In-situ preparation method of electrode coated with nickel-copper molybdate composite film

An in-situ preparation and composite film technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of many processes, complex processes, and the need to add binders, etc., to achieve simple processes, low investment, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

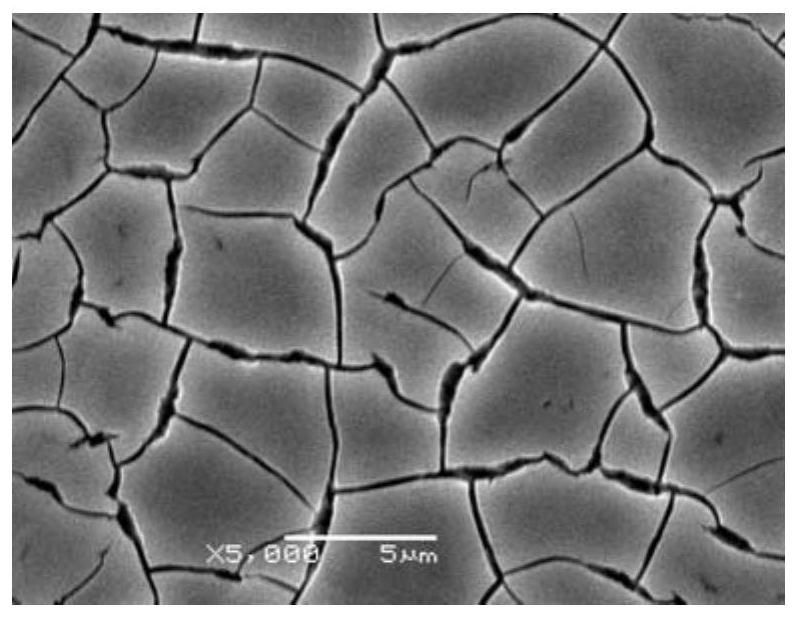

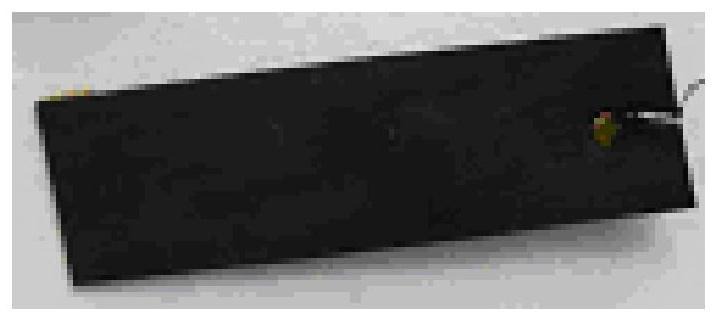

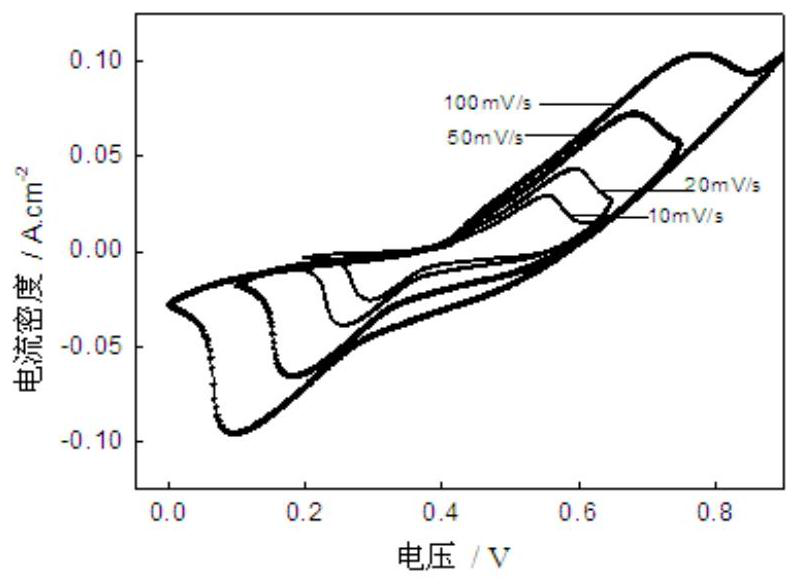

[0027] An in-situ preparation method of an electrode coated with a nickel-copper molybdate composite film according to an embodiment of the present invention, firstly, conduct a conductive substrate (which can be a pure iron sheet, a pure aluminum sheet or a pure copper sheet) with a length of 35 mm, a width of 10 mm, and a thickness of 0.2 mm. , preferably pure iron sheet) for alkaline degreasing, water washing, activation and water washing, and then electroless plating in an electroless nickel-copper-phosphorus plating solution at (78±1)°C for 120min to obtain an amorphous nickel-copper-phosphorus coating on the surface The current collector, energy spectrum analysis shows that the atomic percentage concentration ratio of nickel and copper in the amorphous nickel copper phosphorus coating is 1.1:1;

[0028] Then put the current collector into the molybdate solution prepared by 200mL / L hydrochloric acid (or sulfuric acid), 40~80g / L ammonium molybdate (or sodium molybdate) and ...

Embodiment 2

[0034] An in-situ preparation method of an electrode coated with a nickel-copper molybdate composite film according to an embodiment of the present invention, firstly, a pure iron sheet with a length of 35mm, a width of 10mm, and a thickness of 0.2mm is subjected to alkaline degreasing, water washing, activation and water washing, and then Electroless nickel-copper-phosphorus plating to obtain a current collector whose surface is covered with an amorphous nickel-copper-phosphorus coating, energy spectrum analysis shows that the atomic percentage concentration ratio of nickel and copper in the amorphous nickel-copper-phosphorus coating is 1.1:1; then the current collector is discharged Add nickel-copper molybdate composite film to the molybdate solution prepared by 200mL / L hydrochloric acid, 40g / L ammonium molybdate and 800mL / L water. The solution is heated with an oven, and the set temperature of the oven is 100°C. The reaction time is 30 minutes. After the reaction is complete...

Embodiment 3

[0037] An in-situ preparation method of an electrode coated with a nickel-copper molybdate composite film according to an embodiment of the present invention, firstly, a pure iron sheet with a length of 35mm, a width of 10mm, and a thickness of 0.2mm is subjected to alkaline degreasing, water washing, activation and water washing, and then Electroless nickel-copper-phosphorus plating to obtain a current collector whose surface is covered with an amorphous nickel-copper-phosphorus coating, energy spectrum analysis shows that the atomic percentage concentration ratio of nickel and copper in the amorphous nickel-copper-phosphorus coating is 1.1:1; then the current collector is discharged Add the molybdate nickel-copper composite film prepared in the molybdate solution prepared by 200mL / L hydrochloric acid, 40g / L ammonium molybdate and 800mL / L water, the solution is heated with a constant temperature water bath, and the temperature of the constant temperature water bath is set at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com