Semitransparent polymer solar battery and production method thereof

A technology of solar cells and polymers, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of inability to intelligently change devices and limit the wide application of semi-transparent polymer solar cells, and achieve enhanced photon trapping, Effects of Improving Short-Circuit Current Density and Photoelectric Conversion Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

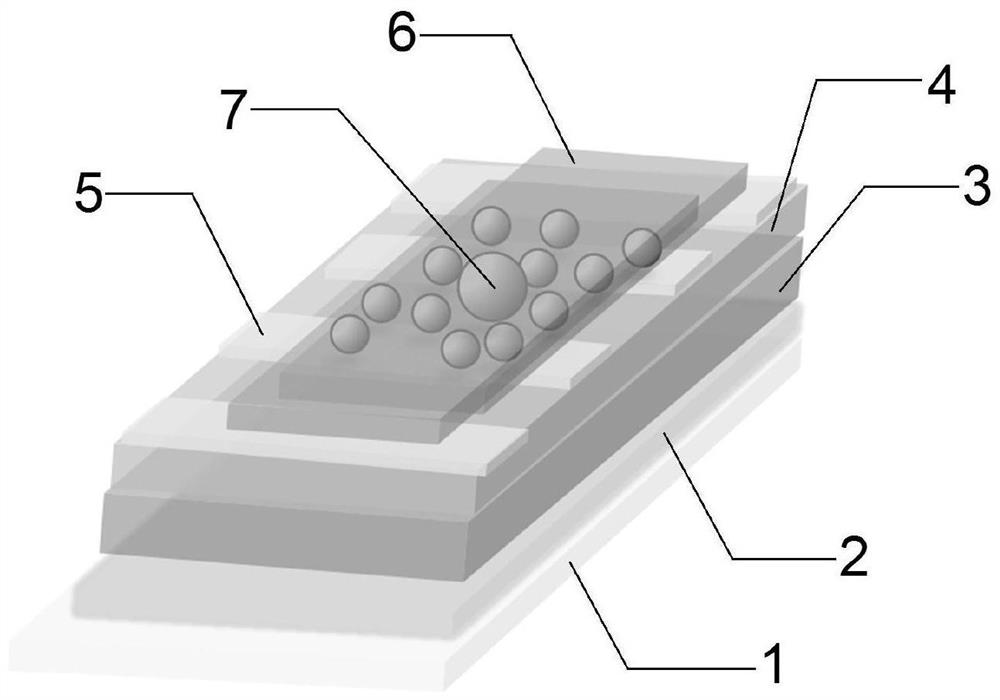

[0043] The present invention also provides a method for preparing the semitransparent polymer solar cell described in the above technical solution, comprising the following steps:

[0044] a) On the surface of the transparent substrate covered with ITO film, the electron transport layer, active layer, hole transport layer, metal electrode layer and Nb 2 o 5 film layer;

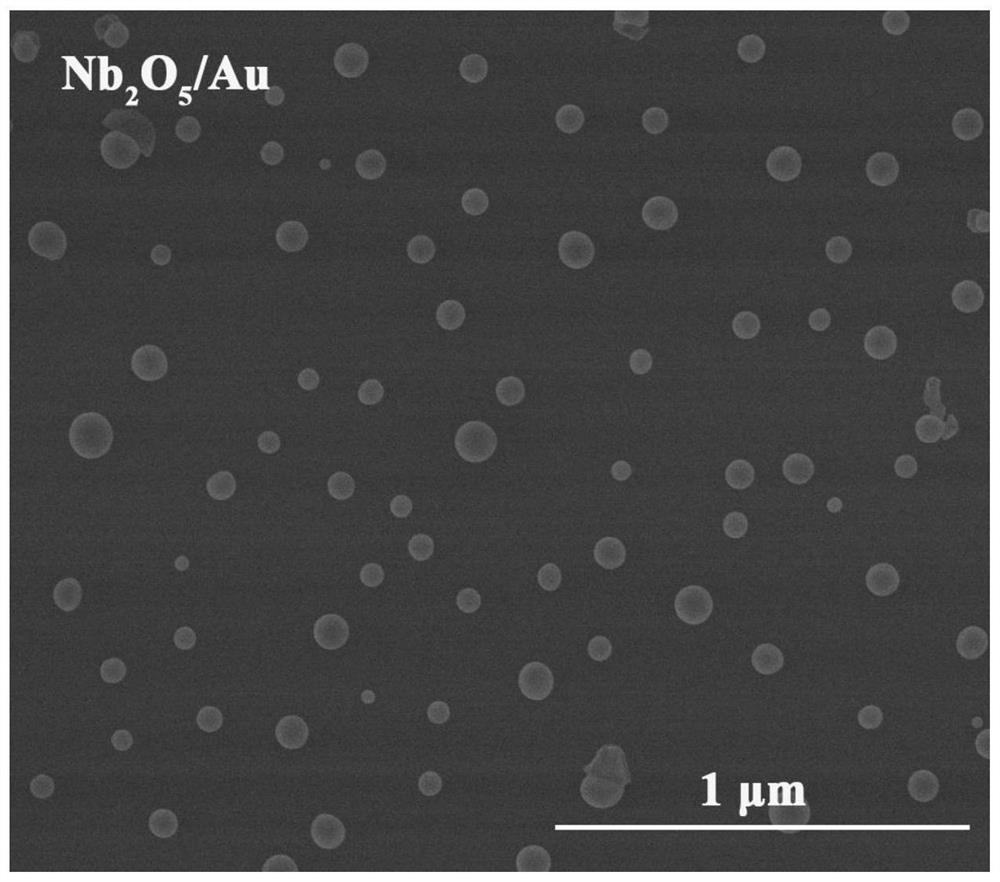

[0045] b) in the Nb 2 o 5 The surface of the film layer is coated with a solution containing Au nanoparticles and dried to obtain a translucent polymer solar cell.

[0046] In the preparation method provided by the present invention, firstly, the electron transport layer, the active layer, the hole transport layer, the metal electrode layer and the Nb 2 o 5 Film layer, its specific setting process preferably comprises the following steps:

[0047] a1) coating a solution containing an electron transport material on the surface of the transparent substrate covered with an ITO film, and annealing to form an...

Embodiment 1

[0067] A semi-transparent polymer solar cell is prepared according to the following steps:

[0068] 1) Clean the conductive glass covered with ITO with detergent (commercially available detergent), ultrapure water, acetone, and ethanol for 15 minutes, and then dry the cleaned substrate with nitrogen and then treat it with ultraviolet light for 15 minutes;

[0069] 2) SnO 2 The 15wt% hydrocolloid dispersion was diluted with ultrapure water, the dilution volume ratio was 1:13, and stirred for 30 minutes to fully disperse; then it was spin-coated on the ITO glass substrate covered with a rotating speed of 3000rpm, and the spin-coating time was 30s; Finally, anneal at 150°C for 30 minutes, and the obtained film is the electron transport layer, and the thickness of the electron transport layer is about 20 nm;

[0070] 3) Mix the donor material J71 and the acceptor material IEICO-4F with a mass ratio of 1:1.5 and dissolve them in a mixed solvent of chlorobenzene and 1-chloronaphtha...

Embodiment 2

[0077] A semi-transparent polymer solar cell is prepared according to the following steps:

[0078] 1) Clean the conductive glass covered with ITO with detergent (commercially available detergent), ultrapure water, acetone, and ethanol for 15 minutes, and then dry the cleaned substrate with nitrogen and then treat it with ultraviolet light for 15 minutes;

[0079] 2) SnO 2 The 15wt% hydrocolloid dispersion was diluted with ultrapure water, the dilution volume ratio was 1:13, and stirred for 30 minutes to fully disperse; then it was spin-coated on the ITO glass substrate covered with a rotating speed of 3000rpm, and the spin-coating time was 30s; Finally, anneal at 150°C for 30 minutes, and the obtained film is the electron transport layer, and the thickness of the electron transport layer is about 20 nm;

[0080] 3) Mix the donor material PM6 and the acceptor material Y6 with a mass ratio of 1:1.2 and dissolve them in a mixed solvent of chloroform and 1-chloronaphthalene (0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com