Friction nanometer generator and preparation method thereof

A nanogenerator and friction layer technology, applied in the direction of triboelectric generators, can solve the problems of affecting electric output performance and low triboelectric charge transfer amount, and achieve the effect of improving electric output performance, increasing charge transfer amount, and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

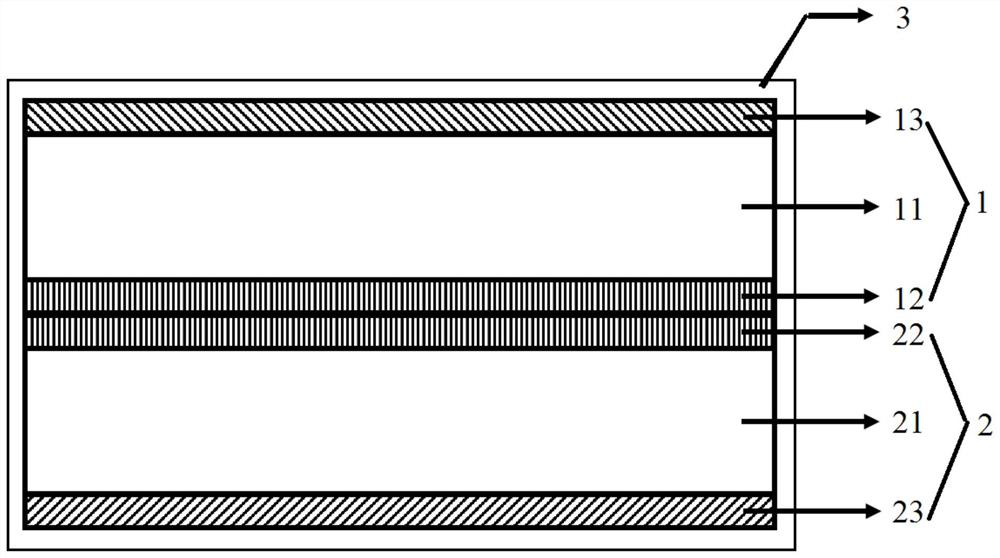

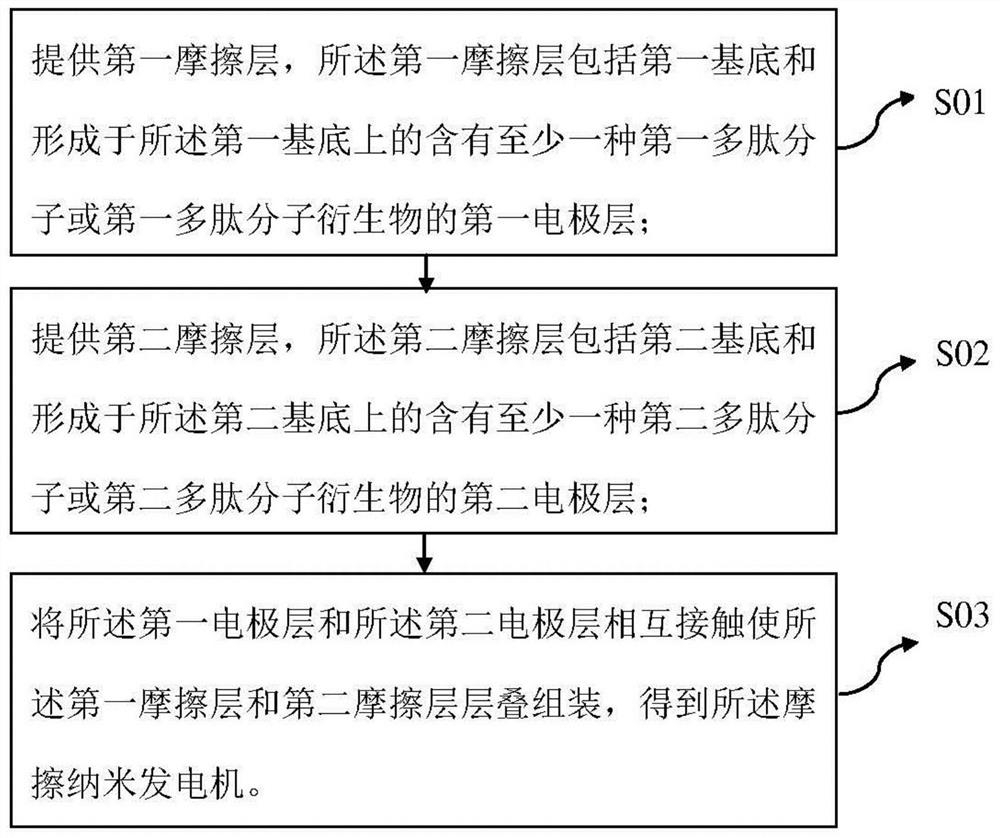

[0051] A kind of triboelectric nanogenerator, its preparation step comprises:

[0052]Firstly, the base layer and encapsulation layer materials are prepared. The first substrate and the second substrate layer of the triboelectric nanogenerator are respectively composed of polycaprolactone (PCL) and sodium alginate materials. The preparation method of the PCL membrane material is as follows: a certain amount of PCL polymer material is weighed and dissolved in a dichloromethane solution, and stirred evenly to form a homogeneous solution with a mass fraction of 10%. Then add the PCL solution into a clean glass plate, let it stand at room temperature to remove air bubbles, and then place it in a vacuum oven at 80°C for 12 hours to obtain a flat PCL film material for later use. Similarly, the preparation method of the sodium alginate membrane material is as follows: first configure the acetic acid solution with a volume fraction of 1%, then weigh a certain mass of sodium alginate ...

Embodiment 2

[0057] A kind of triboelectric nanogenerator, its preparation step comprises:

[0058] Firstly, the base layer and encapsulation layer materials are prepared. The first substrate and the second substrate layer of the triboelectric nanogenerator are respectively composed of polylactic acid-glycolic acid copolymer (PLGA) and polyvinyl alcohol (PVA) materials. The preparation method of the PLGA membrane material is as follows: a certain amount of PLGA polymer material is weighed and dissolved in a dichloromethane solution, and stirred evenly to form a homogeneous solution with a mass fraction of 10%. The PLGA solution was then added to a clean glass plate, left to stand at room temperature to remove air bubbles, and then placed in a vacuum oven at 80°C for 12 hours to obtain a flat PLGA film material for later use. Similarly, the preparation method of the PVA film material is as follows: Weigh a certain mass of PVA material and add it into deionized water, heat and stir evenly t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com