A kind of magnesium alloy building formwork semi-solid die casting and double fluorination joint manufacturing method

A construction formwork and manufacturing method technology, applied in the direction of metal material coating process, etc., can solve the problems that the gas in the formwork cavity cannot be discharged smoothly, affect the surface quality of concrete molding, and be easily corroded by the atmosphere and water environment. Construction quality and mold release effect, excellent scratch resistance and water repellency, preventing chemical reaction and physical adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040]The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0041] A semi-solid die-casting and double fluorination combined manufacturing method of a magnesium alloy building formwork of the present invention comprises the following steps:

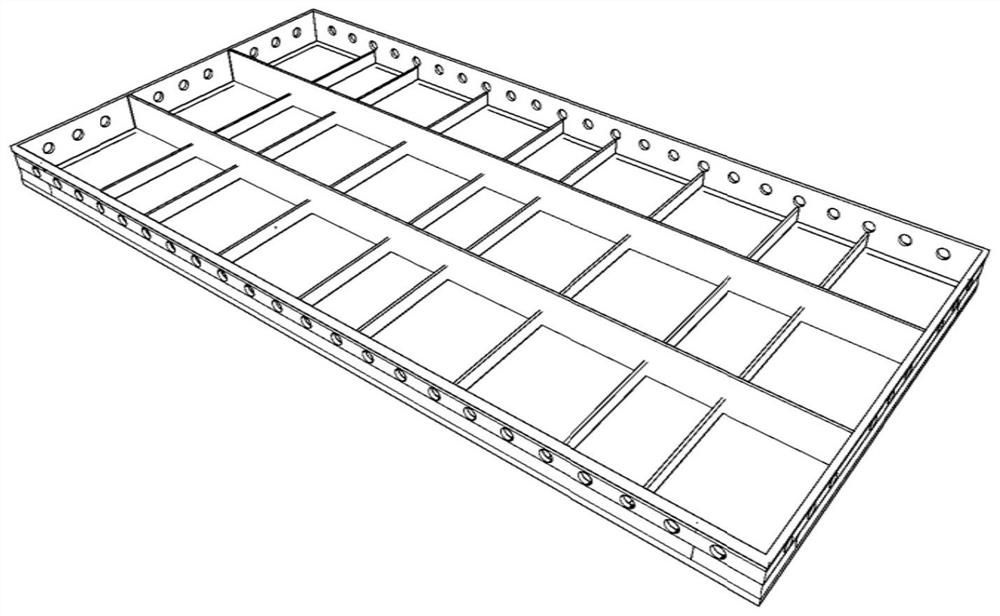

[0042] Step 1, using a semi-solid die-casting method to prepare a magnesium alloy building formwork;

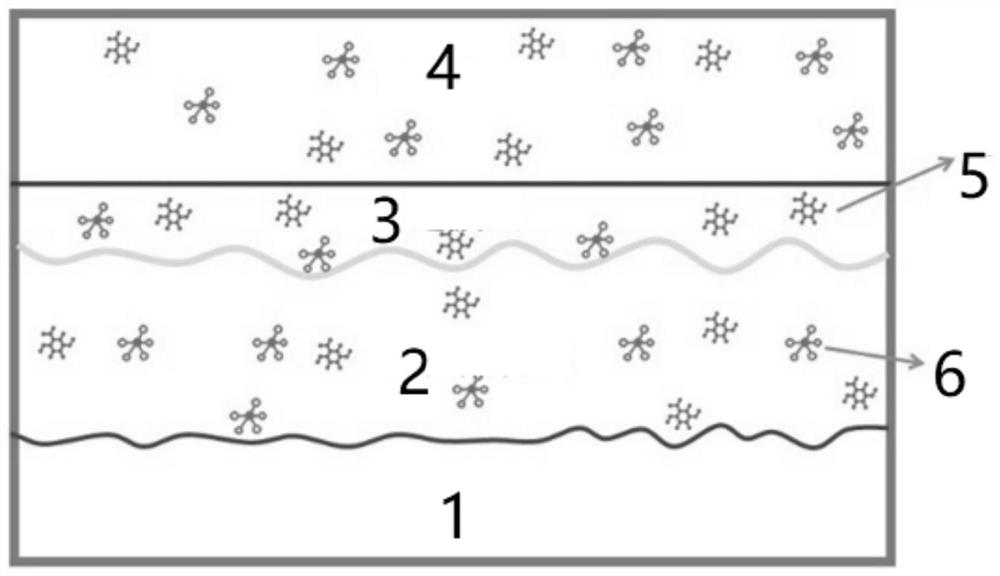

[0043] Step 2, immersing the magnesium alloy building formwork prepared in step 1 into a double fluoride treatment liquid to perform double fluorination combined treatment to obtain a double fluo...

Embodiment 1

[0046] A semi-solid die-casting and double fluorination combined manufacturing method of a magnesium alloy building formwork, comprising the following steps:

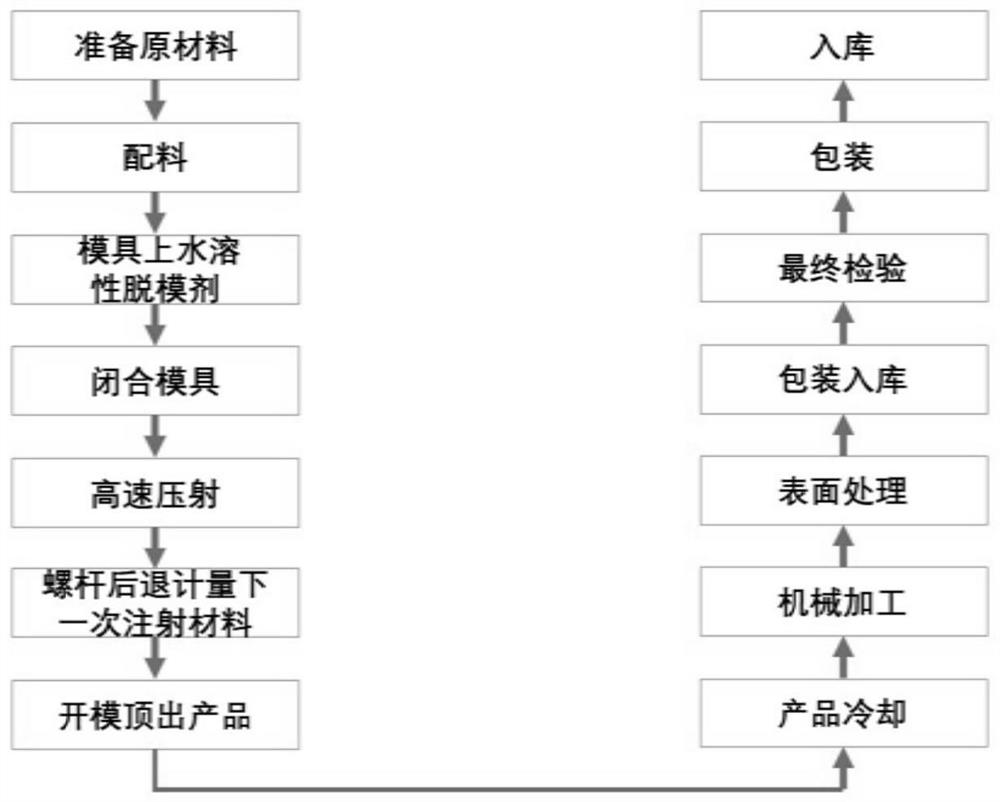

[0047] S1: Preheat the upper mold, design the mold for the template, and complete it according to the mold processing process (sample-part digital model-compilation and stamping process-mold structure design-making model-machining-grinding assembly-test mode-final inspection) Mold opening and mold testing. Install the formwork mold on the die-casting machine, connect the formwork mold with the corresponding required peripheral equipment, spray water-soluble mold release agent on the mold, and preheat the formwork mold through the mold temperature machine if there is a mold temperature requirement.

[0048] S2: Preparation and heating, prepare magnesium alloy particles with a diameter of 3-5mm and a length of about 10mm, put them into the hopper through the automatic feeding system, and forcefully transport them into the...

Embodiment 2

[0055] A semi-solid die-casting and double fluorination combined manufacturing method of a magnesium alloy building formwork, comprising the following steps:

[0056] S1: Preheat the upper mold, design the mold for the template, and complete it according to the mold processing process (sample-part digital model-compilation and stamping process-mold structure design-making model-machining-grinding assembly-test mode-final inspection) Mold opening and mold testing. Install the formwork mold on the die-casting machine, connect the formwork mold with the corresponding required peripheral equipment, spray water-soluble mold release agent on the mold, and preheat the formwork mold through the mold temperature machine if there is a mold temperature requirement.

[0057] S2: Preparation and heating, prepare magnesium alloy particles with a diameter of 3-5mm and a length of about 10mm, put them into the hopper through the automatic feeding system, and forcefully transport them into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com