Composite positive electrode material and preparation method thereof, lithium battery positive electrode material and lithium battery

A composite positive electrode material and positive electrode material technology, applied in the field of lithium battery positive electrode material and lithium battery, composite positive electrode material and its preparation, can solve the problems of poor performance and uneven coating of high-nickel ternary positive electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

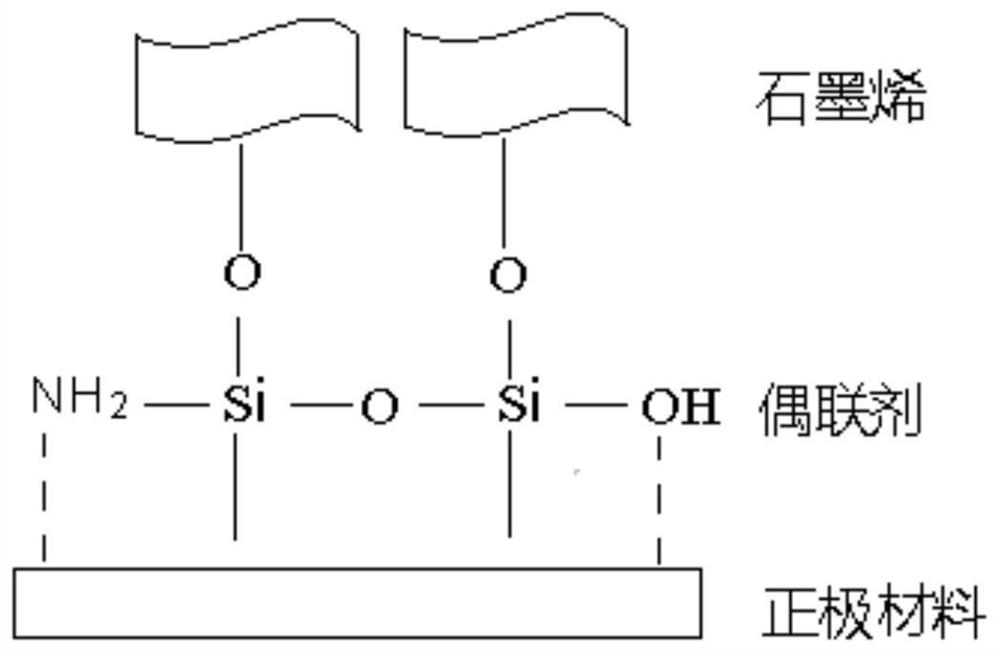

[0038] In another typical embodiment of the present application, a method for preparing the aforementioned composite positive electrode material is provided, the preparation method comprising: mixing graphene, a ternary positive electrode material and a coupling agent to obtain a composite positive electrode material.

[0039] This application simply mixes graphene, ternary positive electrode material and coupling agent, so that the coupling agent bonds graphene and ternary positive electrode material to obtain a stacked structure. The stacked structure constrains the peeling of graphene, ensures the conductivity of the composite cathode material, and realizes the uniform coating of the ternary cathode material, thereby greatly reducing the gap between graphene and the ternary cathode material, thereby shortening the The path for the diffusion and conduction of lithium ions on graphene is opened, and the internal resistance of the ternary cathode material is reduced. At the sa...

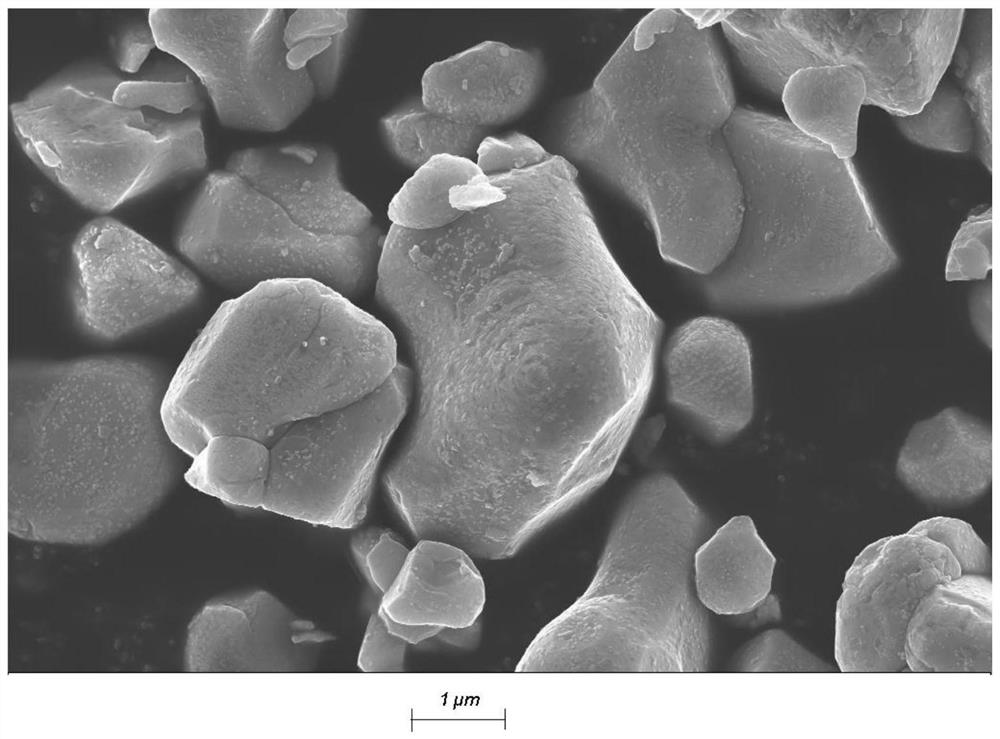

Embodiment 1

[0049] Disperse 2g of 3-layer graphene with a sheet diameter of 3 μm in NMP solvent to obtain a graphene solution with a solid content of 0.35%. 97.5g of the ternary positive electrode material is mixed with the graphene solution for the first time, and passed through a high-speed disperser in the Fully disperse and stir at a rotational speed of 1000 rpm to obtain the first mixed liquid. The first mixed liquid was mixed with 0.5g KH560 coupling agent for the second time, and the high-speed disperser was used to fully disperse and stir at the speed of 1000r / min to obtain the second mixed liquid. The second mixed solution is spray-dried (parameter conditions for spray-drying are: air inlet temperature is 199° C., wind speed is 75%, sampling peristaltic pump speed is 30%, 30s automatic needle opening, high-pressure gas flow meter 10NL / min), A dried material is obtained, and the dried material can be prepared into sheets by homogenate coating without sintering to obtain a composit...

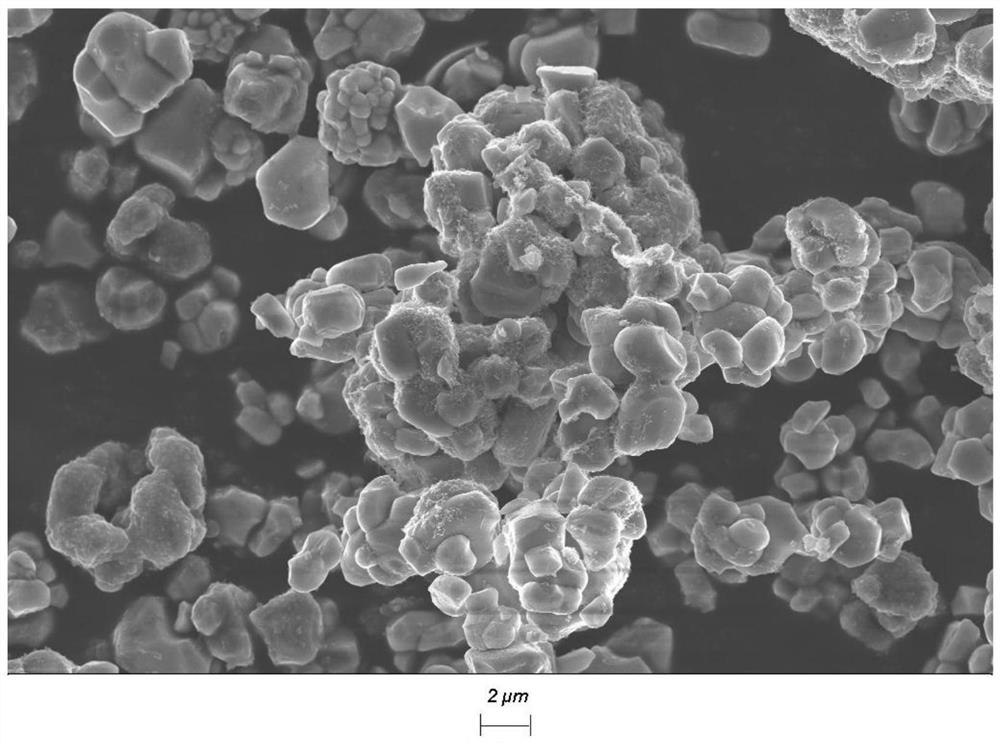

Embodiment 2

[0051] The difference between Example 2 and Example 1 is that the mass ratio of graphene (1.67g) to KH560 coupling agent (0.83g) is 2:1, and finally a composite positive electrode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com