Chitosan modified guanidine salt polymer and preparation method thereof, modified waterborne polyurethane and preparation method thereof, and modified waterborne polyurethane coating

A technology of chitosan modification and guanidinium salt polymer, which is applied in the field of antibacterial polyurethane, which can solve the problems of poor antibacterial type and poor performance of resin paint film, so as to reduce viscosity, ensure long-term durability and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

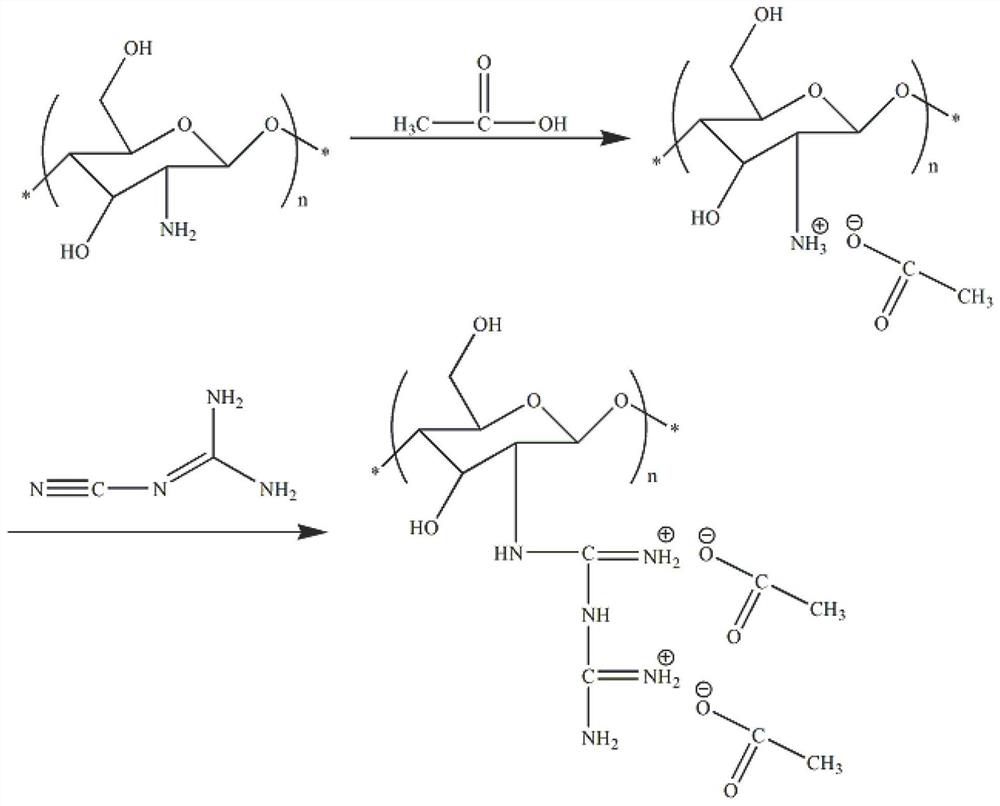

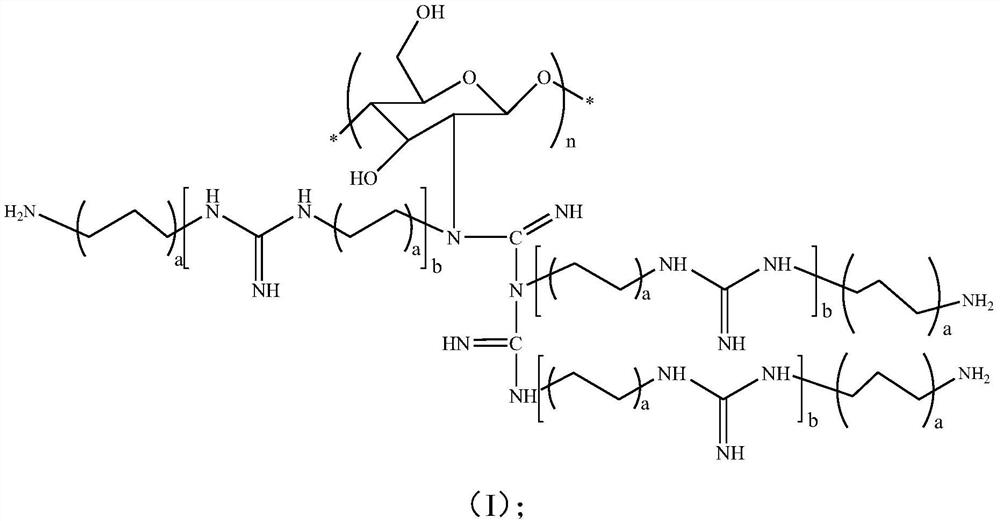

[0080] The invention provides a kind of preparation method of chitosan modified guanidinium polymer, comprising the following steps:

[0081] 1) after mixing chitosan and acid, chitosan salt compounds are obtained;

[0082] 2) After the chitosan salt compound, dicyandiamide and water obtained in the above steps are subjected to a nucleophilic addition reaction, the chitosan biguanide salt compound is obtained;

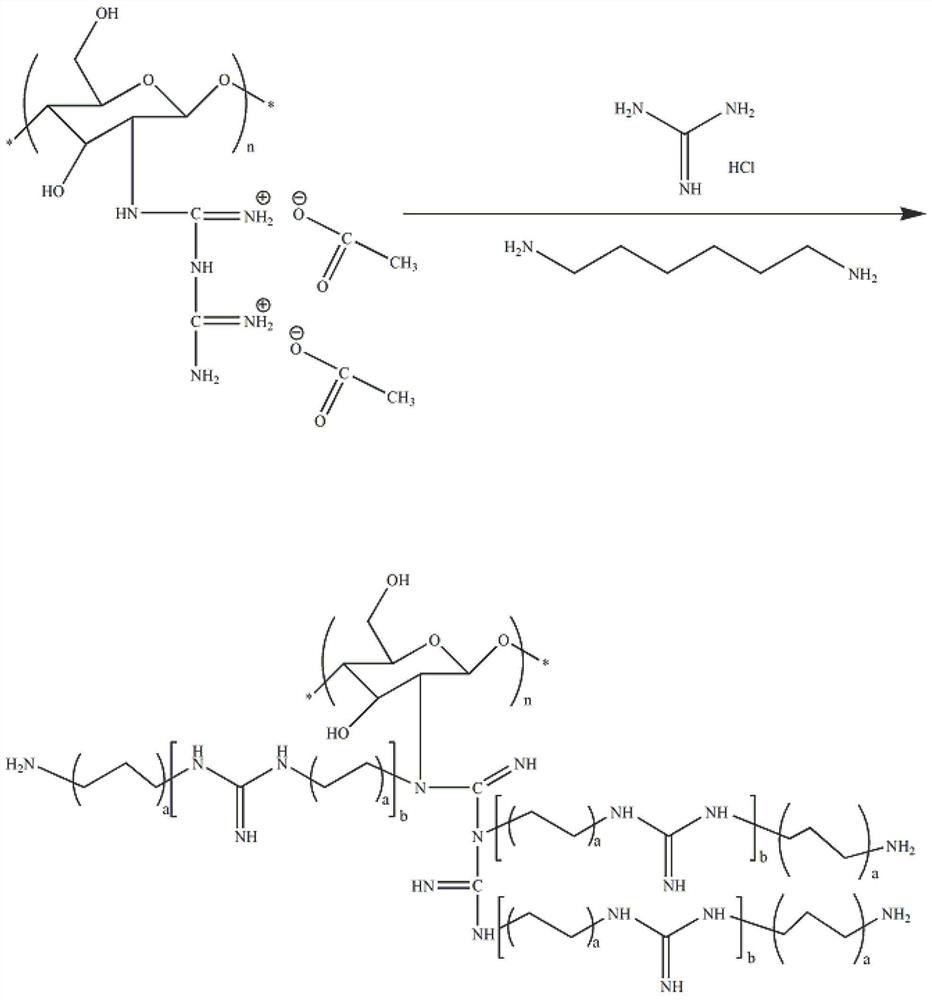

[0083] 3) After the chitosan biguanide salt compound obtained in the above steps, the diamine monomer, guanidine hydrochloride and water are polymerized, the chitosan is modified into the guanidine salt polymer.

[0084] The present invention is to the composition, structure and parameter of the chitosan modified guanidinium salt polymer in the above-mentioned preparation method, and corresponding preferred principle, and the composition, structure and parameter in the aforementioned chitosan modified guanidinium salt polymer, and Corresponding optimization principles...

Embodiment 1

[0180] The first step, chitosan biguanide acetate preparation:

[0181] Dissolve 1-5g of chitosan in 50ml of acetic acid, stir for 0.5 hours, add to 30ml of absolute ethanol, place at 2°C for 24 hours, filter with suction, then wash with ethanol three times, when the filtrate pH=6.5, dry to obtain Chitosan acetate powder. Add the chitosan acetate powder into the reaction flask, then add 20g of deionized water and 1.5g of dicyandiamide, react at 90°C for 5 hours, cool to room temperature, and add the reaction solution into 50g of absolute ethanol , placed at 2° C. for 24 hours, filtered, washed with absolute ethanol until the filtrate pH = 6.5, and dried in a vacuum oven at 40° C. for 24 hours to obtain chitosan biguanide acetate powder.

[0182] The chitosan biguanide acetate prepared in Example 1 of the present invention was carried out infrared spectroscopic analysis.

[0183] FTIR (KBr tablet): 1602cm -1 The spectral peak appears, which is the amino bending vibration abs...

Embodiment 2

[0189] The first step, chitosan biguanide acetate preparation:

[0190] Dissolve 5g of chitosan in 200ml of acetic acid, stir for 0.5 hours, add to 180ml of absolute ethanol, place at 8°C for 48 hours, filter with suction, then wash with ethanol three times, when the filtrate pH=6.5, dry to obtain chitosan Sugar Acetate Powder. Add the chitosan acetate powder into the reaction flask, then add 50g of deionized water and 9.1g of dicyandiamide, react at 130°C for 2 hours, cool to room temperature, and add the reaction solution to 220g of absolute ethanol place at 8° C. for 48 hours, filter, wash the filtrate with absolute ethanol until pH = 6.5, and dry in a vacuum oven at 40° C. for 48 hours to obtain chitosan biguanide acetate powder.

[0191] The second step: chitosan polyguanidine salt preparation:

[0192] Add 19.2g of 1,6-hexanediamine and 17.6g of guanidine hydrochloride to the chitosan biguanide acetate obtained in the first step, then add 210g of deionized water, raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com