EPR thermal shrinkage cable terminal internal defect detection system and detection method thereof

A heat-shrinkable cable, internal defect technology, used in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as harsh application conditions, discharge breakdown, and large environmental temperature effects, and achieve good promotion prospects and improve. The effect of signal-to-noise ratio and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

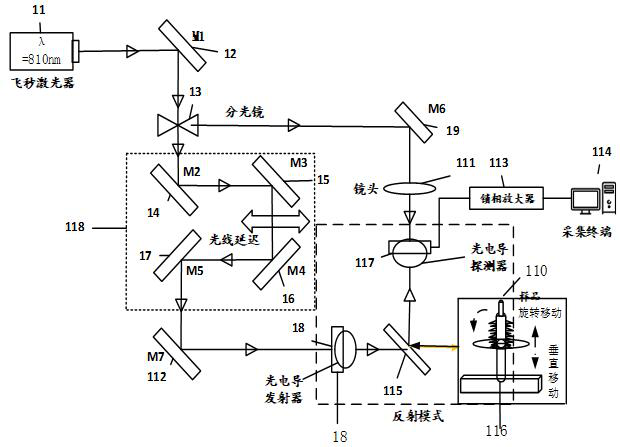

[0053] Such as Figure 1-2 As shown, an EPR heat-shrinkable cable terminal internal defect detection system includes: a femtosecond laser 11 and a beam splitter 13 arranged from left to right along the terahertz pulse path, a detection optical system and an excitation system arranged in parallel behind the beam splitter 13 The optical path system also includes a lock-in amplifier 113 and an acquisition terminal 114 connected to each other;

[0054] The detection optical path system includes a delay control unit 118, a photoconductive emitter 18, a reflector 8 115, and a two-degree-of-freedom fast-moving platform 116 arranged sequentially along the optical path from left to right; a photoconductive detector 117 is arranged above the reflector 8 115 The two-degree-of-freedom platform 116 is provided with the sample 110 of the EPR heat-shrinkable cable, and the sample 110 can move freely up and down on the vertical direction of the two-degree-of-freedom platform 116 and freely ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heart wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com