Preparation method of marine antiskid arenga fiber mat

A non-slip, brown pad technology, applied in mattresses, applications, household appliances, etc., can solve the problems of lack of research and reports, and achieve the effect of protecting internal structure, removing odor, and reducing local mechanical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

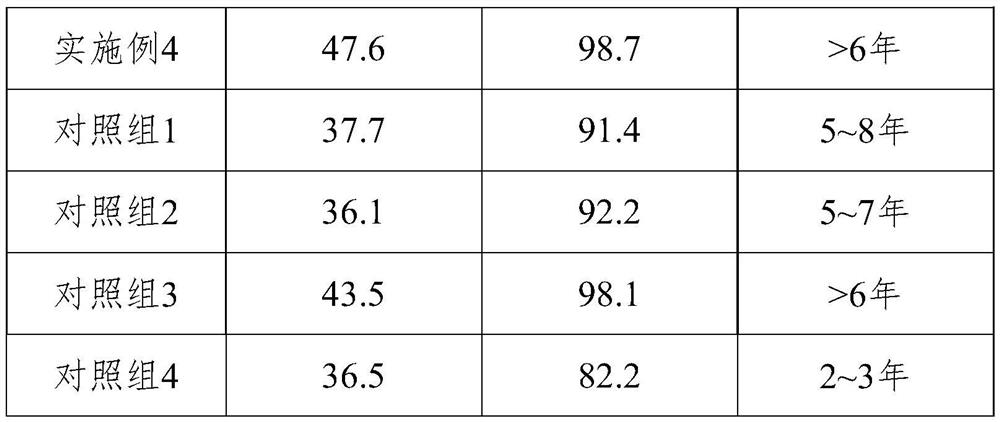

Examples

Embodiment 1

[0023] Embodiment one, a kind of preparation method of marine anti-slip mountain mat, the method comprises the steps:

[0024] (1) Spinning and sieving the dust, first cook the palm skin at 165-175°C for 16-18 hours, wash it with running water, soak it in glutinous rice water, wash it with clean water, then put it into the modified solution and heat it until Soak for 6-8 hours at 60-72°C for the second time, wash with water after soaking, dehydrate until the water content is 25-30%, keep the brown slices moist, put them in a wire drawing machine, and then air-dry them to a moisture content of ≤10%, and use a screening machine to screen out fiber filaments above 80mm;

[0025] (2) Use a rope twisting machine to twist the screened brown silk into a brown rope, and use the made brown rope as a warp and a weft according to the required width, so that the warp and weft are criss-crossed, that is, weaved into a marine non-slip Mountain cushion.

[0026] Said step (1) contains by w...

Embodiment 2

[0034] Embodiment two, a kind of preparation method of marine anti-slip mountain mat, the method comprises the following steps:

[0035] (1) Spinning and sieving the dust, first cook the palm skin at 165-175°C for 16-18 hours, wash it with running water, soak it in glutinous rice water, wash it with clean water, then put it into the modified solution and heat it until Soak for 6-8 hours at 60-72°C for the second time, wash with water after soaking, dehydrate until the water content is 25-30%, keep the brown slices moist, put them in a wire drawing machine, and then air-dry them to a moisture content of ≤10%, and use a screening machine to screen out fiber filaments above 80mm;

[0036] (2) Use a rope twisting machine to twist the screened brown silk into a brown rope, and use the made brown rope as a warp and a weft according to the required width, so that the warp and weft are criss-crossed, that is, weaved into a marine non-slip Mountain cushion.

[0037] Said step (1) con...

Embodiment 3

[0044] Embodiment three, a kind of preparation method of marine anti-slip mountain mat, the method comprises the following steps:

[0045] (1) Spinning and sieving the dust, first cook the palm skin at 165-175°C for 16-18 hours, wash it with running water, soak it in glutinous rice water, wash it with clean water, then put it into the modified solution and heat it until Soak for 6-8 hours at 60-72°C for the second time, wash with water after soaking, dehydrate until the water content is 25-30%, keep the brown slices moist, put them in a wire drawing machine, and then air-dry them to a moisture content of ≤10%, and use a screening machine to screen out fiber filaments above 80mm;

[0046] (2) Use a rope twisting machine to twist the screened brown silk into a brown rope, and use the made brown rope as a warp and a weft according to the required width, so that the warp and weft are criss-crossed, that is, weaved into a marine non-slip Mountain cushion.

[0047] Said step (1) con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com