A kind of near room temperature magnetic refrigeration manganese germanium based refrigeration material and preparation method thereof

A magnetic refrigeration, germanium-based technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem of unsatisfactory magnetocaloric effect, and achieve the effect of avoiding thermal hysteresis, optimizing Curie temperature, and optimizing magnetocaloric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

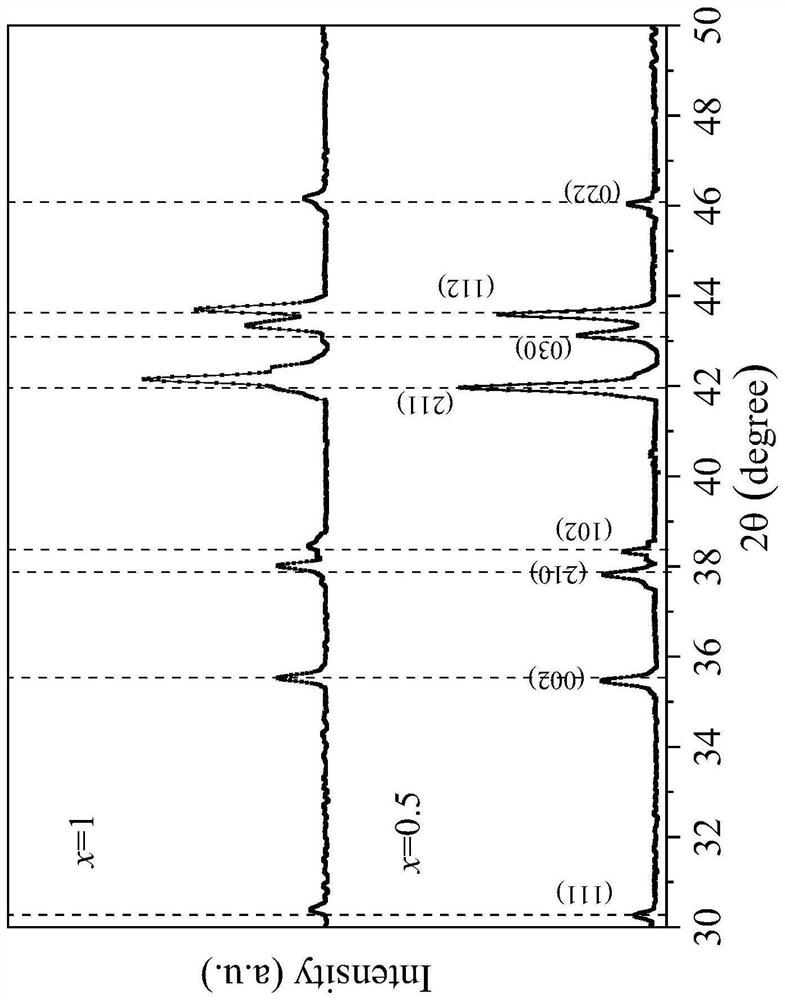

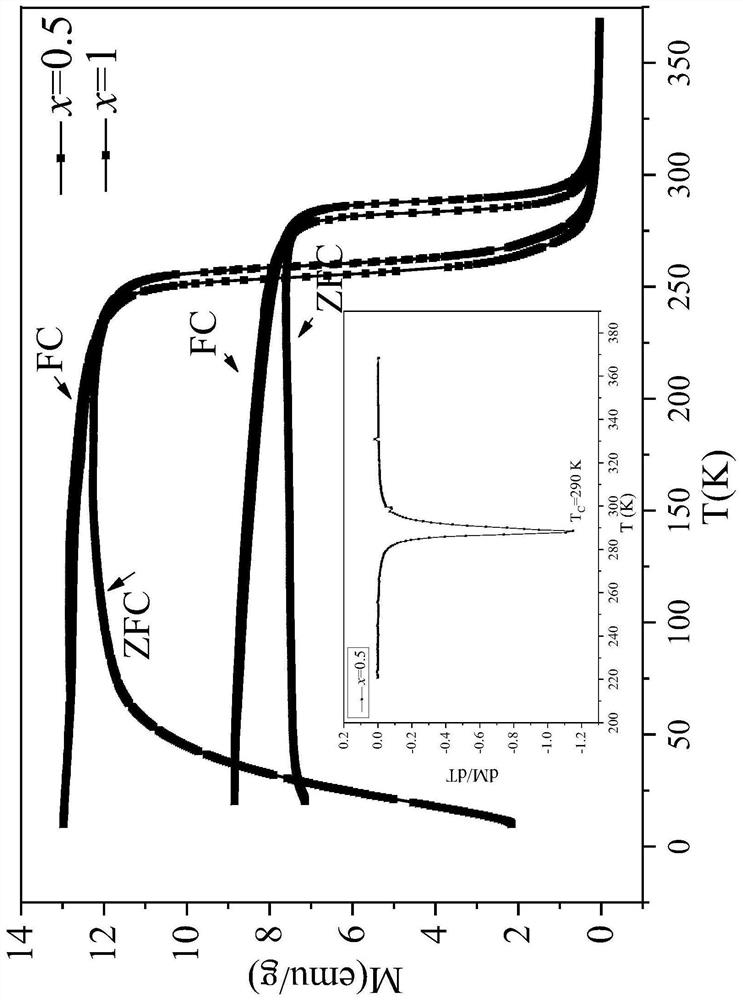

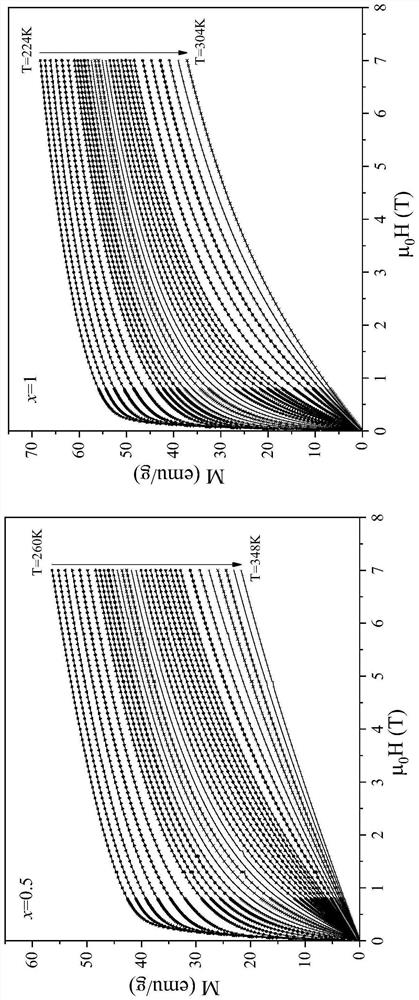

[0034] The purity of the experimental raw materials is 99.9%Mn, 99.99%Ge, 99.99%Ti, and the alloy is smelted by a vacuum arc furnace. 5 Ge 3-x Ti x (x are respectively 0.5, 1) The metering ratio of weighing the reaction raw materials is put into the electric arc furnace, and then the furnace is evacuated so that the degree of vacuum is lower than 10 -3 Pa, then pass in high-purity argon (99.999%) until the pressure is about 10Pa, repeat the above vacuuming and gas washing operation steps 3 times, use a current of about 30A to catch fire, move the electrode to the top of the sample and adjust the current to 70A Left and right until the sample is completely melted, and then reduce the current to 50A and smelt for half a minute. After the alloy is cooled, it is turned over, and the smelting is repeated 4 times to ensure the uniformity of the sample. Take out the cooled sample and put it into a high-temperature quartz glass test tube in a vacuum annealing furnace. The system is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com