Gas diffusion layer as well as preparation method and application thereof

A gas diffusion layer and diffusion layer technology, applied in electrical components, fuel cells, electrochemical generators, etc., can solve the problems of poor mass transfer capacity and air permeability of ultra-thin carbon fiber paper, and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

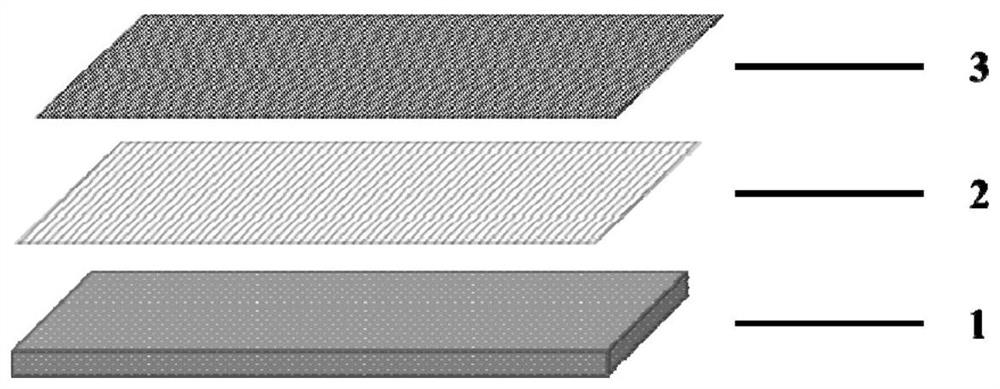

[0112] A kind of preparation method of gas diffusion layer comprises the steps:

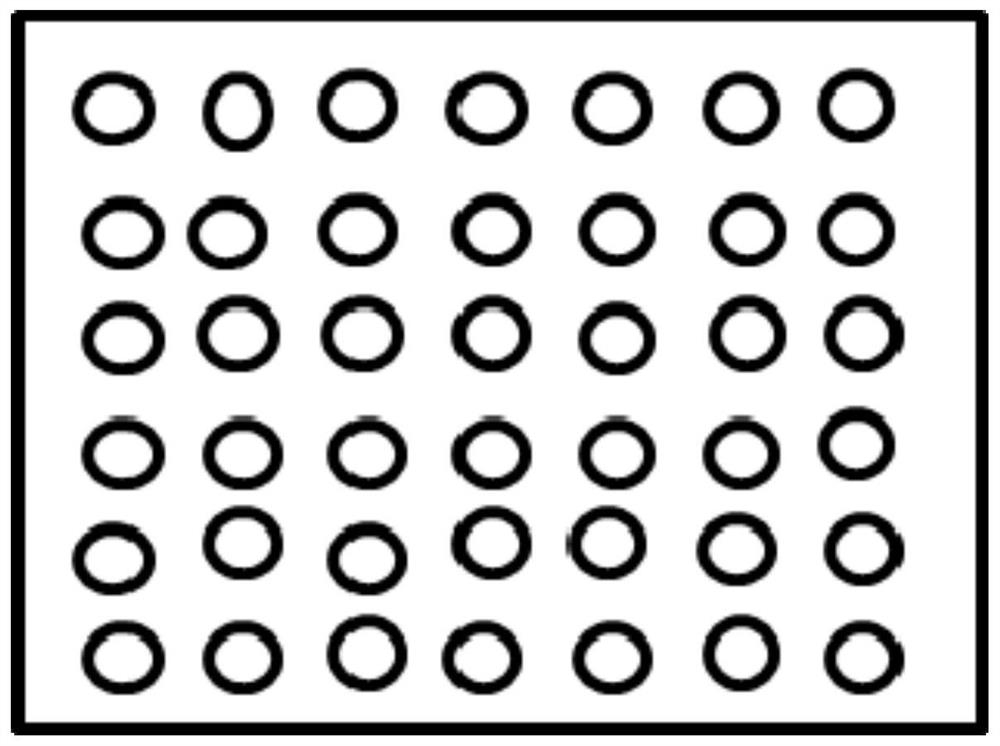

[0113] (1) Preparation of the support layer: Laser-drill the carbon nanotube film with a thickness of 20 μm, and then use 3mol / L sulfuric acid to soak at 80°C for 60 minutes to remove the cations in the carbon nanotube film, and obtain the support layer structure Schematic such as figure 1 As shown, it can be seen from the figure that the holes in the support layer are circular holes with a diameter of 35 μm and are regularly arranged, and the porosity of the support layer is 80%;

[0114] (2) Preparation of composite carbon material diffusion layer:

[0115] (a) ultrasonically dispersing PP carbon fibers in pure water to obtain a carbon fiber dispersion;

[0116] (b) Soak single-walled carbon nanotubes in 3mol / L sulfuric acid at 80°C for 8h, centrifuge them with ethanol and pure water, and then ultrasonically mix them with sodium dodecylbenzenesulfonate and pure water in a cell disruptor 3h, ...

Embodiment 2

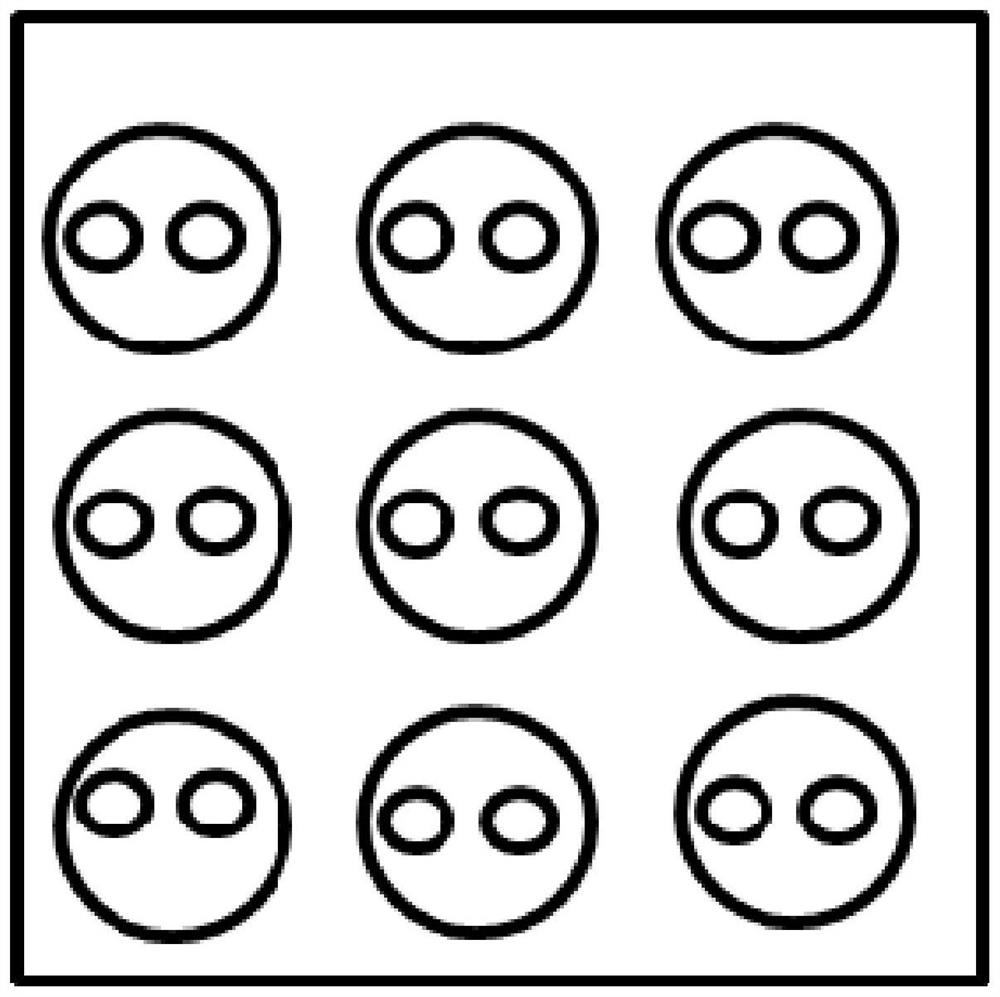

[0122] The difference from Example 1 is that in step (1) the carbon nanotube film is laser drilled, and the obtained support layer structure schematic diagram is as follows figure 2 As shown, it can be seen from the figure that the holes in the support layer are a first circular hole with a diameter of 100 μm and two second circular holes with a diameter of 40 μm distributed in the first circular hole, wherein the first circular hole The second circular hole is a permeable hole. The porosity of the support layer is 82%.

Embodiment 3

[0124] The difference from Example 1 is that the diameter of the circular hole in the support layer in step (1) is 30 μm, and the porosity of the support layer is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com