Method for preparing NCA positive electrode material through one-step doping, coating and modifying

A positive electrode material and coating technology, which is applied in the field of preparation of NCA positive electrode materials, can solve the problems of long production time and high production cost, and achieve the effects of improving safety, simplifying stability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

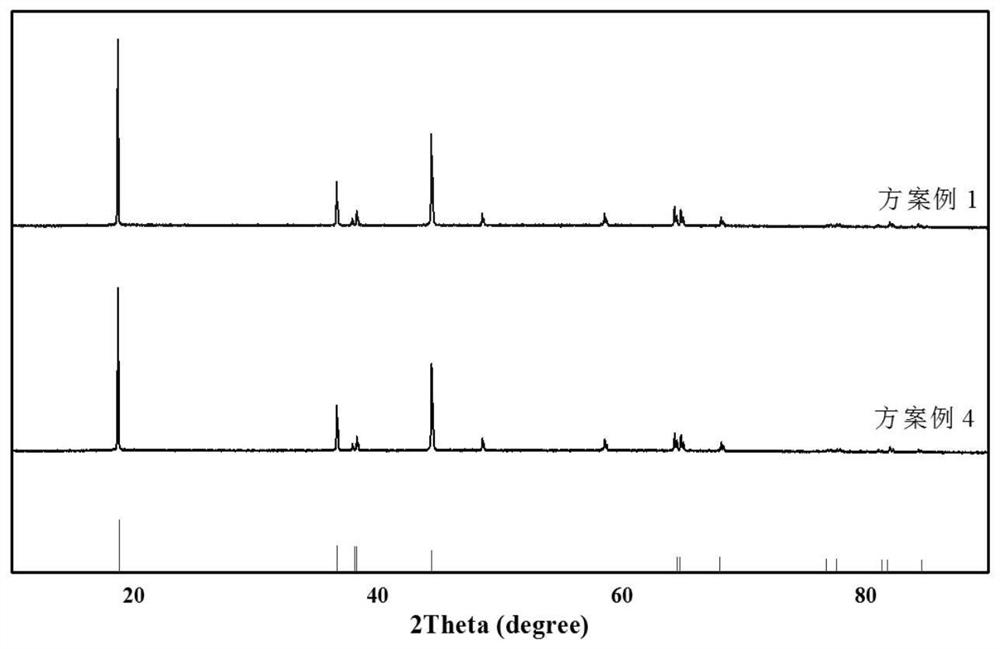

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a one-step doping coating modified NCA positive electrode material, including the following steps:

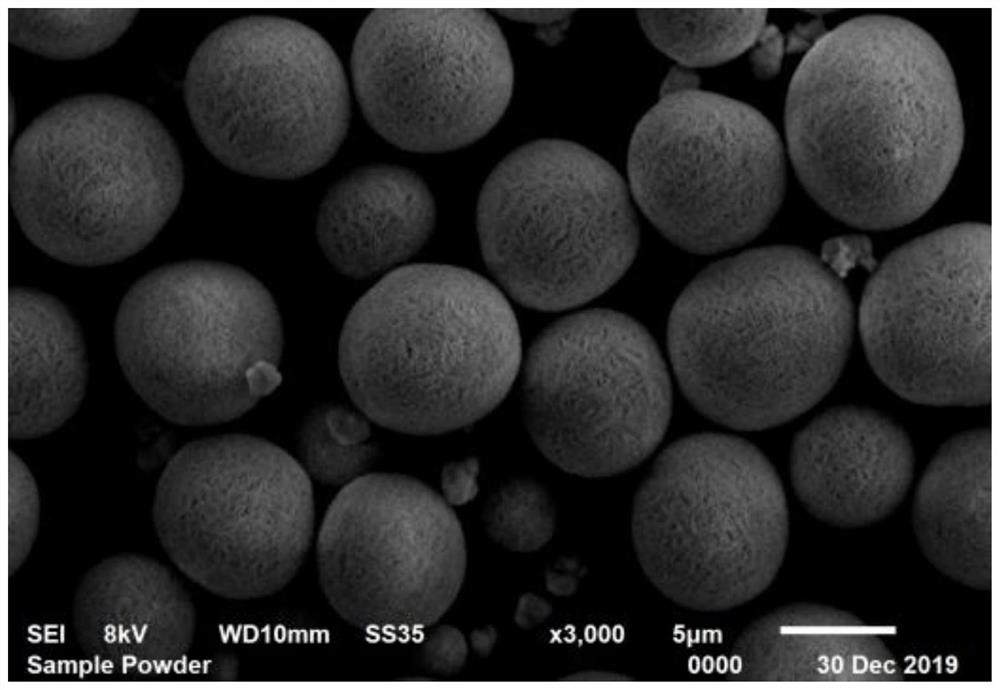

[0032] Taking nickel sulfate, cobalt sulfate, and sodium metaaluminate according to the metal cation molar ratio of 0.88:0.09:0.03 to prepare a mixed solution of nickel, cobalt, and sodium cations with a total concentration of 2mol / L, nickel sulfate, cobalt sulfate, and sodium metaaluminate, At a concentration of 0.2mol / L ammonia water, complex co-precipitation occurs at a volume ratio of 1:1. After aging, centrifugation, and drying, the average particle size D50: 8μm is obtained; the specific surface area BET: 10m 2 / g; bulk density: 1.1g / cm 3 , Tap density: 1.8g / cm 3 The precursor of Ni 0.88 co 0.09 Al 0.03 (OH) 2 .

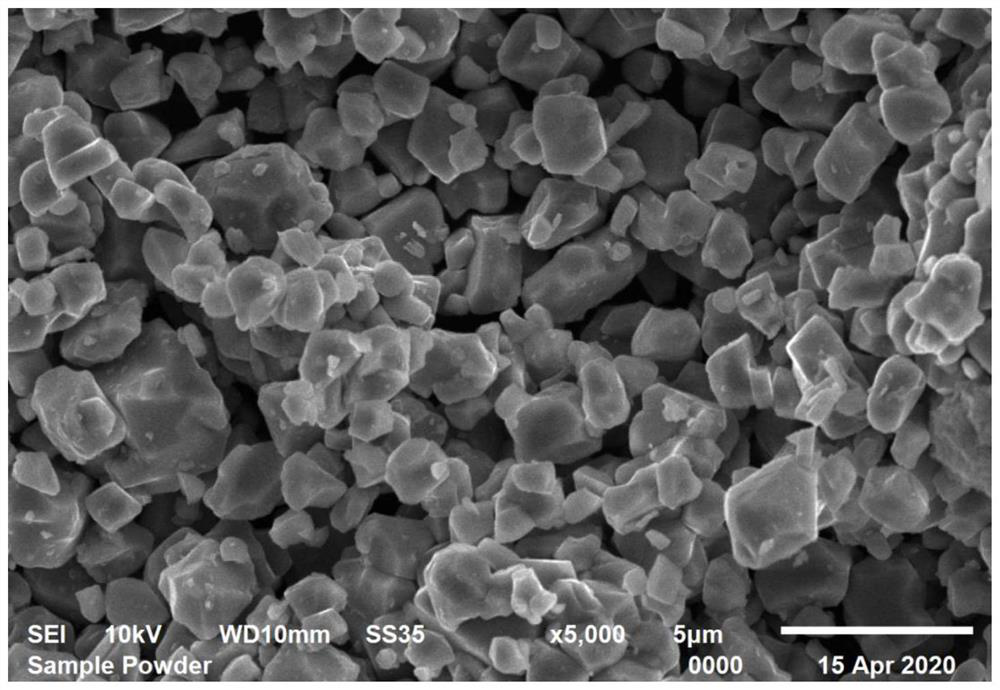

[0033] Add absolute ethanol to the precursor prepared above, and stir and mix lithium hydroxide, nano-zirconia, nano-titanium oxide and ammonium metatungstate in a constant temperature water bath cruci...

Embodiment 2

[0036] This embodiment provides a method for preparing a one-step doping coating modified NCA positive electrode material, including the following steps:

[0037] Taking nickel sulfate, cobalt sulfate, and sodium metaaluminate according to the metal cation molar ratio of 0.88:0.09:0.03 to prepare a mixed solution of nickel, cobalt, and sodium cations with a total concentration of 2mol / L, nickel sulfate, cobalt sulfate, and sodium metaaluminate, At a concentration of 0.3mol / L ammonia water, complex co-precipitation occurs at a volume ratio of 1:1. After aging, centrifugation, and drying, the average particle size D50: 7.8μm; specific surface area BET: 11m 2 / g; bulk density: 1.1g / cm 3 , Tap density: 1.8g / cm 3 The precursor of Ni 0.88 co 0.09 Al 0.03 (OH) 2 .

[0038] Add absolute ethanol to the precursor prepared above, and stir and mix lithium hydroxide, nano-zirconia, nano-titanium oxide and ammonium metatungstate in a constant temperature water bath crucible at 80°C, t...

Embodiment 3

[0041] This embodiment provides a method for preparing a one-step doping coating modified NCA positive electrode material, including the following steps:

[0042] Taking nickel sulfate, cobalt sulfate, and sodium metaaluminate according to the metal cation molar ratio of 0.88:0.09:0.03 to prepare a mixed solution of nickel, cobalt, and sodium cations with a total concentration of 2mol / L, nickel sulfate, cobalt sulfate, and sodium metaaluminate, At a concentration of 0.2mol / L ammonia water, complex co-precipitation occurs at a volume ratio of 1:1. After aging, centrifugation, and drying, the average particle size D50: 8.2μm; specific surface area BET: 9m 2 / g; bulk density: 1.2g / cm 3 , Tap density: 1.8g / cm 3 The precursor of Ni 0.88 co 0.09 al 0.03 (OH) 2 .

[0043] Add absolute ethanol to the precursor prepared above, and stir and mix lithium hydroxide, nano-zirconia, nano-titanium oxide and ammonium metatungstate in a constant temperature water bath crucible at 80°C, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com