Ultra-short carbon nanotube-graphene composite material and preparation method and application thereof

A carbon nanotube and composite material technology, applied in the direction of carbon nanotubes, multi-walled carbon nanotubes, graphene, etc., can solve the problem that the performance is difficult to maintain for a long time, the structural stability of composite materials is poor, and graphene and carbon nanotubes are easy to fall off and separate. and other issues to achieve the effect of enhancing the interaction force and maintaining long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

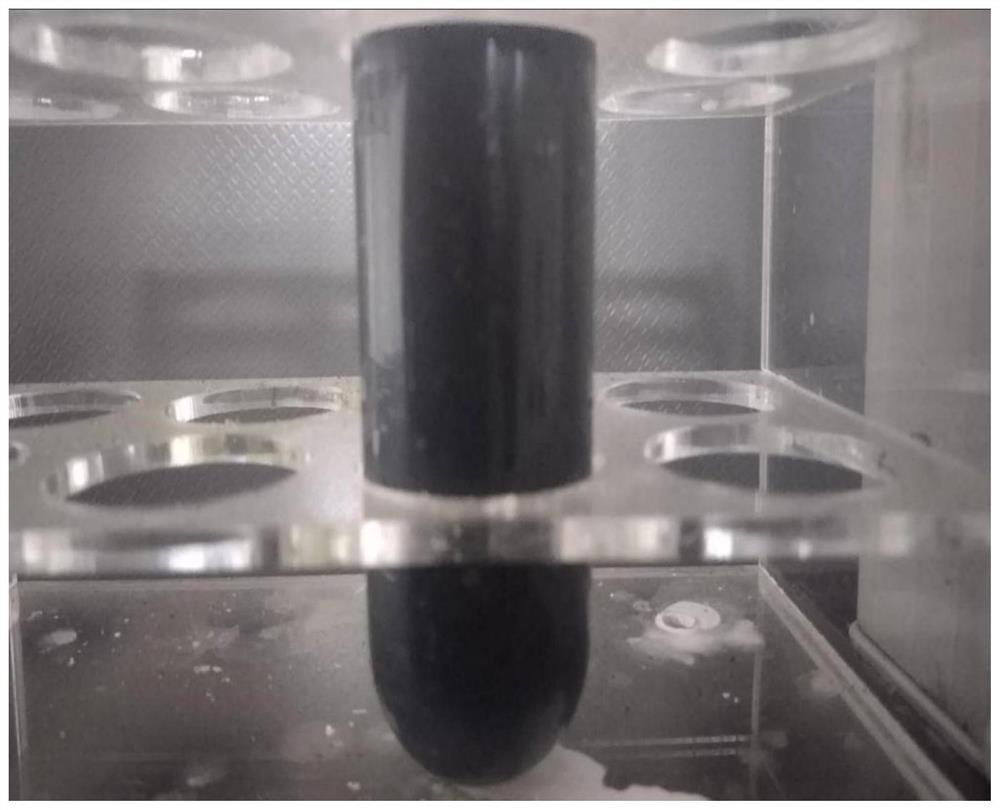

[0036] Step S1, measure 50mL of the ultra-short carbon nanotube dispersion prepared above and 25mL of the graphene oxide dispersion (volume ratio is 1:0.5), put them into two beakers respectively, and conduct them under ice bath conditions Ultrasonic dispersion for 60 minutes; then keep the ice bath condition ultrasonic, slowly drop the ultrashort carbon nanotube dispersion into the graphene oxide dispersion. material solution.

[0037] Step S2, adding a certain amount of NaOH to the ultrashort carbon nanotube-redox graphene composite solution in step S1 to adjust the pH value to 9, and then adding 1g NaBH 4 Stir to disperse evenly, and then conduct a controlled reduction reaction at 60°C for 1.5 hours under the protection of nitrogen. After the product is washed with deionized water for many times and filtered with PTFE, it is vacuum-dried at room temperature for 48 hours to obtain ultra-short carbon nanotubes- Graphene composites.

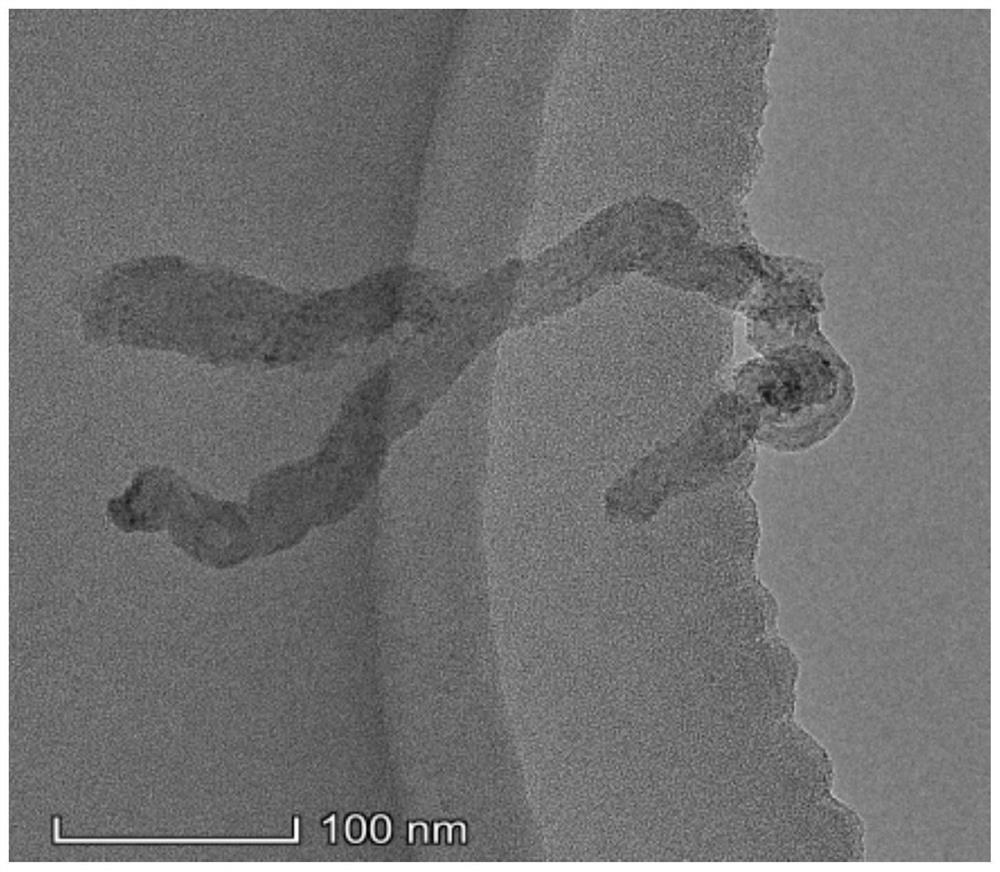

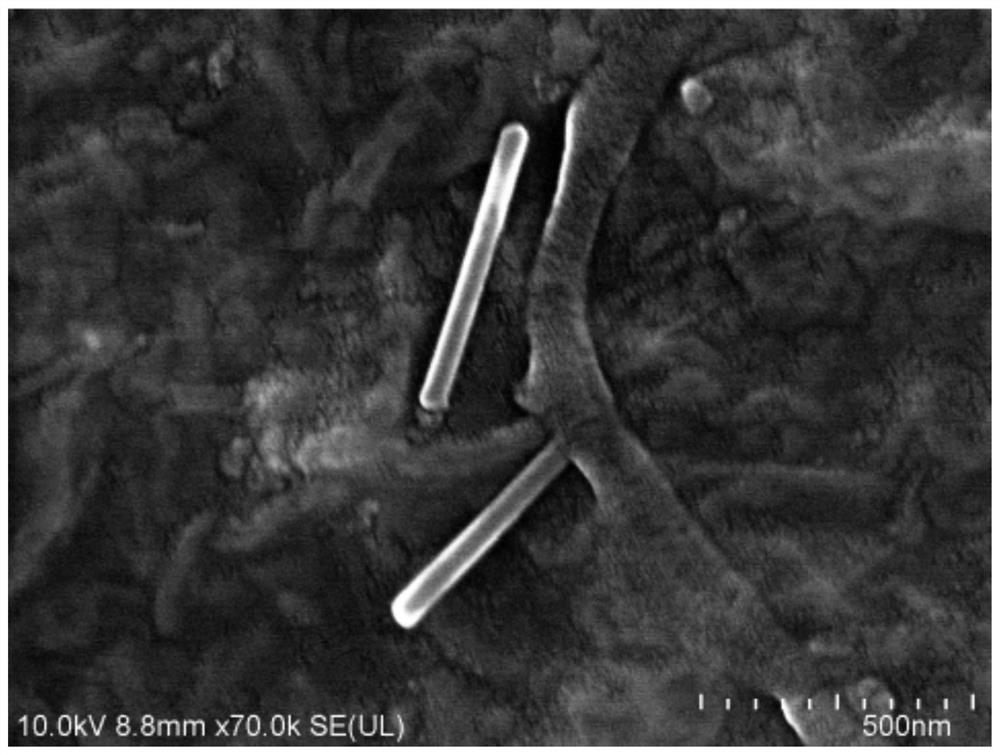

[0038] The ultrashort carbon nanotube-gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com