High-temperature device for preparing lithium ion battery negative electrode material and preparation method of material

A technology for lithium-ion batteries and high-temperature devices, which is applied to battery electrodes, negative electrodes, and methods for chemically changing substances by using atmospheric pressure. It can solve problems such as poor batch stability, excessively large particles, and uneven material quality. , to achieve batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

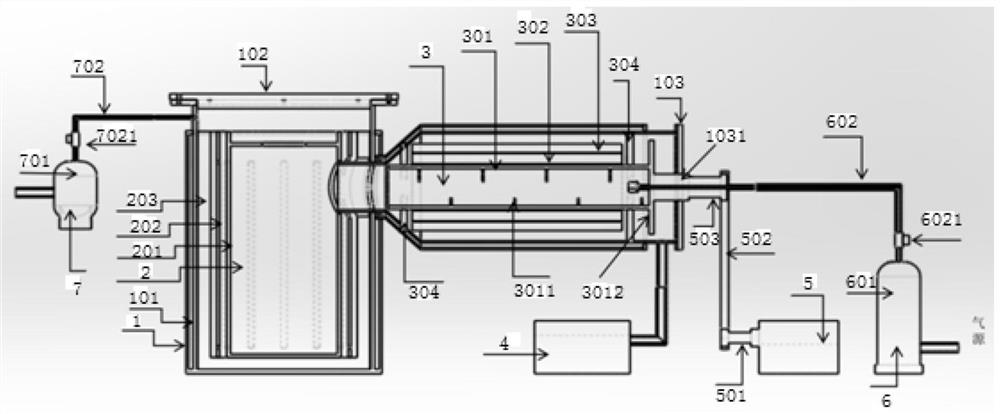

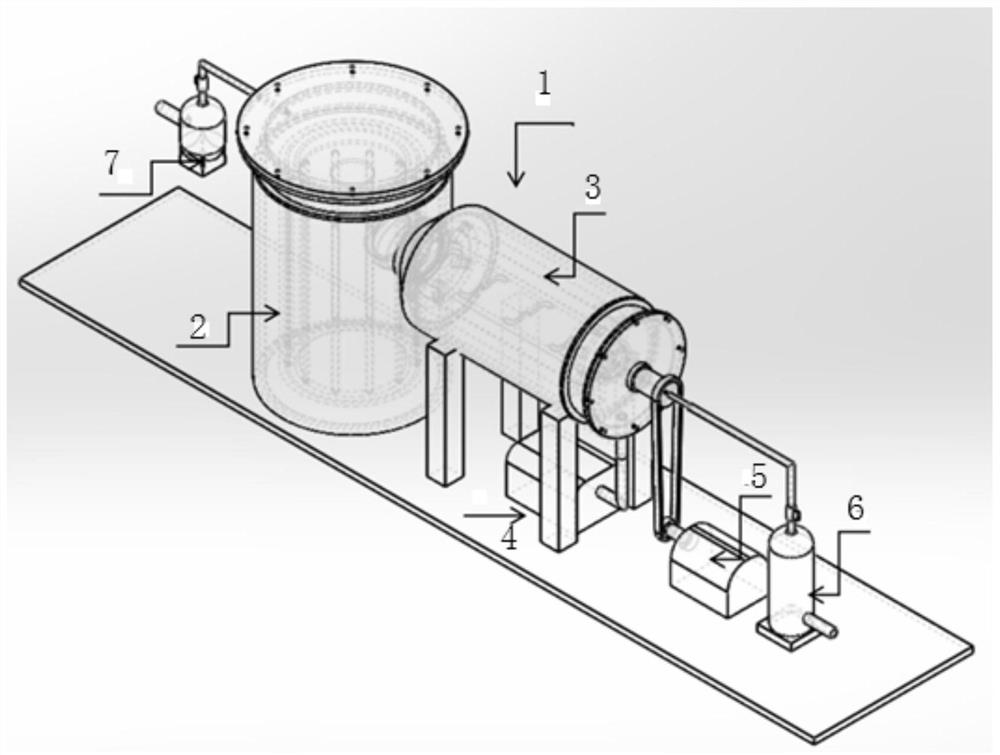

[0052] This embodiment provides a high-temperature device for preparing negative electrode materials for lithium-ion batteries. The high-temperature device includes a bin body 1 and a vacuum device 4 connected to the bin body, a transmission device 5, a gas mixing device 6, and an exhaust gas treatment device 7; The bin body 1 includes a vacuum reaction chamber 2 and a rotary collection chamber 3. The front end of the rotary collection chamber 3 is connected to the vacuum reaction chamber 2, and the rear end of the rotary collection chamber 3 is respectively connected to the vacuum device, the transmission device and the gas mixing device. The processing device 7 is connected to the vacuum reaction chamber; the vacuum reaction chamber 2 and the rotary collection chamber 3 are respectively equipped with independent heating devices, which can independently control the temperature of the vacuum reaction chamber and the rotary collection chamber.

[0053] The vacuum reaction chambe...

Embodiment 2

[0081] This embodiment provides a method for preparing a negative electrode material of a lithium ion battery. The method is specifically to prepare a negative electrode material for a lithium ion battery by compounding silicon oxide and other negative electrode materials. Using the high temperature device, the vacuum reaction chamber 2 The silicon oxide raw material is placed inside, and other negative electrode materials are placed in the rotary collection chamber 3 as the core material, and the reaction temperatures of the vacuum reaction chamber and the rotary collection chamber are respectively controlled, so that silicon oxide is deposited on the surface of the core material to form nano Level coating layer, after carbon coating in the high temperature device, the negative electrode material of lithium ion battery can be obtained.

[0082] The preparation method uses the above-mentioned high temperature device, comprising the following steps:

[0083] (1) Keep the vacuum...

Embodiment 3

[0090] This embodiment provides a method for preparing a lithium-ion battery negative electrode material, using the above-mentioned high-temperature device, comprising the following steps:

[0091] (1) Keep the vacuum tightness of the gas quick-connection pipeline 602 and the tail gas quick-connection pipeline 702, put silicon oxide raw material in the reaction chamber 201 of the vacuum reaction chamber, and install Enter the core material (metal germanium), and the mass ratio of the silicon oxide raw material to the core material is 1:1;

[0092] (2) Seal the first sealing flange 102, the fixing flange 3012, and the second sealing flange 103, and open the vacuum device 4 for vacuuming; when the degree of vacuum reaches 50-100Pa, open the transmission device 5 , the rotary collection chamber 3 rotates at a speed of 50r / min;

[0093] (3) The heating layer of the vacuum reaction chamber 2 is heated to 1400° C. to fully vaporize the silicon oxide raw material to obtain silicon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com