Immunodeficient mouse feed and preparation process thereof

A technology for immunodeficiency mice and feed, applied in animal feed, animal feed, food processing, etc., can solve problems affecting tumor and immunology research, difficulty in feeding and breeding, weak constitution of young mice, etc., to achieve good absorption and reproduction The effect of increasing the rate and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

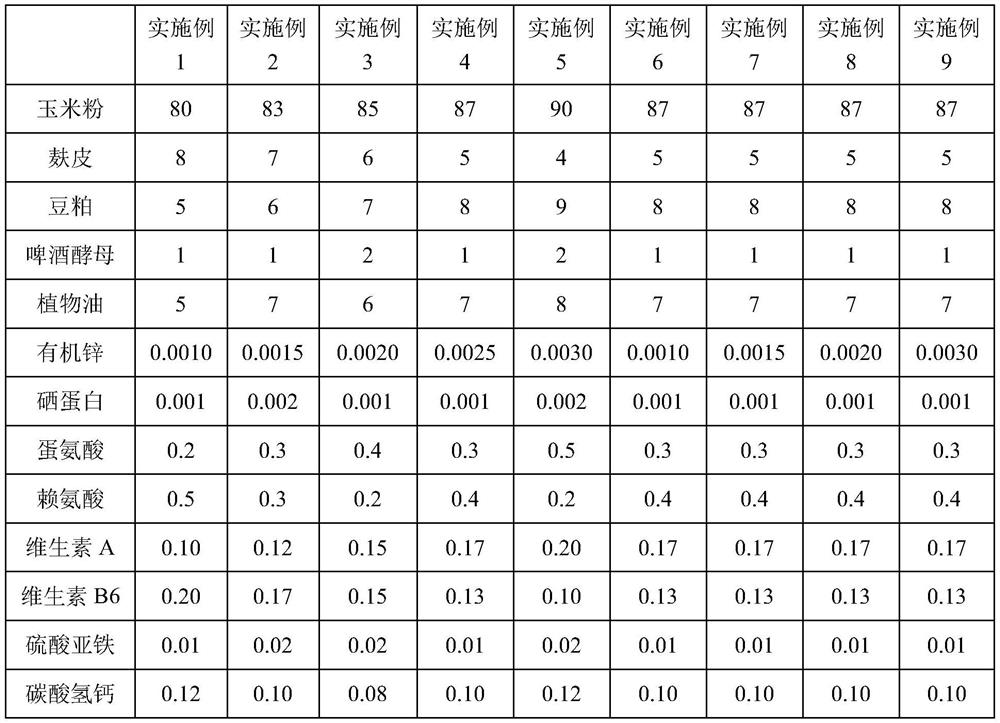

Examples

preparation example 1

[0043] A kind of organozinc, its preparation steps are as follows:

[0044] 1) Add 0.5kg of iminodiacetonitrile to 10kg of tetrahydrofuran, stir until dissolved, raise the temperature to 50°C, and then add 0.45kg of epichlorohydrin dropwise at a rate of 0.5mL / min. After the dropwise addition, continue Stir the reaction for 3 hours, then add 1.9 L of 3 mol / L sodium hydroxide solution, stir the reaction for 2 hours, then dropwise add 3 mol / L hydrochloric acid solution, adjust its pH to 7, to obtain a mixed solution, and carry out rotary evaporation of the mixed solution, Obtain solid A;

[0045] 2) Add solid A to 20kg of distilled water, stir until dissolved, and then add 5.2kg of chitosan oligosaccharides. Chitosan oligosaccharides are added in 5 times on average, and the time interval between two adjacent additions is 30min. After the addition is complete, continue After stirring and reacting for 2 hours, solid sodium hydroxide was added to adjust its pH to 9 to obtain a mixe...

preparation example 2

[0049] A kind of organozinc, its preparation steps are as follows:

[0050]1) Add 0.6kg of iminodiacetonitrile to 12kg of tetrahydrofuran, stir until dissolved, raise the temperature to 55°C, and then add 0.50kg of epichlorohydrin dropwise at a rate of 1.0mL / min. After the dropwise addition, continue Stir the reaction for 3.5 hours, then add 2.2 L of sodium hydroxide solution with a concentration of 3.5 mol / L, stir and react for 2.5 hours, then add dropwise a 3.5 mol / L hydrochloric acid solution, adjust its pH to 8, and obtain a mixed solution. Perform rotary evaporation to obtain solid A;

[0051] 2) Add solid A to 25kg of distilled water, stir until dissolved, then add 5.5kg of chitosan oligosaccharides, the addition of chitosan oligosaccharides is divided into 6 times on average, and the time interval between two adjacent additions is 35min. After the addition is complete, continue After stirring and reacting for 2.5 hours, solid sodium hydroxide was added to adjust the pH...

preparation example 3

[0055] A kind of organozinc, its preparation steps are as follows:

[0056] 1) Add 0.7kg of iminodiacetonitrile to 15kg of tetrahydrofuran, stir until dissolved, raise the temperature to 60°C, and then add 0.55kg of epichlorohydrin dropwise at a rate of 1.5mL / min. After the dropwise addition, continue Stir the reaction for 4 hours, then add 2.0 L of sodium hydroxide solution with a concentration of 4 mol / L, stir the reaction for 3 hours, then add dropwise 3 mol / L hydrochloric acid solution, adjust its pH to 7, and obtain a mixed solution, which is rotatively evaporated, Obtain solid A;

[0057] 2) Add solid A to 30kg of distilled water, stir until dissolved, and then add 6.0kg of chitosan oligosaccharides. Chitosan oligosaccharides are added in 7 times on average, and the time interval between two adjacent additions is 40min. After the addition is complete, continue After stirring and reacting for 3 hours, solid sodium hydroxide was added to adjust its pH to 9 to obtain a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com