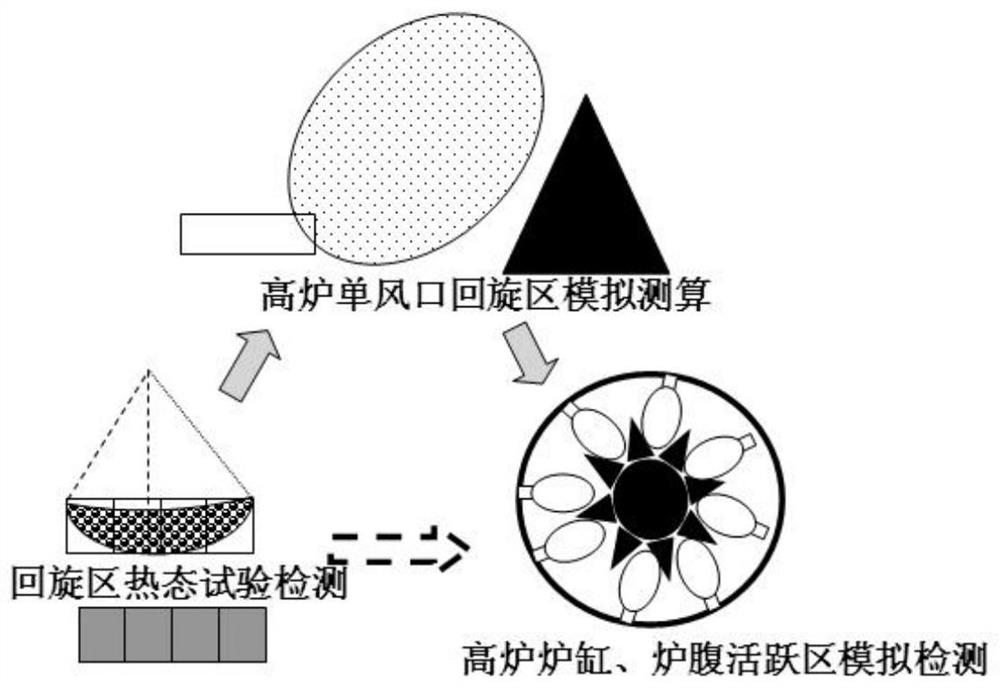

Blast furnace tuyere raceway test simulation technology and method

A simulation technology, the technology of the swirl area, which is applied in the field of iron and steel metallurgy, can solve the problems such as the technology of not detecting the size and shape of the tuyere swirl area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

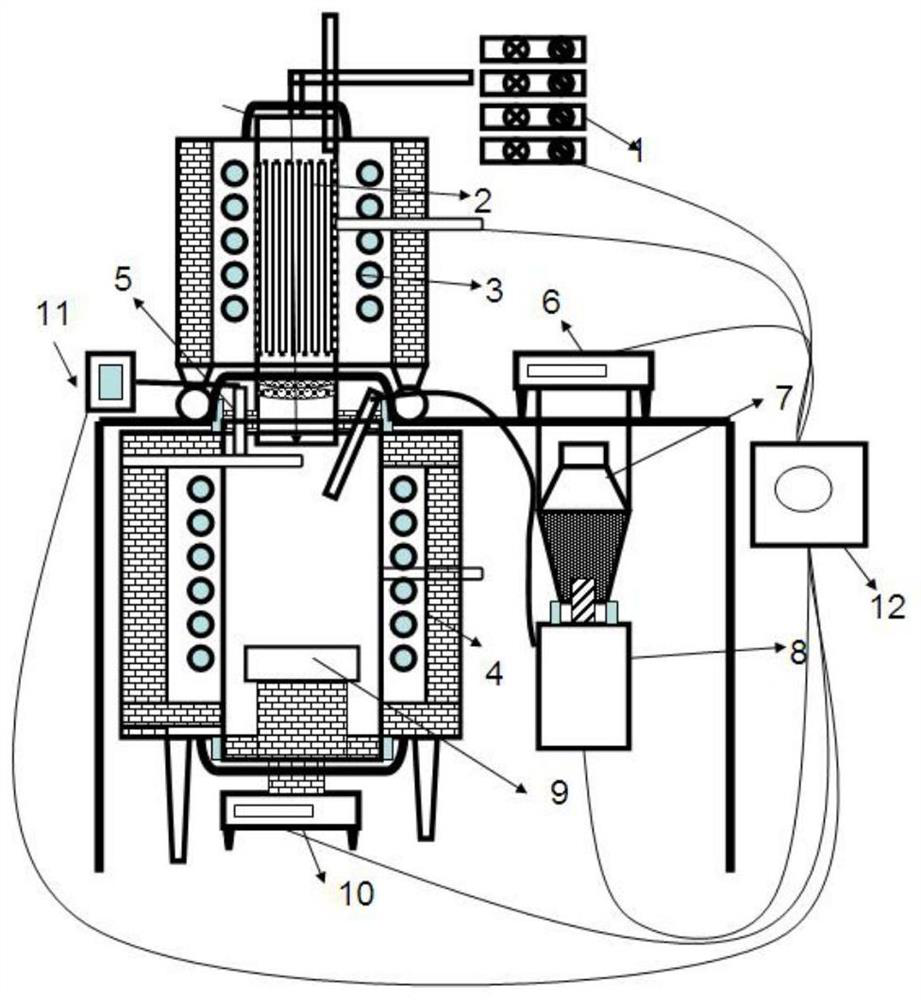

[0042] Description of equipment used:

[0043] Air is supplied by an air pump, oxygen and other gases (except steam) are supplied by cylinders, and steam is supplied by a small electric steam generator.

[0044] Flow meter and valve 1 are commonly used air, oxygen and other gas flow meters and control valves. Commonly used pipelines are quarter pipes or soft rubber pipes.

[0045] The porous ceramic tube 2 is designed to simulate the refractory checker bricks in the blast furnace hot blast stove. The outer diameter of the porous ceramic tube 2 is preferably 15 mm smaller than the inner diameter of the corundum tube inside the tube furnace. The length of the porous ceramic tube 2 is preferably 200 mm to 400 mm. Leave a distance of 50mm to 100mm between the inlet and outlet ends of the corundum tube.

[0046] The tube furnace 3 is mainly silicon-molybdenum rod tube furnace, and the tube furnace 3 has a diameter of 500mm-600mm and a length of 600mm-700mm. There are corundum tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com