A kind of high-durability water-based polyurethane outdoor wood paint and preparation method thereof

A durable water-based, polyurethane technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

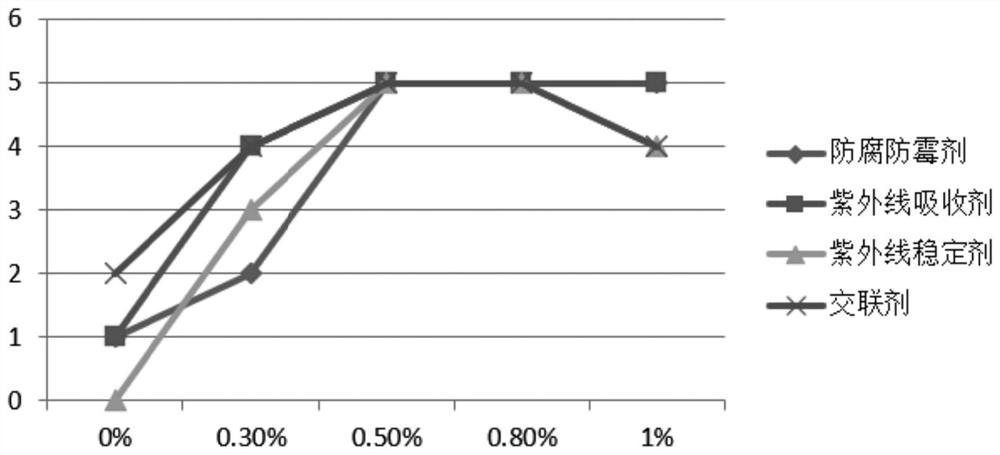

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of mercapto-terminated aliphatic waterborne polyurethane

[0026] This embodiment sets 5 groups of treatment groups, labeled as treatment 1, treatment 2, treatment 3, treatment 4 and treatment 5 to prepare mercapto-terminated modified aliphatic water-based polyurethane respectively. At the same time, this embodiment also has a control treatment to prepare fat Aquatic polyurethane, the operation method of each treatment group is as follows.

[0027] 1.1 Processing 1

[0028] Step 1: Add 21.11g of polyether diol and 19.03g of isophorone diisocyanate in a four-necked flask equipped with a mechanical stirrer, a thermometer and a reflux condenser, stir evenly, and then add 0.1g of tributyl tin hydride;

[0029] Step 2: heating the mixed solution obtained in the step 1 to 70°C and keeping it warm for 5 hours;

[0030] Step 3: Add dimethylolpropionic acid (3.02g) / N-methylpyrrolidone (7g) solution to the mixed solution treated in step 2, so that the temperatur...

Embodiment 2

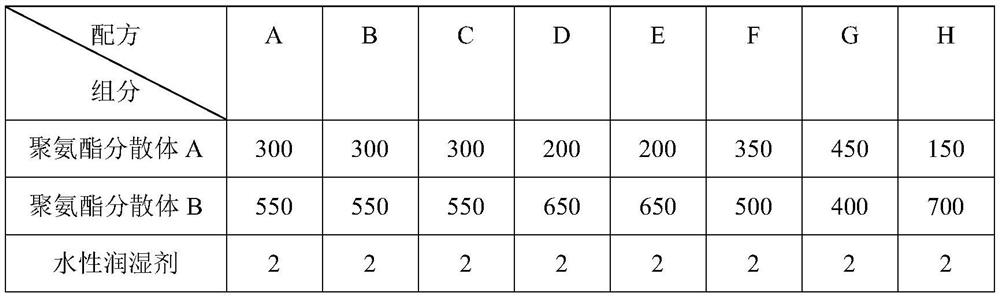

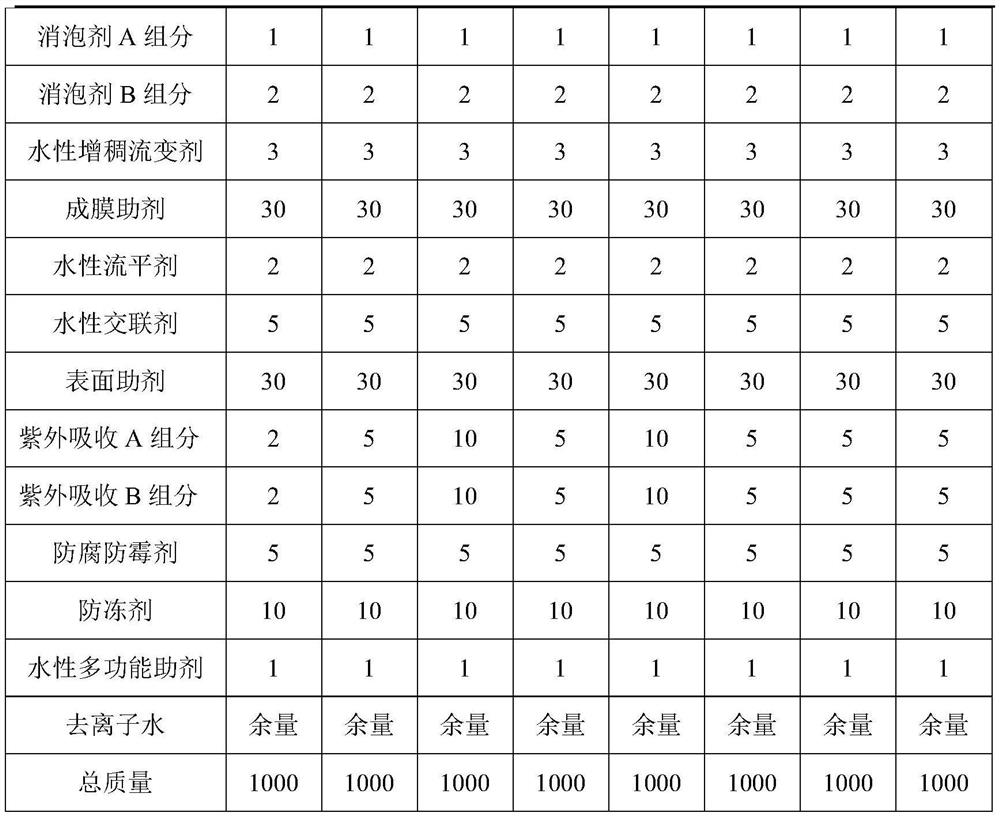

[0086] 1. Preparation of waterborne polyurethane outdoor wood paint

[0087] In the present embodiment, the adopted formula is shown in Table 3, and the raw material information involved in the formula is as follows:

[0088] The polyurethane dispersion A in the formula is the aliphatic waterborne polyurethane modified by mercapto-terminated modification prepared in the treatment 1 of Example 1.

[0089] Polyurethane dispersion B in the formula is the polyester type aliphatic aqueous polyurethane dispersion that the brand of Dongfang resin is 8201.

[0090] The water-based wetting agent in the formula is BYK-346 wetting agent.

[0091] The water-based defoamer in the formula includes defoamer A component and defoamer B component. The defoamer component A is Tego Chemical’s brand TEGO-810, and the defoamer component B is Corning The company's trademark is Dehydran 1293.

[0092] The water-based thickening rheology agent in the formula is the product of Mingling Company's bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com