Device and process for producing propylene glycol monomethyl ether acetate by reactive distillation coupled pervaporation

A technology of pervaporation and reactive distillation, which is applied in the field of producing propylene glycol monomethyl ether acetate, can solve the problems of low production efficiency, high energy consumption, and heavy equipment load, and achieve good effect, high conversion rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

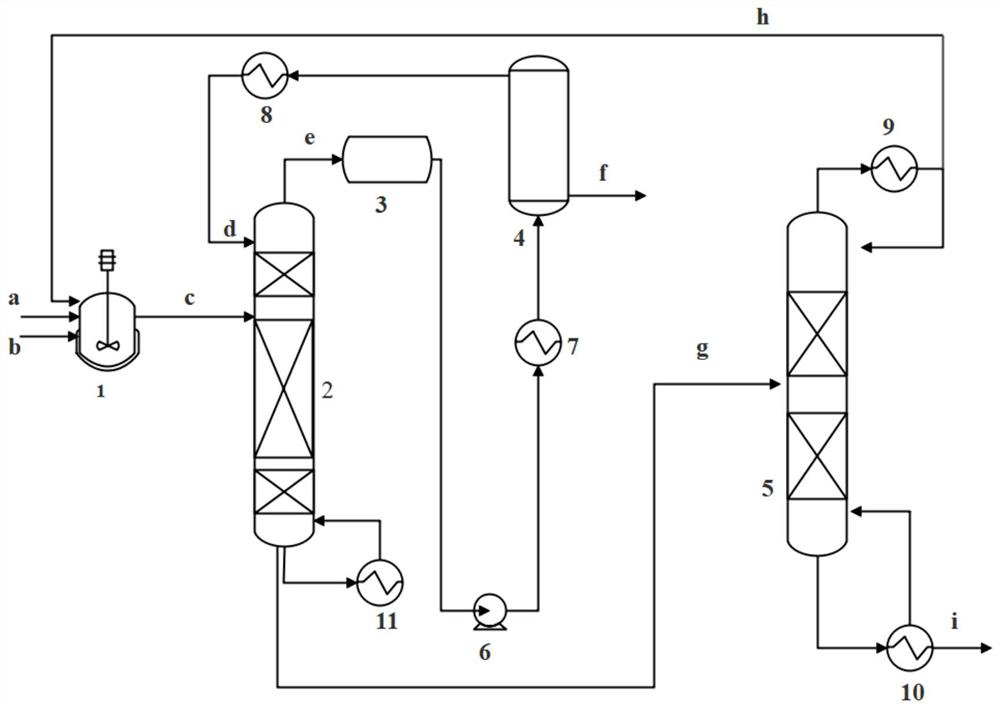

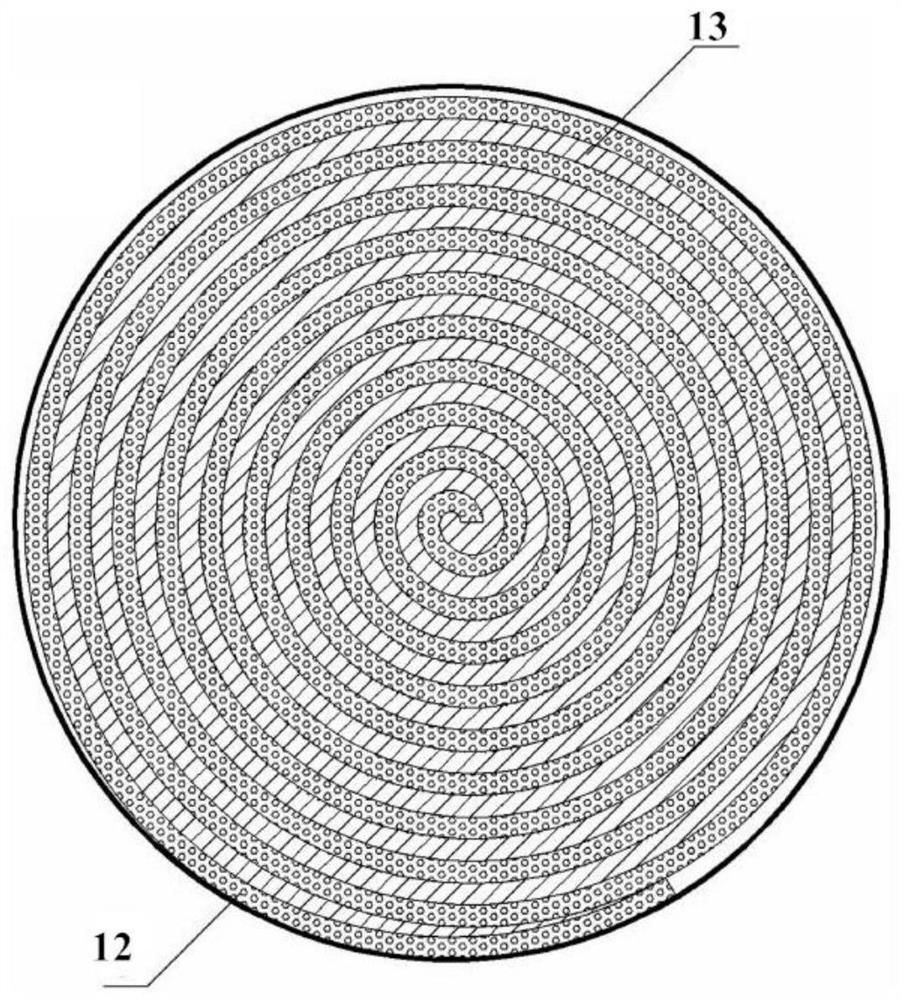

[0044] refer to Figure 1-2 A device for producing propylene glycol monomethyl ether acetate by reactive distillation coupled with pervaporation, said device comprising: a prereactor 1, a catalytic reactive distillation column 2, a pervaporation feed buffer tank 3, a pervaporation membrane module 4 and Product refining tower 5.

[0045] Prereactor 1 is provided with prereactor feed port and prereactor discharge port; the top of catalytic reaction rectification tower 2 is provided with rectification tower top discharge port and reflux material feed port, and the middle part is provided with rectification The tower feed port, the bottom of the tower is provided with the rectification tower bottom discharge port; the pervaporation feed buffer tank 3 is provided with the buffer tank feed port, toluene feed port and buffer tank discharge port; the pervaporation membrane module 4 is provided with There are gas-liquid mixing inlet, steam condensate outlet and organic steam outlet; t...

Embodiment 2

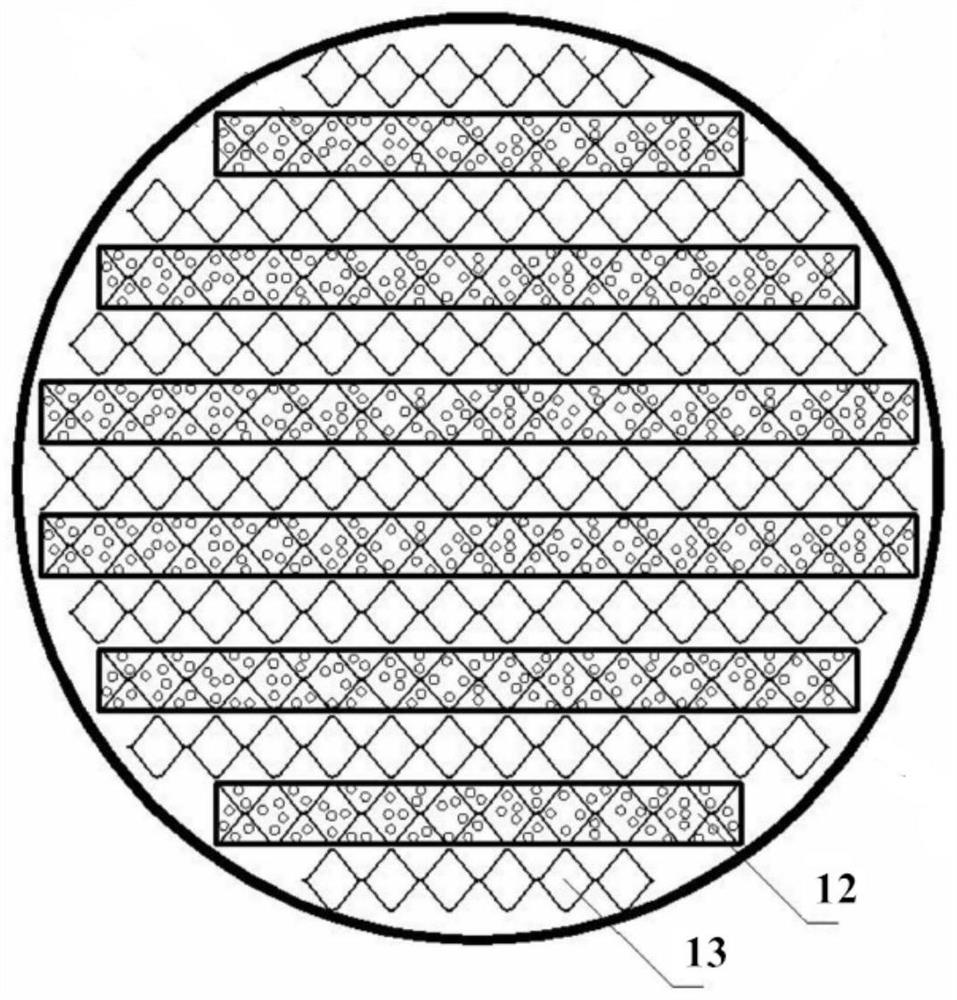

[0056] refer to figure 1 , 3 -4. A device for producing propylene glycol monomethyl ether acetate by reactive distillation coupled with pervaporation, said device comprising: a prereactor 1, a catalytic reactive distillation column 2, a pervaporation feed buffer tank 3, and a pervaporation membrane module 4 and product refining tower 5.

[0057] Prereactor 1 is provided with prereactor feed port and prereactor discharge port; the top of catalytic reaction rectification tower 2 is provided with rectification tower top discharge port and reflux material feed port, and the middle part is provided with rectification The tower feed port, the bottom of the tower is provided with the rectification tower bottom discharge port; the pervaporation feed buffer tank 3 is provided with the buffer tank feed port, toluene feed port and buffer tank discharge port; the pervaporation membrane module 4 is provided with There are gas-liquid mixing inlet, steam condensate outlet and organic steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com