A panel light glue

A lamp glue and panel technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of optical color rendering interference, high cost, big smell and unenvironmental protection, and achieve good economic benefits and social benefits. Benefit, excellent product stability, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

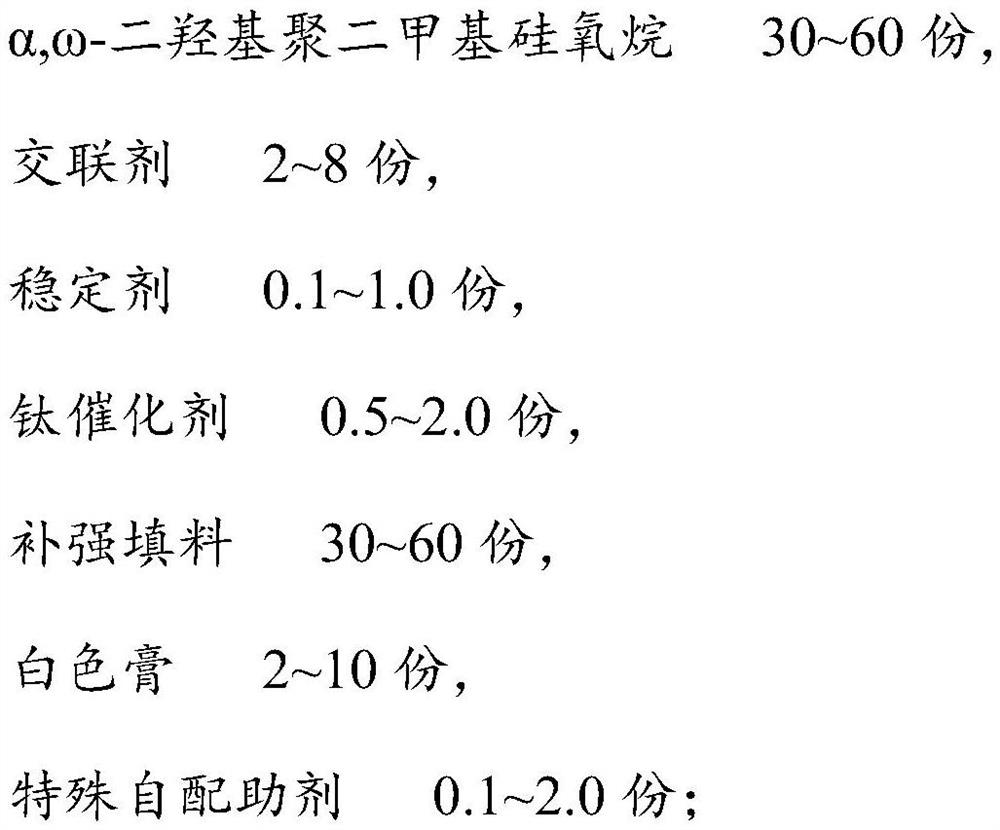

Method used

Image

Examples

Embodiment 1

[0039] Add 50 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s, 50 parts of nano-calcium powder, and 2.5 parts of white paste of titanium dioxide series to the planetary mixer at room temperature, and turn it on to heat up. Set the oil temperature and material temperature to 130°C. When the material temperature rises to 90°C, turn on the vacuum and continue to remove water for 1.5 to 2.0 hours. Then turn off the heating and vacuum and cool to room temperature. Add 2 parts of methyltrimethoxysilane and 0.7 parts of vinyl Stir trimethoxysilane and 1 part of Ti726 catalyst under vacuum for 25 minutes, add 0.3 parts of hindered amine light stabilizer and 1.25 parts of special self-preparing additives and stir under vacuum for 25 minutes to discharge. Among them, the special self-preparation additive is obtained by uniformly mixing the imino group-containing organosilicon compound with the secondary amino coupling agent and the α-amino coupling agent at a r...

Embodiment 2

[0041] Add 30 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s, 60 parts of nano-calcium powder, and 2.5 parts of white paste of titanium dioxide series to the planetary mixer at room temperature, and turn it on to heat up. Set the oil temperature and material temperature to 130°C. When the material temperature rises to 90°C, turn on the vacuum and continue to remove water for 1.5 to 2.0 hours. Then turn off the heating and vacuum and cool to room temperature. Add 2 parts of methyltrimethoxysilane and 0.7 parts of acetoacetic acid Ethyl ester and 1 part of n-butyl titanate catalyst were stirred under vacuum for 25 minutes, then 0.3 part of hindered amine light stabilizer and 0.1 part of special self-prepared additive were added and stirred under vacuum for 25 minutes to discharge. Among them, the special self-preparation additive is obtained by uniformly mixing the imino group-containing organosilicon compound with the secondary amino coupling agent an...

Embodiment 3

[0043] Add 60 parts of α,ω-dihydroxypolydimethylsiloxane with a viscosity of 20000mPa·s, 30 parts of nano-calcium powder, and 2.5 parts of white paste of titanium dioxide series to the planetary mixer at room temperature, and turn it on to heat up. Set the oil temperature and material temperature to 130°C. When the material temperature rises to 90°C, turn on the vacuum and continue to remove water for 1.5 to 2.0 hours. Then turn off the heating and vacuum and cool to room temperature. Add 8 parts of methyltrimethoxysilane and 0.7 parts of acetoacetic acid Ethyl ester and 2 parts of n-butyl titanate catalyst were stirred under vacuum for 25 minutes, and then 0.3 parts of hindered amine light stabilizer and 0.1 part of special self-prepared additive were added and stirred under vacuum for 25 minutes to discharge. Among them, the special self-preparation additive is obtained by uniformly mixing the imino group-containing organosilicon compound with the secondary amino coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com