Transparent high-barrier food packaging composite film and preparation method thereof

A food packaging, high-barrier technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of polyvinyl alcohol-coated film barrier property decline, unsatisfactory barrier performance, and poor barrier property. Easy and complete cross-linking and curing, excellent oxygen barrier properties, and improved barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

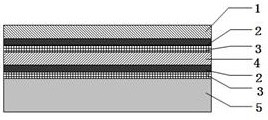

[0044] A transparent high-barrier food packaging composite film, characterized in that it includes a first film layer 1, a coating layer 2, an adhesive layer 3, a second film layer 4, a coating layer 2, an adhesive layer 3, and a third film layer arranged in sequence. Film layer 5; the coating layer is a water-based polyurethane-nano-silicon mixed coating layer.

[0045] Further, the first film layer is a polyethylene terephthalate film layer.

[0046] Further, the adhesive layer is an ester-soluble polyurethane adhesive layer.

[0047] Further, the second film layer is a polyamide film layer.

[0048] Further, the third film layer is a polypropylene film layer.

[0049] Further, the polypropylene film layer is a cooking grade cast polypropylene film layer.

Embodiment 2

[0051] This embodiment provides a method for preparing a transparent high-barrier food packaging composite film in Embodiment 1, comprising the following steps:

[0052] In the first step, add 7.5kg of nano-silicon to 32.3kg of deionized water, stir for 15 minutes, then add 9.7kg of water-based polyurethane, stir for 15 minutes, then add 0.5kg of water-dispersed isocyanate curing agent, stir After 20 minutes, ultrasonically disperse for 10 minutes, and then filter with a 300-mesh filter to obtain a water-based polyurethane-nano-silicon mixed coating layer liquid.

[0053] In the second step, the coating is carried out on the dry compound machine, and the coating amount is controlled at 1.5 grams per square meter. The three-level temperature setting of the drying tunnel of the dry compound machine is 75°C, 85°C, and 100°C in sequence, and the machine speed is set to At 80 revolutions per minute, the above-mentioned water-based polyurethane-nano-silicon mixed coating layer liqui...

Embodiment 3

[0058] This embodiment provides a method for preparing a transparent high-barrier food packaging composite film in Embodiment 1, comprising the following steps:

[0059] In the first step, add 10.0kg of nano-silicon to 29.8kg of deionized water, stir for 15 minutes, then add 9.7kg of water-based polyurethane, stir for 15 minutes, then add 0.5kg of water-dispersed isocyanate curing agent, stir After 20 minutes, ultrasonically disperse for 10 minutes, and then filter with a 300-mesh filter to obtain a water-based polyurethane-nano-silicon mixed coating layer liquid.

[0060] In the second step, the coating is carried out on the dry compound machine, and the coating amount is controlled at 1.5 grams per square meter. The three-level temperature setting of the drying tunnel of the dry compound machine is 75°C, 85°C, and 100°C in sequence, and the machine speed is set to At 80 revolutions per minute, the above-mentioned water-based polyurethane-nano-silicon mixed coating layer liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com