Contact lens material, contact lens containing contact lens material and preparation method of contact lens

A technology for contact lenses and raw materials, applied in glasses/goggles, instruments, optics, etc., can solve the problems of hydrogel contact lenses, such as tension, reduced toughness, low moisture content, uncomfortable wearing, etc., to prevent photochemical damage , the effect of increasing moisture content and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

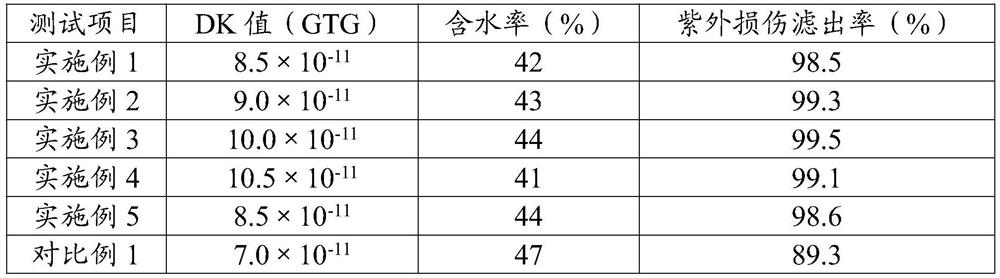

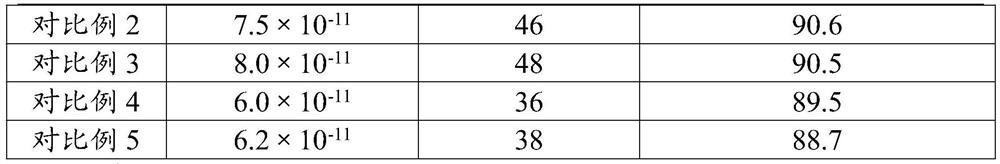

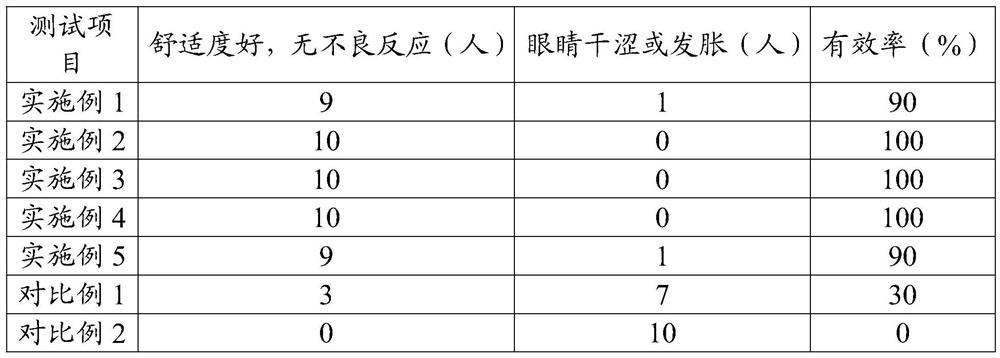

Examples

Embodiment 1

[0036]Contact lens material, comprising the following raw materials by weight: 70 g of hydroxyethyl methacrylate, 10 g of 2-methacryloyloxyethyl phosphorylcholine, 0.7 g of azophenyl methacrylate, ethylene glycol dimethacrylate 0.3g of ester, 0.25g of 3-(methacryloyloxy)propyltrimethoxysilane, 0.25g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl 2-acrylate, 0.25g of azobis Isobutyronitrile 0.2g, methacrylic acid 0.2g and sodium hyaluronate 0.1g.

[0037] The preparation method of contact lens is characterized in that, specifically comprises the following steps:

[0038] (1) Weighing raw materials: Weigh each raw material according to the parts by weight of the above-mentioned contact lens materials, mix and stir for 4 hours at a speed of 100 r / min to obtain a contact lens raw material solution, and set aside;

[0039] (2) Making molds:

[0040] A. Making the punch mold: Weigh an appropriate amount of polybutylene terephthalate (English name polybutyleneterephthalate; PBT for short) ...

Embodiment 2

[0047] Contact lens material, comprising the following raw materials by weight: 75 g of hydroxyethyl methacrylate, 15 g of 2-methacryloyloxyethyl phosphorylcholine, 0.7 g of azophenyl methacrylate, ethylene glycol dimethacrylate 0.4g of ester, 0.3g of 3-(methacryloyloxy)propyltrimethoxysilane, 0.25g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl 2-acrylate, 0.25g of azobis Isobutyronitrile 0.2g, methacrylic acid 0.2g and sodium hyaluronate 0.15g.

[0048] The preparation method of contact lens is the same as embodiment 1.

Embodiment 3

[0050] Contact lens material, including the following raw materials by weight: 77g of hydroxyethyl methacrylate, 20g of 2-methacryloyloxyethyl phosphorylcholine, 0.8g of azophenyl methacrylate, ethylene glycol dimethacrylate 0.4g of ester, 0.5g of 3-(methacryloyloxy)propyltrimethoxysilane, 0.3g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl 2-acrylate, 0.3g of azobis 0.3g of isobutyronitrile, 0.5g of methacrylic acid and 0.2g of sodium hyaluronate.

[0051] The preparation method of contact lens is characterized in that, specifically comprises the following steps:

[0052] (1) Weighing raw materials: Weigh each raw material according to the parts by weight of the above-mentioned contact lens materials, mix and stir for 5 hours at a speed of 150 r / min to obtain a contact lens raw material solution, and set aside;

[0053] (2) Making molds:

[0054] A. Making the punch mold: Weigh an appropriate amount of polybutylene terephthalate (English name polybutyleneterephthalate; PBT for shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com