Piezoelectric catalytic degradation and ammonia synthesis catalyst and preparation method and application thereof

A catalytic degradation and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of impracticability and limited application range, and achieve the improvement of piezoelectric catalytic synthesis of ammonia and piezoelectric Effect of degrading dye properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

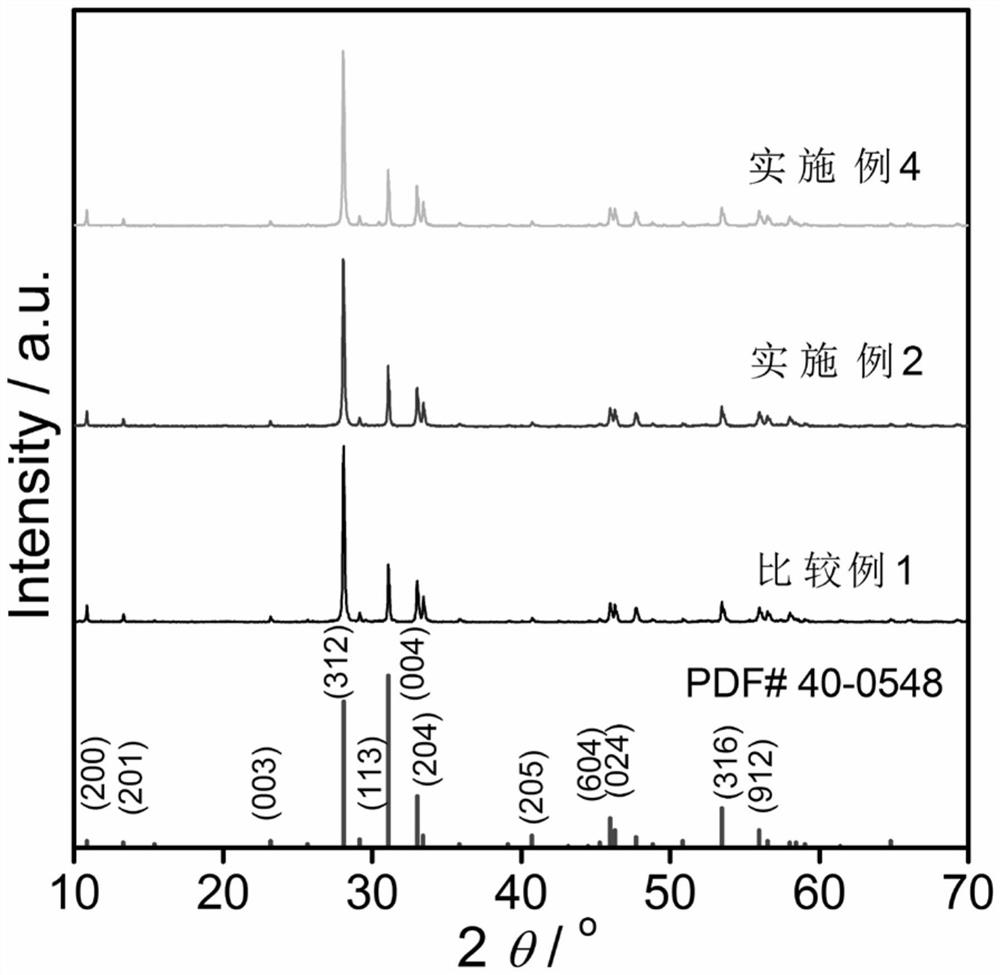

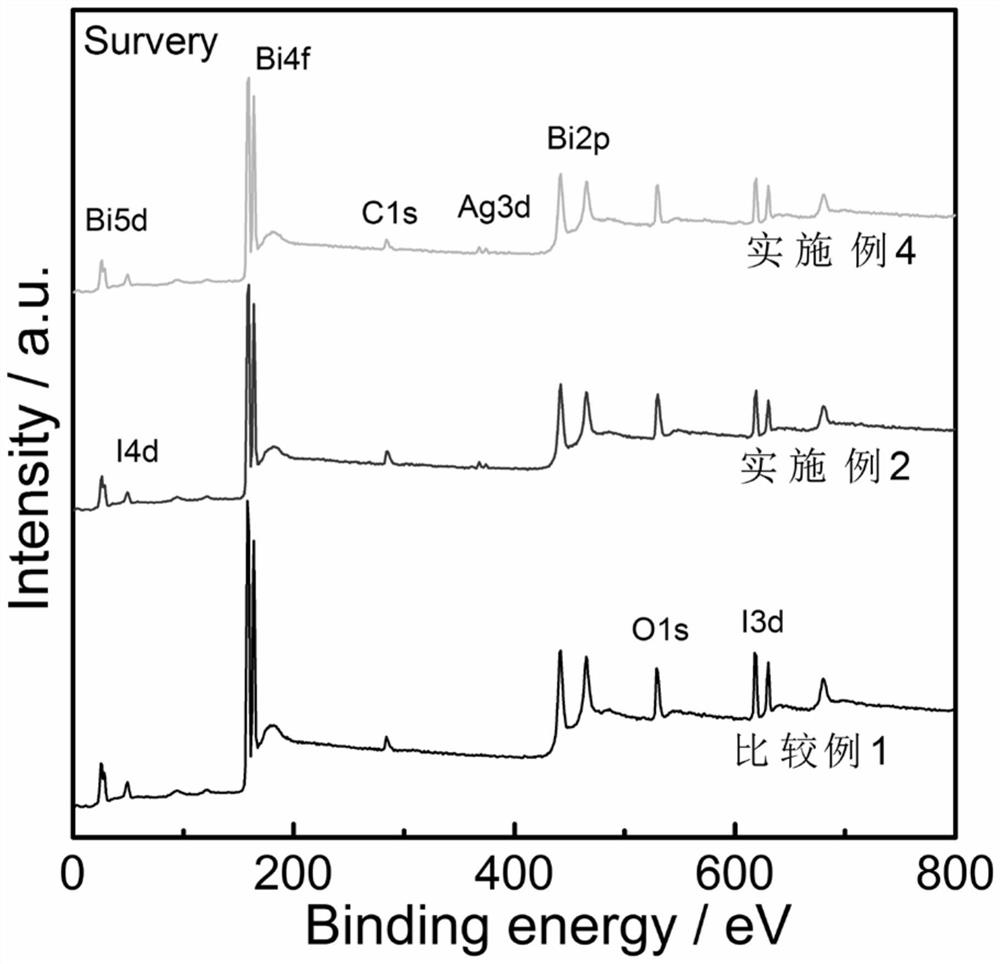

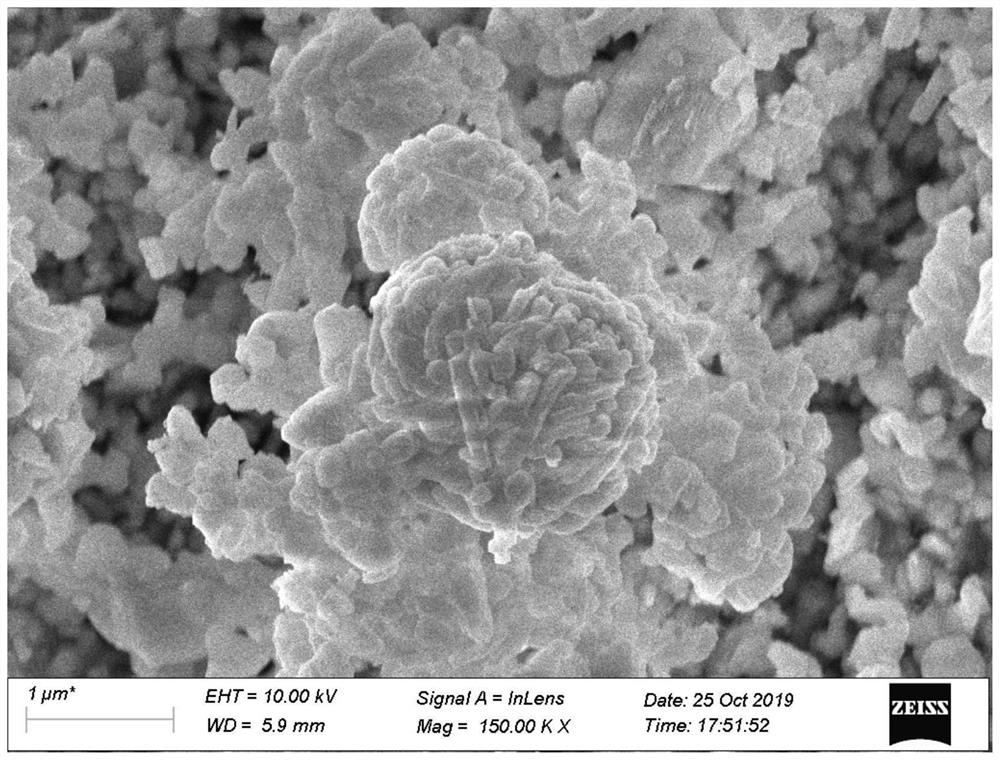

[0033] This embodiment provides a method for preparing a catalyst for piezoelectric catalytic degradation and synthesis of ammonia, the steps of which include:

[0034] 1) Weigh 0.970g of bismuth nitrate pentahydrate and 0.332g of potassium iodide, respectively pour it into a beaker containing 20mL of ethylene glycol, and stir on a magnetic stirrer for 30 minutes. Then the potassium iodide solution was added dropwise into the beaker containing the bismuth nitrate pentahydrate solution, and stirred on a magnetic stirrer for 30 minutes to fully dissolve it. Then the mixed solution was transferred to a 100 mL polytetrafluoroethylene autoclave, and the autoclave was sealed in a stainless steel tank, and hydrothermally reacted at 160° C. for 17 hours. After hydrothermal heating and natural cooling, the obtained precipitate was washed with water and alcohol, dried at 60°C for 24 hours, and the evaporated sample was transferred to a mortar for grinding for 30 minutes to obtain a prec...

Embodiment 2

[0037] This embodiment provides a method for preparing a catalyst for piezoelectric catalytic degradation and synthesis of ammonia, the steps of which include:

[0038] 1) with the step of (1) in embodiment 1

[0039] 2) Weigh 0.662g of silver nitrate and configure it into a silver nitrate solution with a concentration of 6.62mg / mL. Then weigh 1.000g of Bi 5 o 7 1, it is poured into the beaker that 10mL methanol and 40mL deionized water are housed, and the silver nitrate solution that measures 0.5mL is added this beaker, while stirring in the dark, logical nitrogen 40 minutes. After the nitrogen flow was stopped, the beaker was placed under a 300W xenon lamp and illuminated for 30 minutes while stirring. After the light is finished, the obtained precipitate is washed with water and alcohol, dried at 60°C for 24 hours, and the evaporated sample is transferred to a mortar and ground for 30 minutes to obtain the target product 2.5%Ag / Bi 5 o 7 I.

Embodiment 3

[0041]This embodiment provides a method for preparing a catalyst for piezoelectric catalytic degradation and synthesis of ammonia, the steps of which include:

[0042] 1) with the step of (1) in embodiment 1

[0043] 2) Weigh 0.662g of silver nitrate and configure it into a silver nitrate solution with a concentration of 6.62mg / mL. Then weigh 1.000g of Bi 5 o 7 1, it is poured into the beaker that 10mL methanol and 40mL deionized water are housed, and the silver nitrate solution that measures 1.0mL is added this beaker, while stirring in the dark, logical nitrogen 40 minutes. After the nitrogen flow was stopped, the beaker was placed under a 300W xenon lamp and illuminated for 30 minutes while stirring. After the light is finished, wash the obtained precipitate with water and alcohol, dry at 60°C for 24 hours, transfer the evaporated sample to a mortar and grind for 30 minutes to obtain the target product 5%Ag / Bi 5 o 7 I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com