A kind of method for preparing carbon black

A technology of carbon black and carbon, which is applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, inorganic pigment treatment, etc., can solve the waste of resources, can not fundamentally eliminate the toxicity and corrosion hazards of aluminum electrolysis waste cathode materials, etc. Problems, achieve the effect of reducing energy consumption, saving non-renewable resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

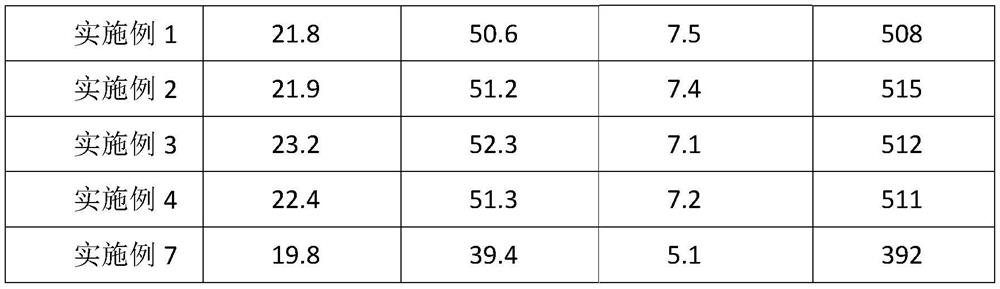

Embodiment 1

[0050] Take 1kg of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, the main element content is (wt.%): C 70.9, Al8.23, O 9.55, F 5.38, Na 2.57, Fe 1.21, crushed to -200 mesh, accounting for 90% , add 30 L of mixed solution of 8 mol / L nitric acid and 2 mol / L hydrogen peroxide, and leaching for 10 h under the conditions of leaching temperature of 80°C and stirring speed of 200 r / min.

[0051]After acid leaching, wash to neutral drying to obtain carbon powder, mix carbon powder and NaOH evenly at a mass ratio of 1:1.7, add 20g of deionized water in turn, stand for immersion for 4 hours, and after standing for immersion, the pulp is evaporated to dryness and dehydrated. Put it in a thermal cracking furnace at 800°C for pyrolysis and carbonization; then transfer it to an activation furnace for activation and hole expansion, and the steam temperature is 600°C to obtain alkali-melting carbon black; after cooling, wash with water to weak alkalinity...

Embodiment example 2

[0054] Take 1kg of carbon slag from a waste battery cathode in a domestic factory, the main element content is (wt.%): C 87.11, Al 2.24, O3.50, Zr 1.64, Ca 1.60, Fe 0.42, P 1.44, S 0.09, Si 0.38, Ti 0.34, crushed to -200 mesh and accounted for 90%, add 25L of a mixed solution of 6mol / L nitric acid and 2mol / L hydrogen peroxide, and leach for 9 hours at a leaching temperature of 75°C and a stirring speed of 180r / min.

[0055] After acid leaching, wash to neutral drying to obtain carbon powder, mix carbon powder and NaOH evenly at a mass ratio of 1:1.5, add 20g of deionized water in turn, stand for immersion for 4 hours, and after standing for immersion, the pulp is evaporated to dryness and dehydrated. Put it in a thermal cracking furnace at 700°C for cracking and carbonization; then transfer it to an activation furnace for activation and hole expansion, and the water vapor temperature is 550°C to obtain alkali-melting carbon black; after cooling, wash with water to weak alkalini...

Embodiment example 3

[0058] Take 1 kg of waste activated carbon from a domestic factory, the carbon element content is 94wt.%, and it is crushed to -200 mesh to account for 90%. Add 10L of a mixed solution of 6mol / L nitric acid and 1mol / L hydrogen peroxide. The leaching temperature is 60°C. Under the condition of stirring rate of 150r / min, leaching was carried out for 8h.

[0059] After acid leaching, wash to neutral drying to obtain carbon powder, mix carbon powder and NaOH evenly at a mass ratio of 1:1.5, add 20g of deionized water in turn, stand for immersion for 4 hours, and after standing for immersion, the pulp is evaporated to dryness and dehydrated. Put it in a thermal cracking furnace at 600°C for pyrolysis and carbonization; then transfer it to an activation furnace for activation and hole expansion, and the water vapor temperature is 550°C to obtain alkali-melting carbon black; after cooling, wash with water to weak alkalinity, and dry to obtain powder carbon black, the obtained carbon ...

PUM

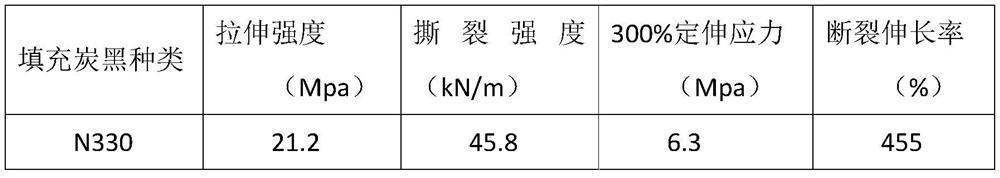

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com