Stainless steel passivation solution and method for improving corrosion resistance of stainless steel wiredrawing floor drain

A technology of stainless steel and passivation solution, applied in the direction of metal material coating process, etc., can solve the problems of influence, inapplicability of passivation solution, inability to meet the corrosion resistance requirements of stainless steel wire drawing floor drain, etc. Corrosion effect and protection life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

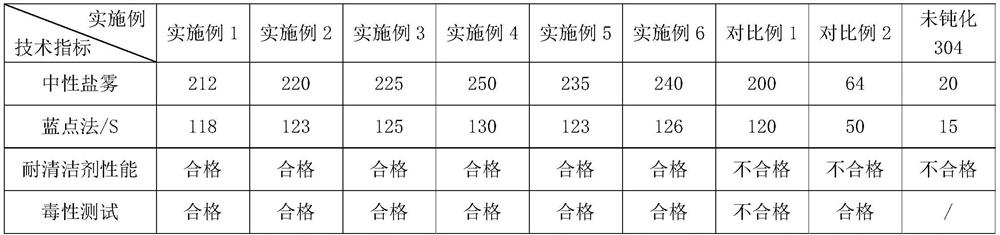

Examples

Embodiment 1

[0035] Pre-treatment of stainless steel wire drawing floor drain: use ultrasonic cleaning machine to add cleaning agent for cleaning. ; Make a uniform water film on the surface of the stainless steel wire drawing floor drain, which can meet the passivation requirements.

[0036] Passivation: Soak the cleaned stainless steel wire drawing floor drain in the prepared passivation solution for pickling and passivation. The passivation temperature is 25°C and the passivation time is 15 minutes;

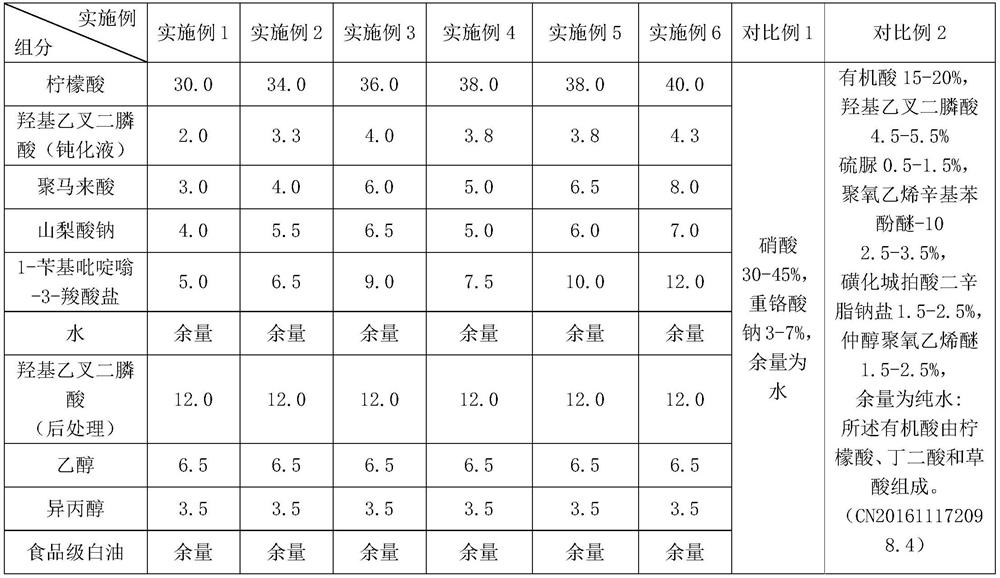

[0037] The passivation solution is 30.0% of citric acid, 2.0% of hydroxyethylidene diphosphonic acid, 3.0% of polymaleic acid, 4.0% of sodium sorbate, 5.0% of 1-benzylpyridinium-3-carboxylate, and the balance is water ;

[0038] Cleaning: Use 1 channel of tap water and 1 channel of deionized water for soaking and cleaning in flowing water, and the cleaning time is 2.5 minutes;

[0039] Drying 1: Dry with hot air to ensure no water stains on the surface;

[0040] Post-treatment: soak the dr...

Embodiment 2~6

[0044] The components of the passivation solution are shown in Table 1, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com