Method for analyzing and detecting octadecyl dimethyl betaine in crude oil by liquid chromatography

A technique for analyzing octadecyldimethyl beet and liquid chromatography, which is applied in the field of analytical chemistry, can solve the problems of rare betaine amphoteric surfactants and the like, and achieves the effects of high sensitivity and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of samples to be tested

[0036] Take 2 mL each of the three crude oil samples to be tested, 6AT235, 6AT216, and 6A237, dilute them with 2 mL of n-hexane, mix well, and then use 4 mL of ethanol / water mixture to extract the betaine surface activity in the crude oil / n-hexane mixture. agent, let it stand for stratification, take the ethanol / water extract, and inject 20 µL.

[0037] 2. Detection

[0038] Chromatographic conditions: chromatographic column: 25 cm C18 chromatographic column; mobile phase: acetonitrile / water mixture (volume ratio 3 / 2), flow rate 1.0 mL / min; detector: mass spectrometer detector, ESI source, positive mode detection;

[0039] Under the above chromatographic conditions, 20 μL of the ethanol / water extract was injected, and there was no octadecyldimethyl betaine chromatographic peak around 11.0 min, which proved that none of the three crude oils contained octadecyldimethyl betaine .

Embodiment 2

[0041] 1. Sample preparation

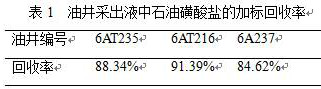

[0042] Add 100 mg / L octadecyl dimethyl betaine to 6AT235, 6AT216, and 6A237 three crude oils respectively, take 2 mL of the above-mentioned spiked crude oil samples, dilute with 2 mL of n-hexane, mix well, and then use 4 Extract the spiked betaine surfactant in the crude oil / n-hexane mixed solution with mL ethanol / water mixture, let stand to separate the layers, take the ethanol / water extract, and inject 20 µL.

[0043] 2. Detection

[0044] Chromatographic conditions: with embodiment one;

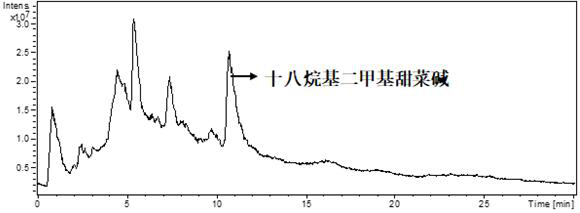

[0045] Under the above chromatographic conditions, 20 μL of ethanol / water extract was injected, and octadecyldimethyl betaine peaked around 11.0 min (see figure 2 ), measure the chromatographic peak area of octadecyldimethyl betaine in different crude oils;

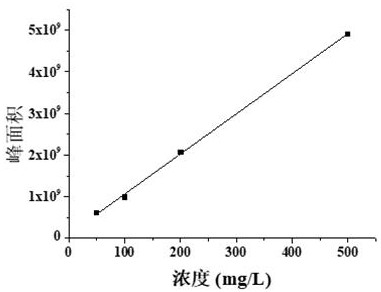

[0046] According to the linear relationship: Y = 98992000 + 9638310 X, the concentrations of octadecyldimethyl betaine in the three crude oils of 6AT235, 6AT216 and 6A237 are calculated, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com