Biomass activated carbon, preparation method and application thereof, and electrode

A technology of activated carbon and biomass, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., to achieve the effect of excellent rate performance, taking into account cost and environmental protection requirements, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

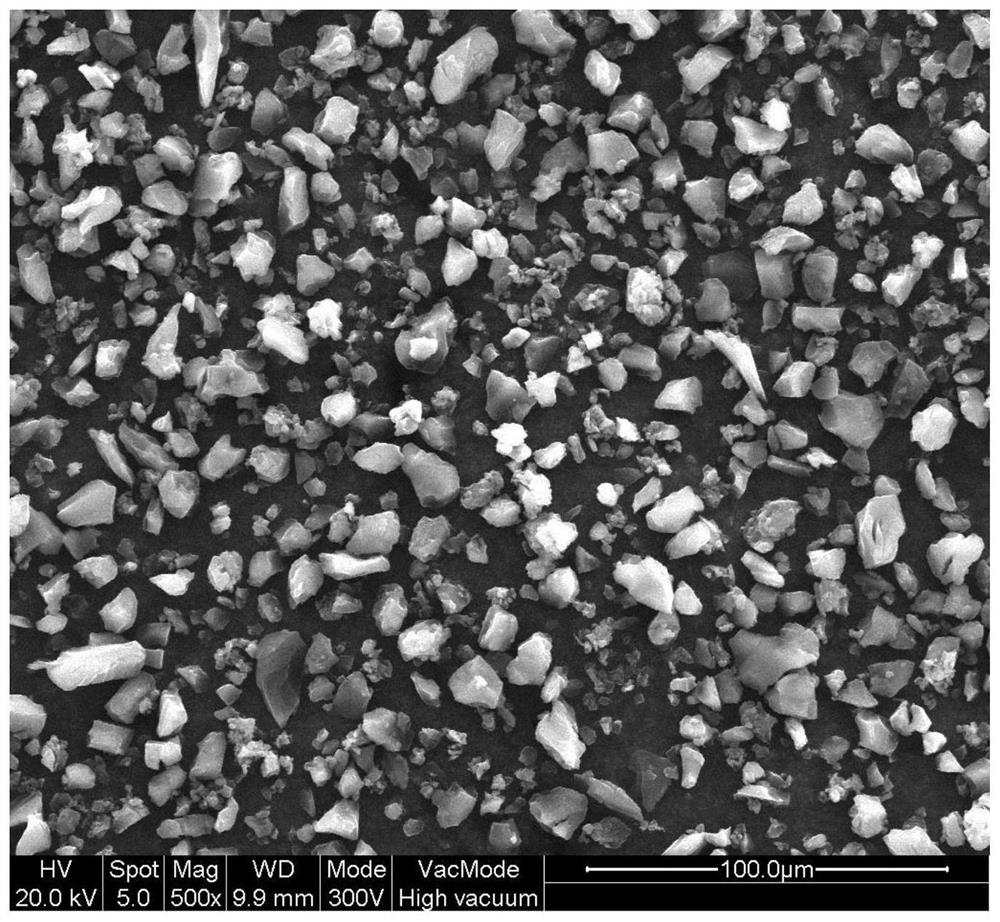

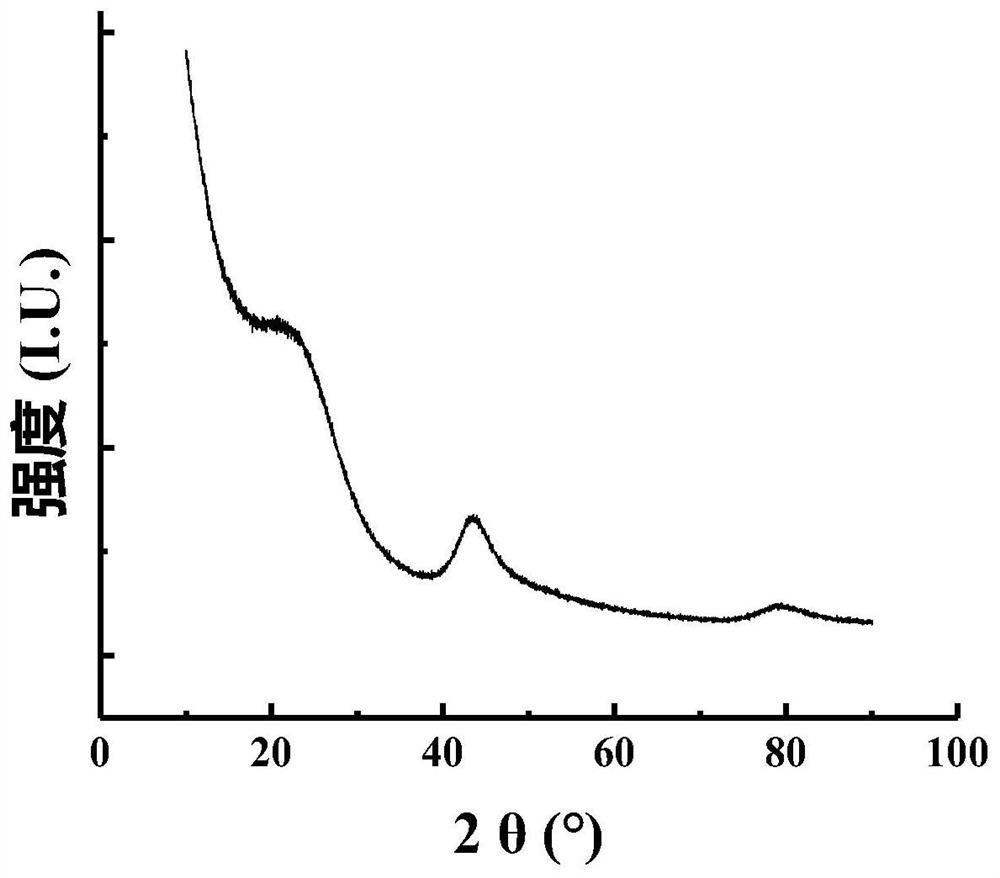

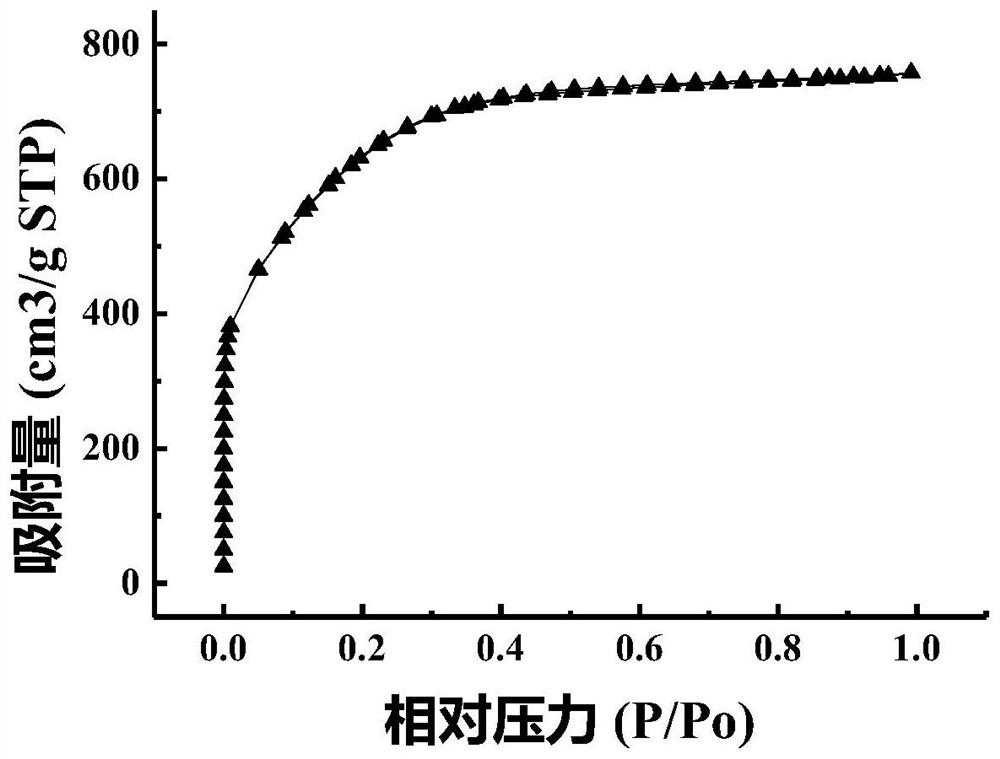

[0061] Preparation of coconut shell activated carbon:

[0062] (1) Crush coconut shell charcoal to a particle size of 14 μm, mix it with KOH powder at a mass ratio of 2:1 for 0.5 h, add it to the rotary furnace; heat up to 850 °C at a rate of 3 °C / min, and activate for 1 h (the first time Insulation), to obtain precursor A;

[0063] (2) At 850°C, within 1 hour, water vapor with a mass ratio of 1:1 to coconut shell carbon was introduced at a constant speed (second activation) to obtain precursor B;

[0064] (3) Precursor B was dispersed into hydrochloric acid with a mass fraction of 3% and a temperature of 80°C and then filtered for 1 h (the first pickling); washed with hot water at a temperature of 60°C and filtered (the first water wash ); with the mass fraction being respectively the mixed acid washing of 1% hydrochloric acid and 1% nitric acid and filtering (the second pickling); washing with hot water with a temperature of 50°C until the filtrate is neutral (the second wa...

Embodiment 2

[0067] Preparation of coconut shell activated carbon: Except that in step (2), the water vapor with the coconut shell carbon mass ratio of 2:1 is passed at a constant speed within 2h, other steps and conditions are consistent with Example 1.

Embodiment 3

[0069] Preparation of coconut shell activated carbon: except that coconut shell carbon and KOH powder are mixed according to the mass ratio of 1:1 in step (1), other steps and conditions are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com