embodiment is prepared by the following method:

[0049] (1) Take by weighing 40kg acrylic type superabsorbent resin (Sumitomo SA60S), pulverize with a pulverizer, pass through a 100-mesh sieve, and set aside;

[0050] (2) Take 10kg sodium polyacrylate, pulverize with pulverizer, cross 100 mesh sieves, and set aside;

[0051] (3) Take by weighing 49kg of hydrogenated palm stearin and 1kg of glyceryl monostearate and put them into the interlayer material tank, and heat to melt;

[0052] (4) Add water-absorbent resin and sodium polyacrylate powder while stirring, and keep the material temperature at about 80°C;

[0053] (5) Carry out cold spray granulation with a cold spray granulation tower to obtain slow-release granules;

[0054] (6) Take 98 kg of slow-release granules, add 1.2 kg of capsaicin and 0.8 kg of xanthanin, and mix to obtain a finished feed additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com