H-GI-POF high-temperature optical fiber and preparation method thereof

An optical fiber, h-gi-pof technology, applied in the direction of light guide, cladding fiber, fiber chemical characteristics, etc., can solve the problems of high cost, small core diameter of glass fiber, complicated connection, etc., and achieve fast transmission speed and transmission delay. The effect of short time and large signal transmission bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

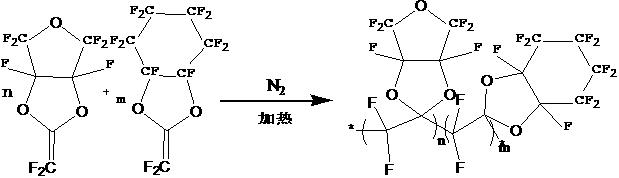

[0038] Such as image 3 As shown, the synthesis of high polymer X1

[0039] The high polymer X1 is synthesized according to the free radical polymerization route, and the free radical is provided by the thermal decomposition of perfluorodibenzoyl peroxide PFDBPO.

[0040] S101: Add n moles of monomer M8A: perfluoro-2-methyl-4,5-methyl ether group-1,3-dioxolane, m moles of monomer M8E: perfluoro-3- Methylene-2,4-dioxin bicyclo[4,3,0]nonane, initiator, wherein n:m=35-90:10-65; the initiator includes perfluorodibenzoyl peroxide , the mass percentage of the initiator is 0.05-0.15%;

[0041] That is, in a small reactor with good airtightness, add 244.8 grams (0.90mol) of M8A monomer and 35.6 grams (0.10mol) of M8E monomer, and then add 0.280 grams (0.1%, w / w) of the initiator;

[0042] S102: Stir and clean with nitrogen gas. After cleaning, the reactor is depressurized to 0.35-0.95 atmospheric pressure, and heated to 60-90°C for polymerization reaction. The reaction time is 20-4...

Embodiment 2

[0047] Such as image 3 As shown, the synthesis of high polymer X2

[0048] The high polymer X2 is synthesized according to the free radical polymerization route, and the free radical is provided by the thermal decomposition of perfluorodibenzoyl peroxide PFDBPO.

[0049] The difference between this example and Example 1 is: the molar mass of M8A monomer and M8E monomer, in this example, 217.6 grams (0.8 mol) of M8A monomer, 71.2 grams (0.2 mol) of M8E monomer, and 0.290 grams of initiator After the polymerization reaction, the high polymer X2 is obtained, the conversion rate of the high polymer X2 is calculated to be 77%, and the thermal decomposition temperature Td of the high polymer X2 in air is measured by thermogravimetric analysis TGA ≥ 300 °C, This shows that the thermal stability of the high polymer X2 is high.

Embodiment 3

[0051] Such as image 3 As shown, the synthesis of high polymer X3

[0052] The high polymer X3 is synthesized according to the free radical polymerization route, and the free radicals are provided by the thermal decomposition of perfluorobenzoyl peroxide PFDBPO.

[0053] The difference between this example and Example 1 is: the molar mass of M8A monomer and M8E monomer, in this example, 190.4 grams (0.7 mol) of M8A monomer, 106.8 grams (0.3 mol) of M8E monomer, and 0.297 g of initiator , high polymer X3 is obtained after the polymerization reaction, the conversion rate of the high polymer X3 is calculated to be 78%, and the thermal decomposition temperature Td of the high polymer X3 in air is measured by thermogravimetric analysis TGA ≥ 300 °C, This shows that the thermal stability of the high polymer X3 is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com