Environment-friendly flame-retardant cold-resistant wear-resistant cable and manufacturing method and application thereof

A manufacturing method and an environmentally friendly technology, applied in cable/conductor manufacturing, insulated cables, power cables, etc., can solve problems such as tight metal hydroxide wrapping, lower mechanical properties of polyurethane, and shorten service life of cables, so as to improve internal friction Effects of generating heat, enhancing oxidation resistance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

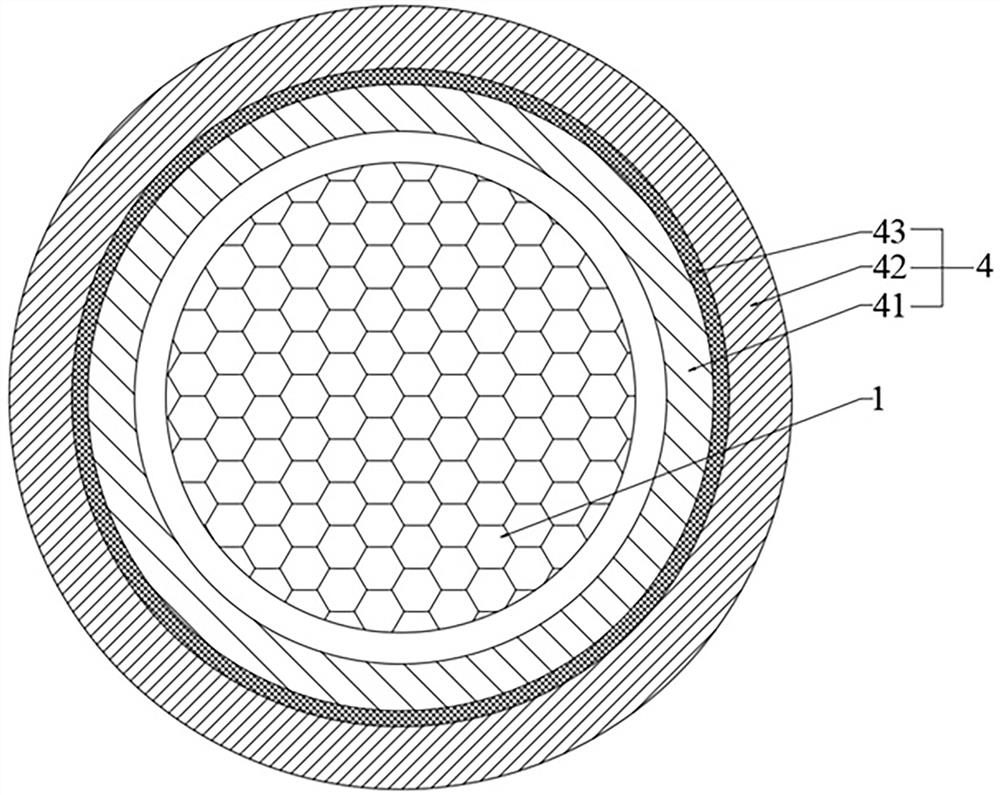

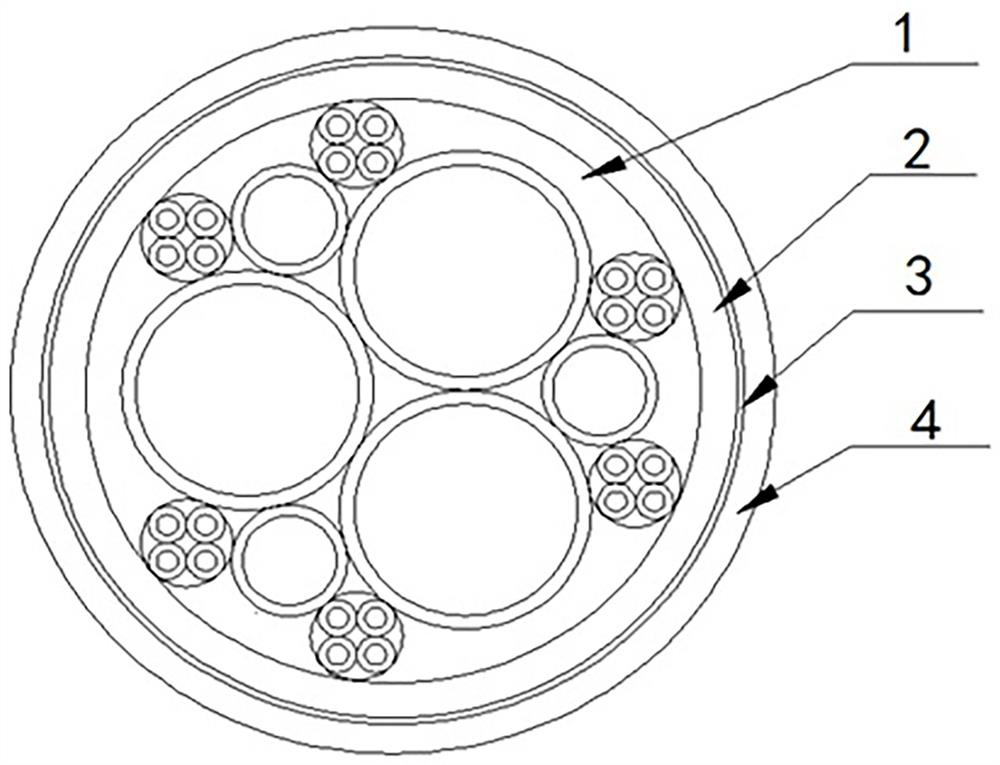

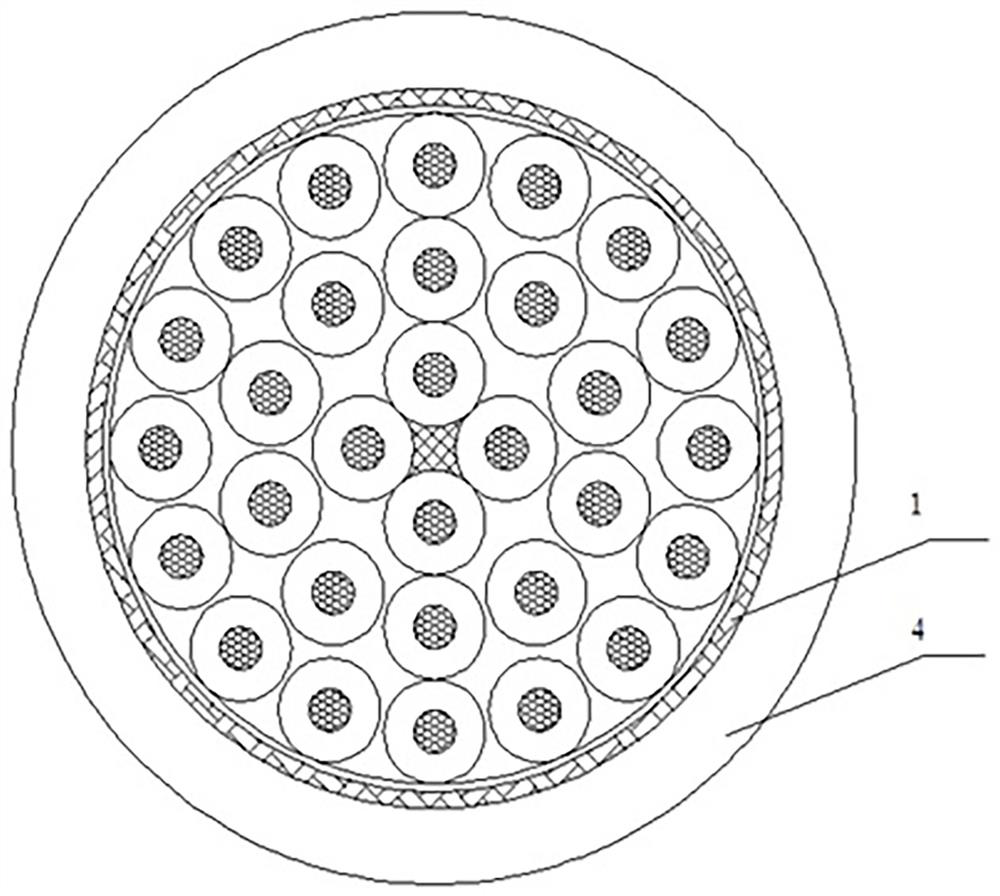

[0054] Such as figure 1 As shown, an environmentally friendly, flame-retardant, cold-resistant and wear-resistant cable includes a cable core 1 and an outer protective layer 4 coated on the outside of the cable core 1; the outer protective layer 4 includes a ternary environmentally friendly flame-retardant layer 42 and a polyurethane layer 41 ; The ternary environment-friendly flame-retardant layer 42 and the polyurethane layer 41 are cross-linked with each other through a cross-linked structure 43; It is formed by interlacing, and the intersection of the polyurethane fiber and the ternary environmentally friendly flame-retardant fiber is fixed together by a hot-melt process; the cross-linking structure is set by using the polyurethane fiber and the ternary environmentally friendly flame-retardant fiber interlaced 43 , using the cross-linked structure 43 to fully integrate the polyurethane layer 41 and the ternary environmental protection flame-retardant layer 42 to realize th...

Embodiment 2

[0072] The ternary environmental protection flame retardant layer 42 is changed to include 100 parts by mass of thermoplastic polyurethane elastomer, 36.9 parts of nano-catalytic activity synergistic ternary composite flame retardant, 1 part of auxiliary crosslinking agent TAIC, 0.5 parts of polytetrafluoroethylene lubricant, 0.7 parts of butylated hydroxytoluene (BHT) antioxidant, 7 parts of PU-80 and 2 parts of dioctyl sebacate plasticizer;

[0073] The nano catalytic activity synergistic ternary compound flame retardant is changed to include the first element of organic flame retardant, the second element of metal hydroxide flame retardant, the third element of multi-component coupling compound agent and mesoporous Materials; the organic flame retardant is 1 part of ammonium polyphosphate and 0.4 part of tricresyl phosphate; the metal hydroxide flame retardant is 0.8 part of magnesium hydroxide; The multi-component coupling agent is selected from 19.5 parts by mass of KH 55...

Embodiment 3

[0081] The ternary environmental protection flame retardant layer 42 is changed to include 100 parts by mass of thermoplastic polyurethane elastomer, 16.15 parts of nano-catalytic activity synergistic ternary composite flame retardant, 0.5 parts of auxiliary crosslinking agent TAIC, 2 parts of polytetrafluoroethylene lubricant, 0.9 parts of butylated hydroxytoluene (BHT) antioxidant, 7 parts of PU-80 and 1 part of dioctyl sebacate plasticizer;

[0082] The nano catalytic activity synergistic ternary compound flame retardant is changed to include the first element of organic flame retardant, the second element of metal hydroxide flame retardant, the third element of multi-component coupling compound agent and mesoporous Material; The described organic flame retardant selects the melamine of 2.5 parts, the tributyl phosphate of 0.6 part for use in mass components; The aluminum hydroxide of described metal hydroxide flame retardant selects 3.5 parts; As the compounding agent, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com