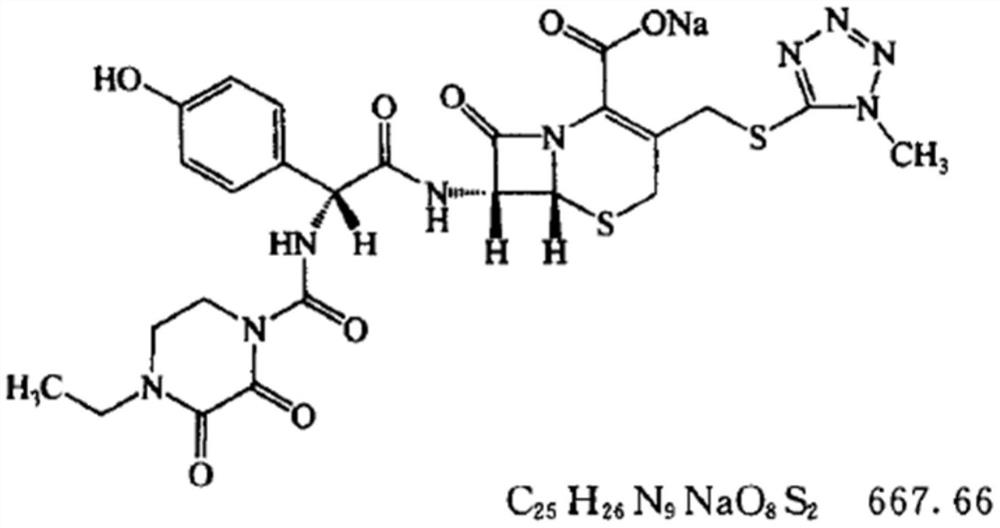

Purification method of cefoperazone sodium

A technology of cefoperazone sodium and a purification method, which is applied in the field of purification of cefoperazone sodium, can solve the problems of complex synthetic route, cumbersome preparation process, and long process, and achieve the effect of high product content, low impurity content, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

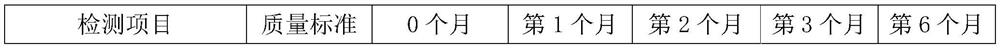

Embodiment 1

[0035] Take 80g of cefoperazone sodium and sulbactam sodium (the weight ratio of cefoperazone sodium and sulbactam sodium is 1:1, converted to 40g of cefoperazone sodium), add 160ml of purified water, control the temperature at 15°C, stir until dissolved, add 160ml of acetone, add 0.4g of activated carbon , decolorizing for 30min. Filter, wash with 5ml of purified water, combine the filtrate and washings, and set aside.

[0036] Add 800ml of acetone, 60ml of isopropanol, and 40ml of ethanol to the crystallizer; control the temperature of the crystallizer at 30-35°C, and add the above-mentioned filtrate and lotion while stirring at 400rpm / min. After the addition is completed, add sodium bicarbonate solution dropwise The pH of the solution is 6.6; after the adjustment, the temperature is controlled at 30-35°C and the crystal is grown for 180 minutes;

[0037] After the crystal growing, it took 60 minutes to cool down to 10°C, and then grow the crystal for 60 minutes. Filter, w...

Embodiment 2

[0039] Take 60g of cefoperazone sodium and sulbactam sodium (the weight ratio of cefoperazone sodium and sulbactam sodium is 2:1, converted to 40g of cefoperazone sodium), add 200ml of purified water, control the temperature at 10°C, stir until dissolved, add 200ml of acetone, add 0.4g of activated carbon , decolorizing for 30min. Filter, wash with 5ml of purified water, combine the filtrate and washings, and set aside.

[0040] Add 720ml of acetone, 20ml of isopropanol, and 20ml of ethanol to the crystallizer; control the temperature of the crystallizer at 30-35°C, and add the above-mentioned filtrate and lotion while stirring at 500rpm / min. After the addition is complete, add sodium bicarbonate solution dropwise The pH of the solution is 6.5; after the adjustment, the temperature is controlled at 30-35°C to grow the crystal for 210 minutes;

[0041] After the crystal growth is completed, it takes 90 minutes to cool down to 8°C, and then grow the crystal for 60 minutes. Fil...

Embodiment 3

[0043] Take 60kg of cefoperazone sodium and sulbactam sodium (the weight ratio of cefoperazone sodium and sulbactam sodium is 1:1, the conversion of cefoperazone sodium is 30kg), add 150L of purified water, control the temperature at 10°C, stir until dissolved, add 150L of acetone, add 0.3kg of activated carbon , decolorizing for 30min. Filter, wash with 5L of purified water, combine the filtrate and washings, and set aside.

[0044] Add 600L of acetone, 30L of isopropanol, and 30L of ethanol to the crystallizer; control the temperature of the crystallizer at 30-35°C, and add the above-mentioned filtrate and lotion while stirring at 450rpm / min. After the addition is complete, add sodium bicarbonate solution dropwise Liquid pH to 6.5; after adjustment, temperature control 30-35°C to grow crystal for 200min;

[0045] After the crystal growing, it took 180 minutes to cool down to 8°C, and then grow the crystal for 60 minutes. Filter, wash with 300L of 9:1 acetone-water mixture,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com