Composite fabric of various fiber fabrics and production method of composite fabric

A composite fabric and production method technology, applied in the direction of cellulose plastic material layered products, fiber treatment, animal fiber, etc., can solve the problems of environmental protection, such as imperfection, harmfulness, skin irritation, etc., to achieve lasting moisturizing skin, Improves skin elasticity and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

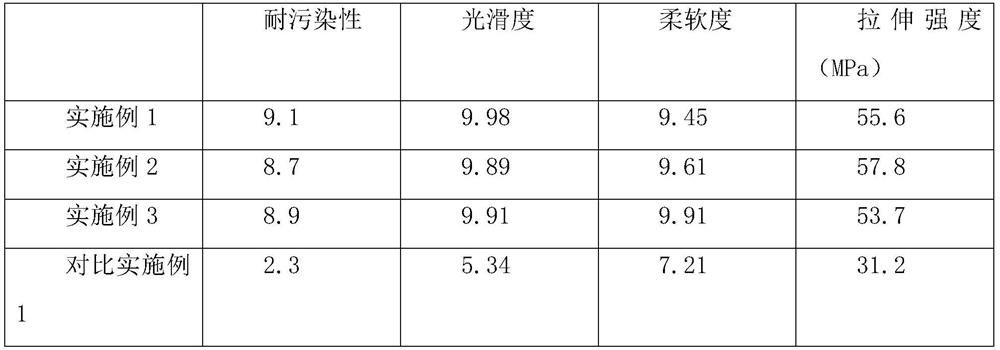

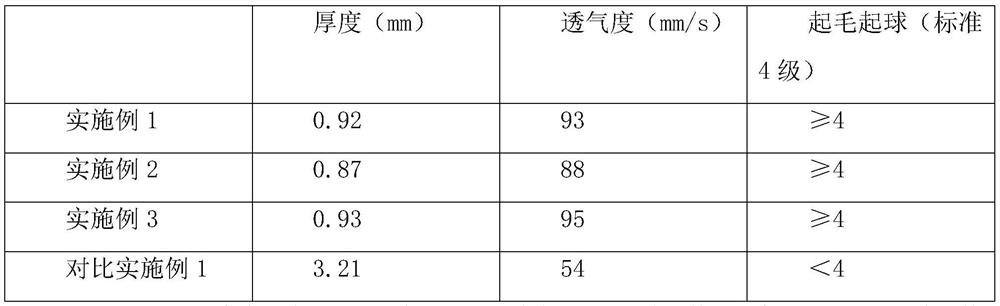

Examples

preparation example Construction

[0037] Furthermore, the preparation method of the natural combination liquid is as follows: a certain amount of strawberry extract, horse chestnut extract, lovage extract, horse chestnut extract, elderberry extract, arnica extract , pomegranate fruit extract and water lily extract are added to the blending tank in sequence, the temperature is controlled at 40-50°C, the rotation speed is 500-800r / min, and the natural combination liquid is obtained by mixing evenly for 20-30min;

[0038] The extraction method of each plant extract in the above-mentioned natural combination liquid can adopt the cooking extraction method, and its steps are as follows:

[0039]Wash fresh plant raw materials with water, add water to soak for 10-15 minutes, then boil on low heat, turn off the heat before the water is opened, cover and steam for 10-15 minutes, do not open the lid halfway;

[0040] After cooling, move it into another container, cover it with plastic wrap, and place it at room temperatu...

Embodiment 1

[0051] A composite fabric of multiple fiber fabrics, the composite fabric is composed of a first fiber surface layer, a second fiber core layer, a third fiber inner layer and an adhesive;

[0052] The first fiber surface layer is made up of spandex fibers of 50 parts by weight, polyester fibers of 10 parts by weight and viscose fibers of 15 parts;

[0053] The second fiber core layer is made up of the cotton fiber of 40 parts by weight, the bamboo fiber of 20 parts by weight and the nursing solution of 15 parts by weight;

[0054] The ingredients of the care solution are composed by weight: 4 parts of antifungal agent, 3 parts of deodorant, 1 part of flame retardant and 5 parts of plant essential oil;

[0055] The third fiber inner layer is formed by interweaving warp, weft and wool yarn, the weft is a skin care fiber processed by 12 parts by weight of natural combination liquid, the warp is nanofiber, and the wool is protein fiber;

[0056] The ingredients of the natural com...

Embodiment 2

[0058] A composite fabric of multiple fiber fabrics, the composite fabric is composed of a first fiber surface layer, a second fiber core layer, a third fiber inner layer and an adhesive;

[0059] The first fiber surface layer is made up of spandex fibers of 60 parts by weight, polyester fibers of 20 parts by weight and viscose fibers of 25 parts;

[0060] The second fiber core layer is made up of the cotton fiber of 50 parts by weight, the bamboo fiber of 30 parts by weight and the nursing solution of 25 parts by weight;

[0061] The composition of the care solution is composed by weight: 8 parts of antifungal agent, 5 parts of deodorant, 3 parts of flame retardant and 10 parts of plant essential oil;

[0062] The third fiber inner layer is formed by interweaving warp, weft and wool yarn, the weft is a skin care fiber processed through 20 parts by weight of natural combination liquid, the warp is nanofiber, and the wool is protein fiber;

[0063] The ingredients of the natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com