A kind of method for continuously preparing methyl anthranilate

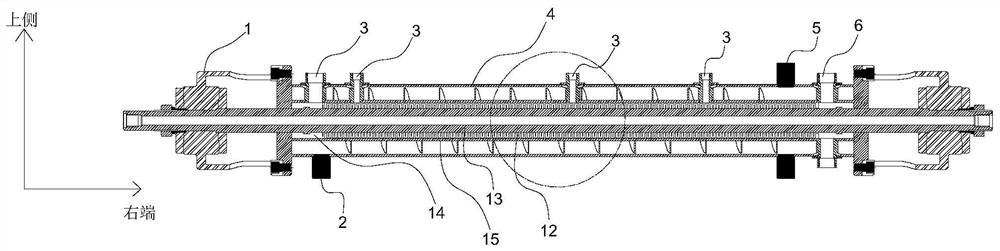

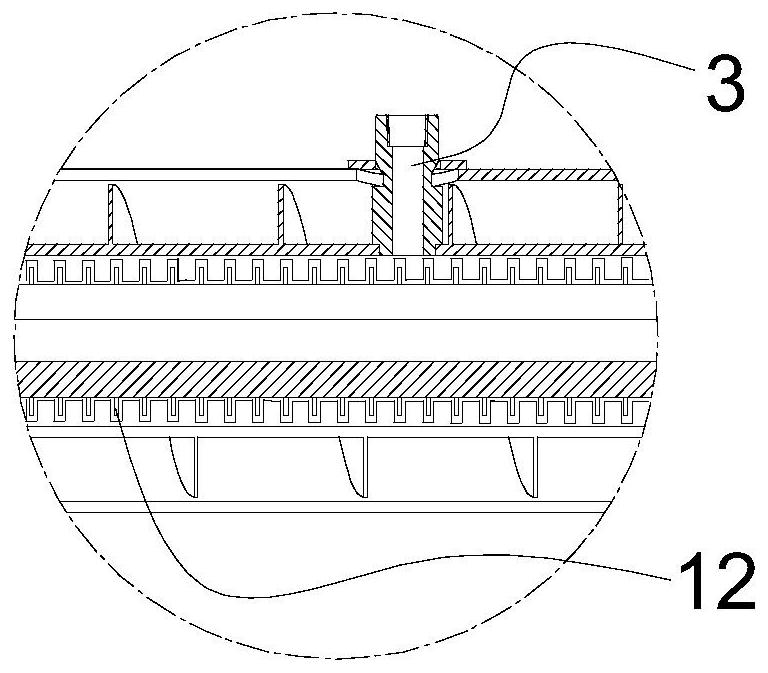

A technology of methyl aminobenzoate and sodium benzoate, applied in the field of biomedicine, can solve the problems of uneven mixing, inconsistent reaction rate, low neutralization reaction temperature, etc., so as to improve product selectivity and yield, and avoid insufficient cooling. , The effect of material mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the present embodiment, according to the steps of the above method, the continuous preparation of methyl anthranilate is carried out, and the selected concentration is 2mol / L of phthalimide, 2mol / L of sodium hydroxide, and 8mol of phthalimide. The methyl alcohol of / L, concentration are the sodium hypochlorite solution of 10%, sodium o-formamidobenzoate and methanol molar ratio are sodium o-formamidobenzoate: methyl alcohol=1:1.15, the volume ratio of sodium o-formamidobenzoate methanol solution and sodium hypochlorite solution is o Sodium formamide benzoate methanol solution: sodium hypochlorite solution=1:1.0; in step S3, the reaction temperature is controlled at -10°C, and the reaction materials stay in the reactor for 5s; in step S4, the temperature of the hydrolysis tank is controlled at 40°C.

[0049] The purity of the target product methyl anthranilate was 99.5% after the analysis of the obtained product, and the product yield was 96.2%.

Embodiment 2

[0051] In the present embodiment, according to the steps of the above method, the continuous preparation of methyl anthranilate is carried out, and the concentration is 2.5mol / L of phthalimide, 2.5mol / L of sodium hydroxide, concentration Be the methyl alcohol of 10mol / L, concentration be the sodium hypochlorite solution of 15%, sodium o-formamidobenzoate and methanol molar ratio are sodium o-formamidobenzoate: methyl alcohol=1:1.15, the volume ratio of sodium o-formamidobenzoate methanol solution and sodium hypochlorite solution It is sodium o-formamidobenzoate methanol solution: sodium hypochlorite solution=1:1.05; in step S3, the reaction temperature is controlled at -5°C, and the reaction material stays in the reactor for 8s; in step S4, the temperature of the hydrolysis tank is controlled at 45°C .

[0052] The purity of the target product methyl anthranilate was 99.7% after the analysis of the obtained product, and the product yield was 95.4%.

Embodiment 3

[0054] In the present embodiment, according to the steps of the above method, the continuous preparation of methyl anthranilate is carried out, and the selected concentration is 3 mol / L of phthalimide, 3 mol / L of sodium hydroxide, and 11 mol of phthalimide. The methyl alcohol of / L, concentration are the sodium hypochlorite solution of 20%, sodium o-formamidobenzoate and methanol molar ratio are sodium o-formamidobenzoate: methyl alcohol=1:1.15, the volume ratio of sodium o-formamidobenzoate methanol solution and sodium hypochlorite solution is o Sodium formamide benzoate methanol solution: sodium hypochlorite solution=1:1.5; in step S3, the reaction temperature is controlled at 0°C, and the reaction materials stay in the reactor for 15s; in step S4, the temperature of the hydrolysis tank is controlled at 55°C.

[0055] The purity of the target product methyl anthranilate was 99.8% after the analysis of the obtained product, and the product yield was 93.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com