Preparation process of porous hollow ceramic adsorption ball

A technology of hollow ceramics and preparation technology, which is applied in the field of ceramic materials, can solve the problems of low utilization rate of ceramics, and achieve the effects of fast release, strong adsorption, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

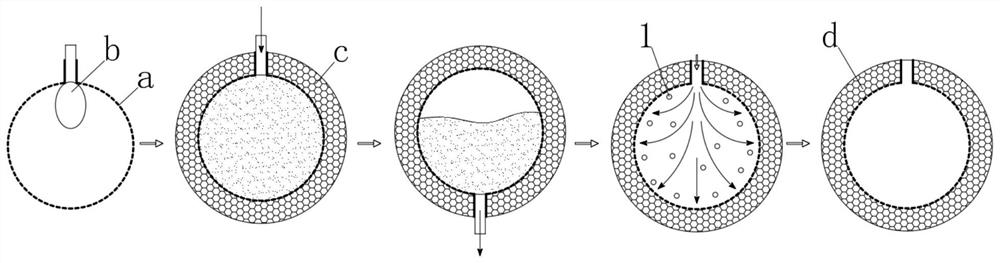

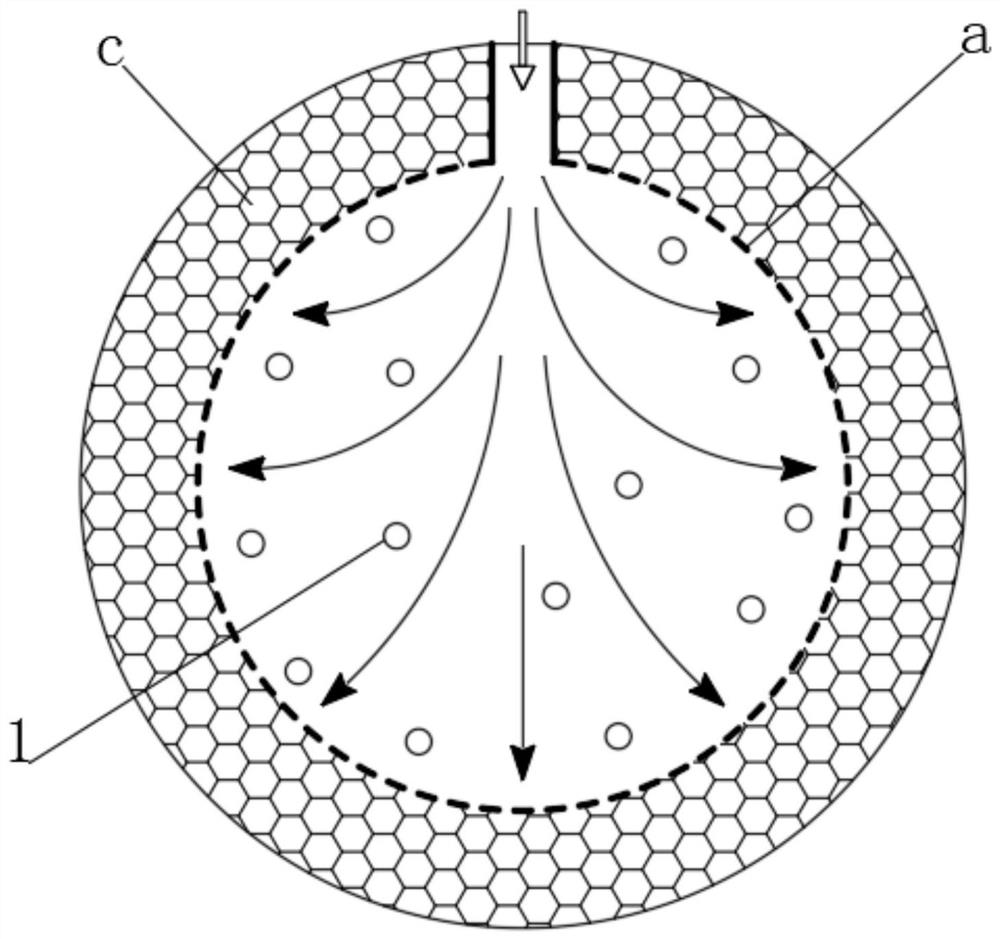

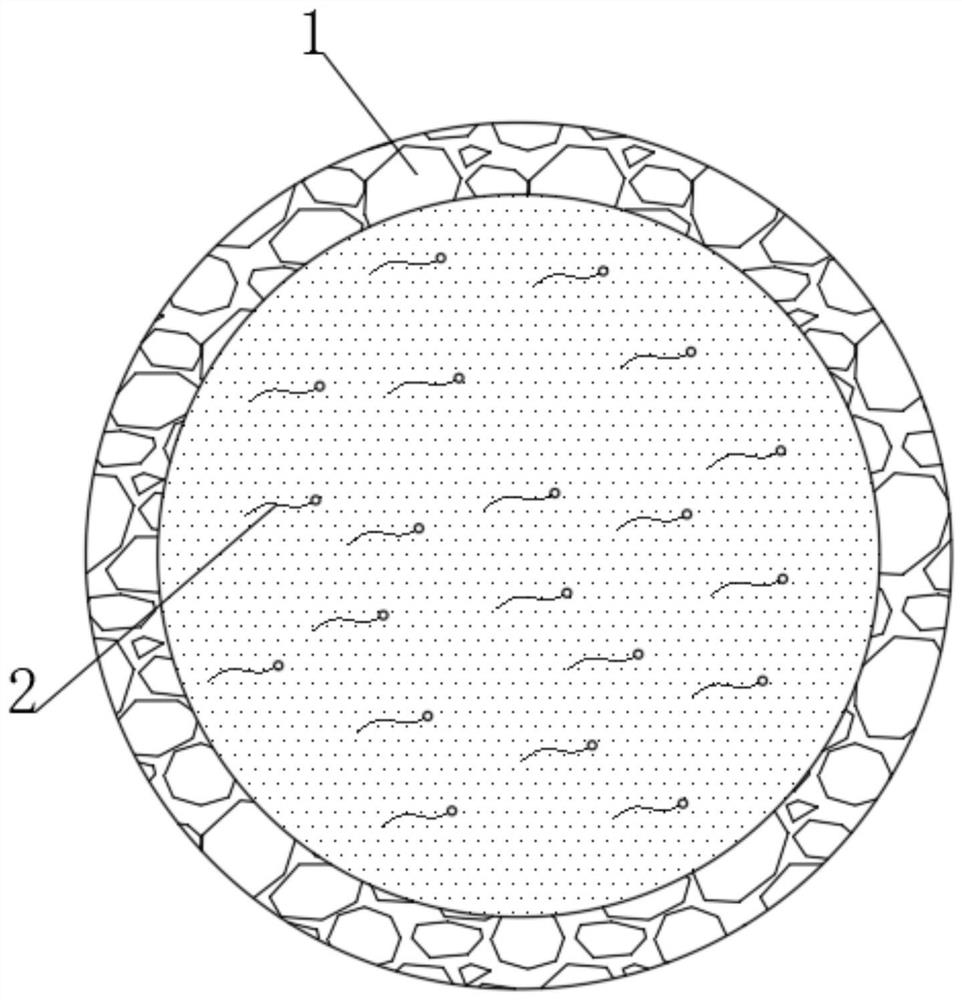

[0048] see figure 1 In the figure, a is a mesh steel ball, b is the inner false solid capsule, c is the pressed ceramic material layer wrapped outside the mesh steel ball, and d is the finished product of the porous hollow ceramic adsorption ball, which is a kind of porous hollow ceramic adsorption ball. The preparation process comprises the following steps:

[0049] S1, the coal gangue, bauxite and quartz are mixed and ball milled to obtain ceramic powder for subsequent use;

[0050] S2. Take the hollow mesh steel ball as the inner mold, then put the inner false solid bag inside the mesh steel ball, and fill the inner false solid bag with fine sand particles while inflating it until the inner false solid bag is completely attached. Attached to the inner wall of the mesh steel ball;

[0051] S3, wrapping the ceramic powder on the outer end of the mesh steel ball, and extruding to obtain a solid ceramic ball whose surface layer is a ceramic material layer;

[0052] S4. Stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com