Trivalent chromium plating solution, preparation method thereof and trivalent chromium plating method

A technology of trivalent chromium and chrome plating, applied in trivalent chromium plating solution and its preparation, in the field of trivalent chromium plating, which can solve problems such as whitening, reduction of chlorine gas precipitation, yellowing of trivalent chromium plating layer, etc., to reduce toxicity , Inhibition content, effect of process condition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

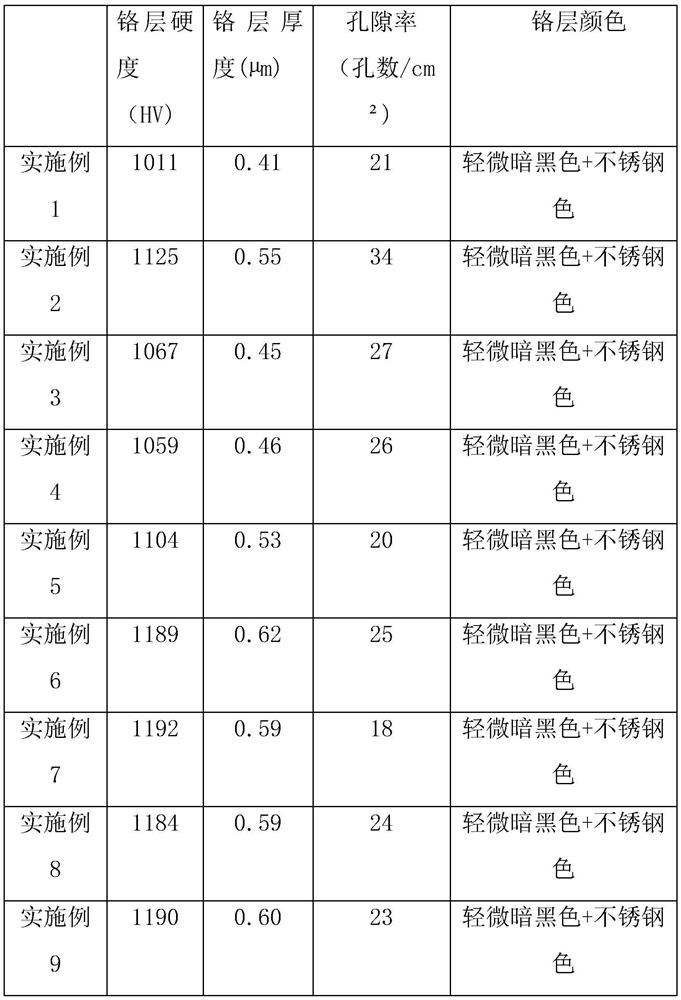

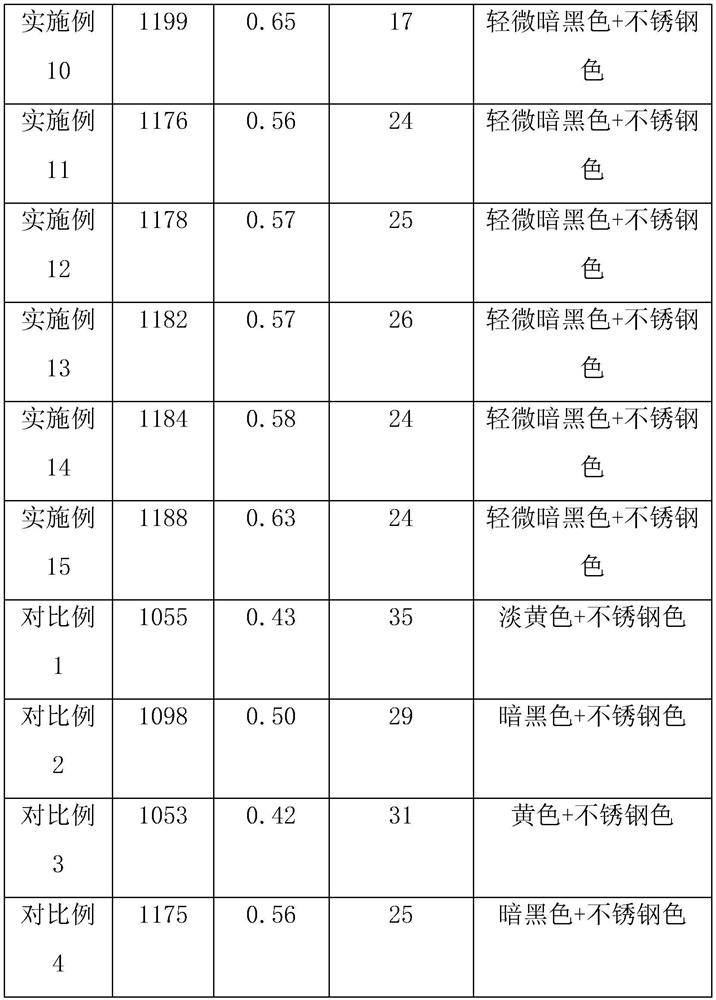

Examples

preparation example 1

[0052] A kind of trivalent chromium plating liquid of this preparation example is made up of the component of following weight: Chromium trichloride 90g, potassium chloride 200g, boric acid 6.0g, malic acid 40g, alkylsulfonate sodium 0.05g, iron powder 0.2g, 664g of deionized water.

[0053] The preparation method of a kind of trivalent chrome plating liquid of this preparation example comprises the steps:

[0054] Step 1: adding potassium chloride and boric acid in corresponding parts by weight into an electroplating tank filled with deionized water at 50°C, and stirring until completely dissolved;

[0055] Step 2: Add chromium trichloride of corresponding parts by weight into the electroplating tank and stir until completely dissolved;

[0056] Step 3: Electrolyze the electrolysis net for 5 hours, and the current is 15A during the electrolysis of the electrolysis net;

[0057] Step 4: Add malic acid and sodium alkylsulfonate in corresponding parts by weight to the electropla...

preparation example 2

[0060] A kind of trivalent chromium plating liquid of this preparation example is made up of the component of following weight: 100g of chromium trichloride, 225g of potassium chloride, 40g of boric acid, 50g of malic acid, 0.07g of sodium alkylsulfonate, 0.3g of iron powder, 685g of ionized water.

[0061] The preparation method of a kind of trivalent chrome plating liquid of this preparation example comprises the steps:

[0062] Step 1: Add potassium chloride and boric acid in corresponding parts by weight into an electroplating tank filled with deionized water at 55°C, and stir until completely dissolved;

[0063] Step 2: Add chromium trichloride of corresponding parts by weight into the electroplating tank and stir until completely dissolved;

[0064] Step 3: Electrolyze for 6 hours with an electrolysis net with a current of 20A;

[0065] Step 4: Add malic acid and sodium alkylsulfonate in corresponding parts by weight to the electroplating tank and stir to dissolve;

...

preparation example 3

[0068] A kind of trivalent chromium plating liquid of this preparation example is made up of the component of following weight: 120g of chromium trichloride, 250g of potassium chloride, 80g of boric acid, 60g of malic acid, 0.1g of sodium alkylsulfonate, 0.4g of iron powder, 490g of ionized water.

[0069] The preparation method of a kind of trivalent chrome plating liquid of this preparation example comprises the steps:

[0070] Step 1: Add potassium chloride and boric acid in corresponding parts by weight into an electroplating tank filled with deionized water at 60°C, and stir until completely dissolved;

[0071] Step 2: Add chromium trichloride of corresponding parts by weight into the electroplating tank and stir until completely dissolved;

[0072] Step 3: Electrolyze for 8 hours with an electrolysis net with a current of 30A;

[0073] Step 4: Add malic acid and sodium alkylsulfonate in corresponding parts by weight to the electroplating tank and stir to dissolve;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com