Manufacturing method of low-cost echo wall microcavity laser based on erbium-doped microspheres

A production method and whispering gallery technology, which is applied in the field of production of low-cost whispering gallery microcavity lasers based on erbium-doped microspheres, can solve problems such as high cost and potential safety hazards, and achieve low cost, lower requirements, and low threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

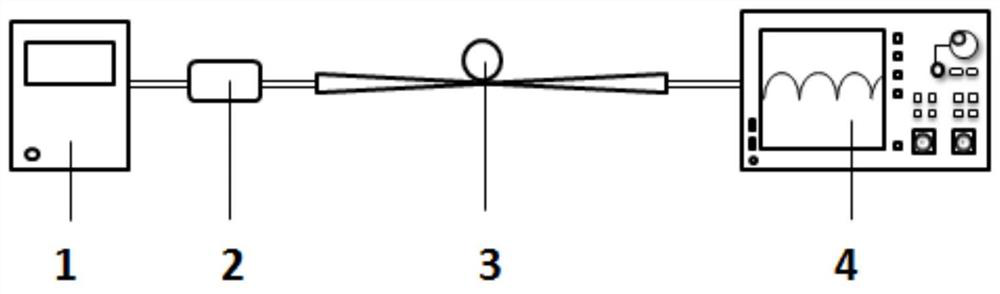

[0013] figure 1 Shown is a schematic diagram of an implementation and application system of the present invention, including a 980nm pump light source 1 , an optical isolator 2 , a microcavity structure 3 , and a spectrum analyzer 4 . The connection method is: the 980nm pumping light source 1 is connected to one end of the optical isolator 2, the other end of the optical isolator 2 is connected to one end of the microcavity structure 3, and the other end of the microcavity structure 3 is connected to one end of the spectrum analyzer 4 .

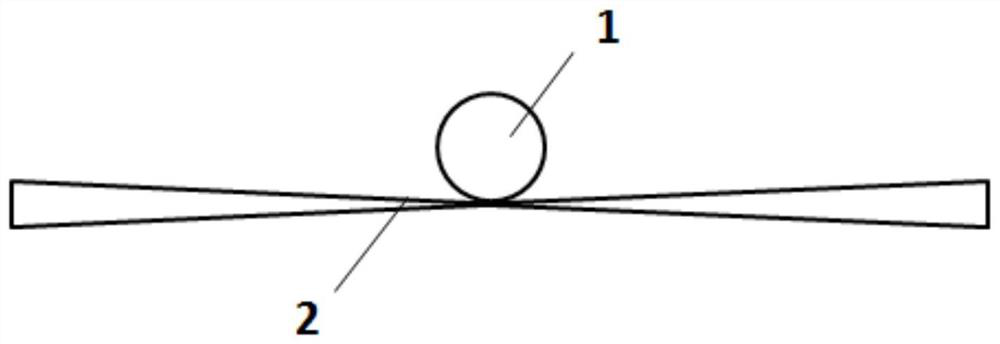

[0014] figure 2 Shown is a schematic diagram of the structure of the microcavity of the present invention, and the distance between the tapered optical fiber 2 and the erbium-doped microsphere 1 should not exceed 30 nm.

[0015] The manufacturing method and steps of the microcavity structure are as follows: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com