Compound solvent for removing carbonyl sulfide in gas and method for removing carbonyl sulfide

A technology for removing gas and carbonyl sulfide, applied in the field of gas purification, can solve the problems of low desulfurization efficiency, production of by-products, secondary pollution, etc., and achieve the effect of reducing loss and waste of resources, mild reaction conditions and full contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A compound solvent for removing carbonyl sulfide in gas, the compound solvent is mainly made of the following parts by weight of raw materials: 500-700 parts of physical absorbent, 200-350 parts of organic catalyst, 0.017- of metal complex 0.05 parts, 100-200 parts of water.

[0039]Further, the physical absorbent is polyethylene glycol dimethyl ether.

[0040]Further, the organic catalyst is N-methyldiethanolamine.

[0041]Further, the metal complex is binuclear sulfonated cobalt phthalocyanine.

[0042]Further, the saturated solubility of the binuclear sulfonated cobalt phthalocyanine in the compound solvent is 0.06 mg / mL.

[0043]Using organic catalysts and metal complexes instead of inorganic lye as carbonyl sulfide hydrolysis catalysts, using the physical absorption of organic catalysts and chemical adsorption of metal complexes, the synergistic effect of the dual catalysts has a good catalytic effect, which is beneficial to catalyze carbonyl groups. Hydrolytic conversion of sulfur.

[004...

Embodiment 2

[0059]A compound solvent for removing carbonyl sulfide from gas, mainly made of the following parts by weight of raw materials: polyethylene glycol dimethyl ether 600 parts, water 150 parts, dinuclear sulfonated cobalt phthalocyanine 0.033 parts, N-methyl 250 parts of diethanolamine;

[0060]The specific steps for removing carbonyl sulfide from the gas are as follows:

[0061](1) Preparation of compound solvent: Mix the above weight parts of polyethylene glycol dimethyl ether, dinuclear sulfonated cobalt phthalocyanine, N-methyldiethanolamine and water to obtain a compound for removing carbonyl sulfide from the gas With solvent

[0062](2) Take the above-mentioned compound solvent and place it in the absorption device. Under normal temperature and pressure conditions, the concentration of 308.28mg / Nm3The gas flow rate is 30mL / min, and the continuous reaction is 3h.

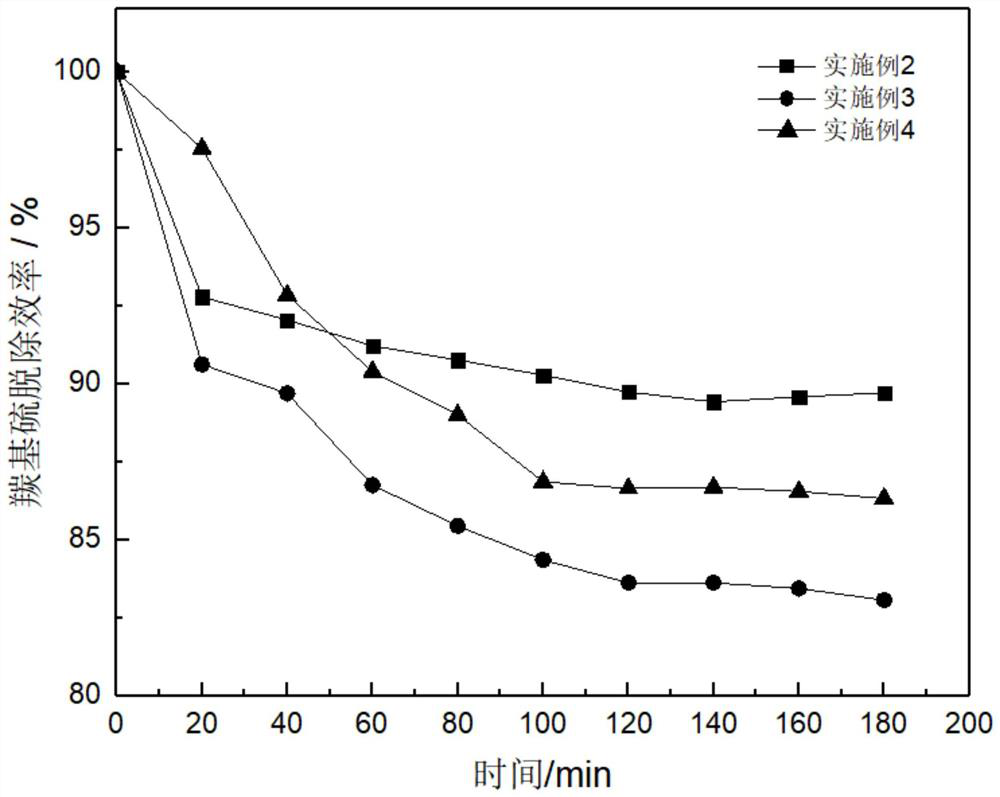

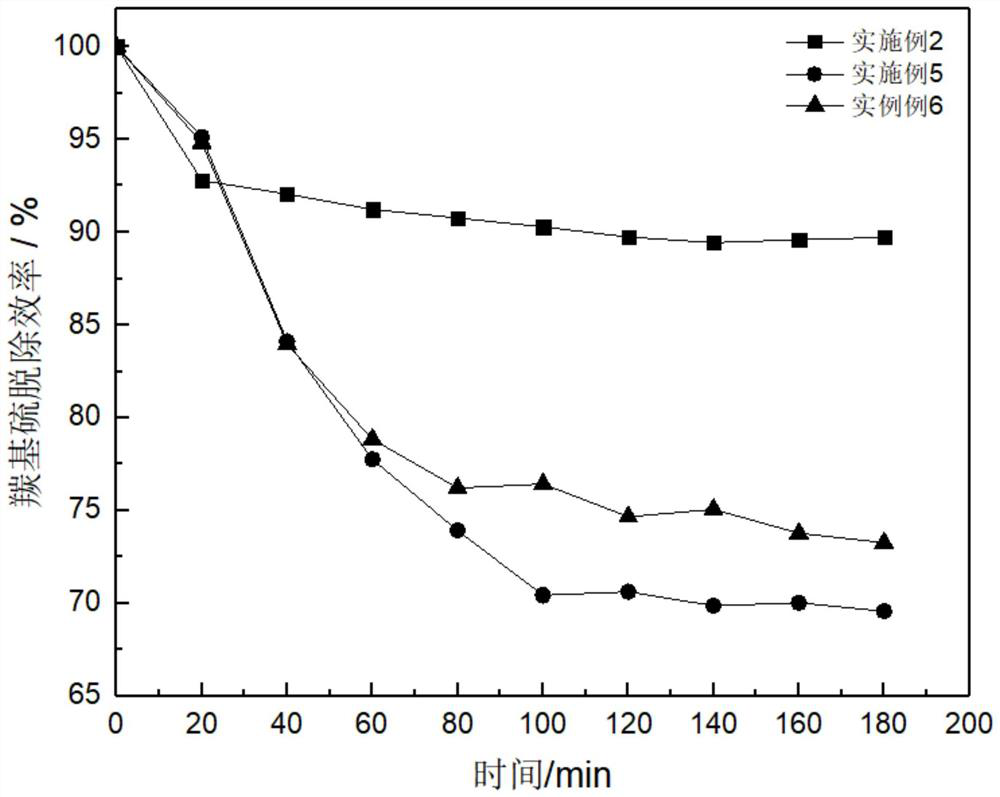

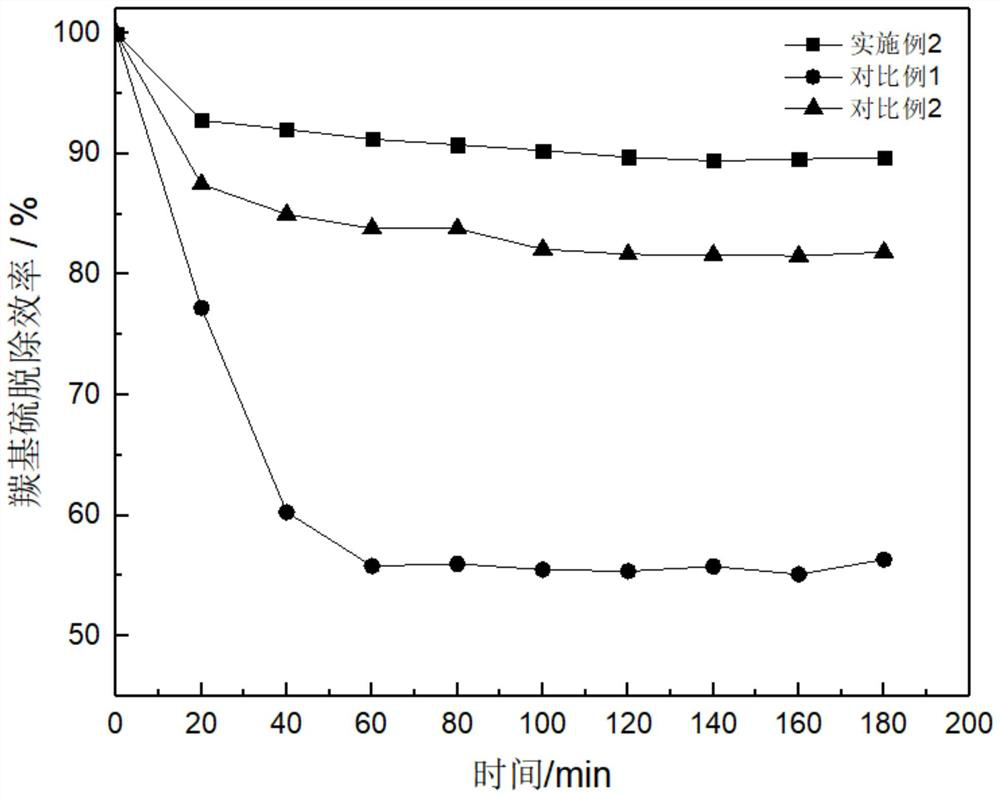

[0063]A sampler is used to take the desulfurized carbonyl sulfide gas at a sampling interval of 30 minutes. The carbonyl sulfide ...

Embodiment 3

[0066]A compound solvent for removing carbonyl sulfide in gas, mainly made of the following parts by weight of raw materials: polyethylene glycol dimethyl ether 600 parts, water 150 parts, dinuclear sulfonated cobalt phthalocyanine 0.017 parts, N-methyl 250 parts of diethanolamine;

[0067]The specific steps for removing carbonyl sulfide from the gas are as follows:

[0068](1) Preparation of compound solvent: Mix the above weight parts of polyethylene glycol dimethyl ether, dinuclear sulfonated cobalt phthalocyanine, N-methyldiethanolamine and water to obtain a compound for removing carbonyl sulfide from the gas With solvent

[0069](2) Take the above-mentioned compound solvent and place it in the absorption device. Under normal temperature and pressure conditions, the concentration of 308.28mg / Nm3The gas flow rate is 30mL / min, and the continuous reaction is 3h.

[0070]A sampler is used to take the desulfurized carbonyl sulfide gas at a sampling interval of 30 minutes. The carbonyl sulfide co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com