A kind of concrete hydration temperature rise inhibitor and preparation method thereof

A technology for concrete and inhibitor, applied in the field of concrete admixtures, can solve the problems of uncertainty of concrete performance, reduce the total amount of heat of hydration, inconvenient use, etc., achieve low product quality control requirements, large economic benefit potential, and reduce environmental The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

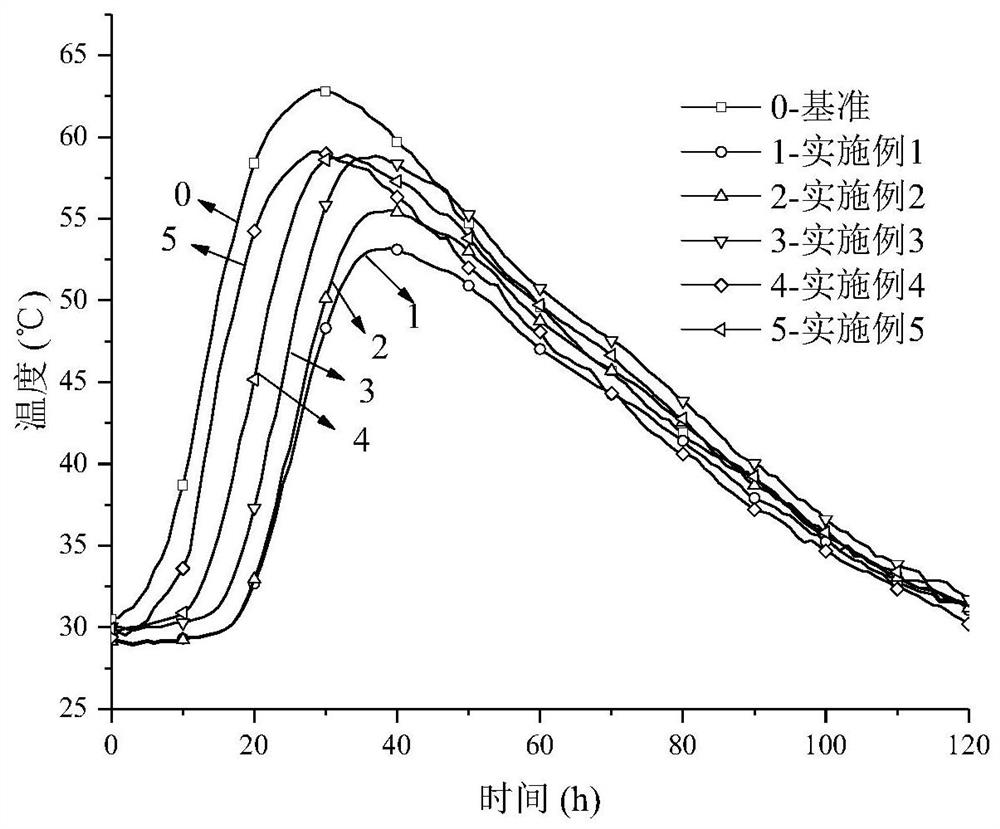

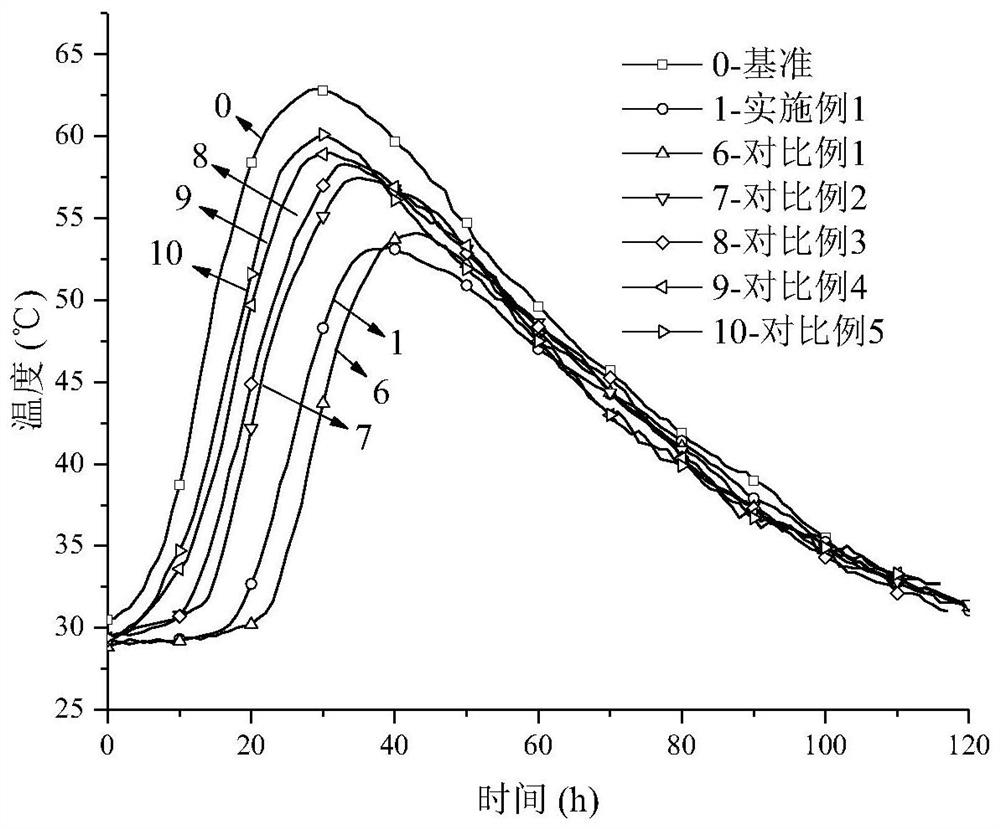

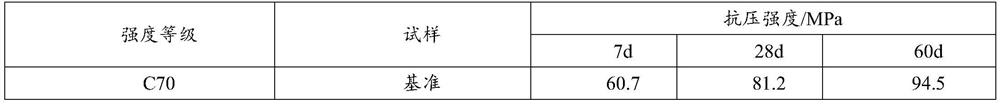

Examples

Embodiment 1

[0028] The preparation process of the present embodiment concrete hydration temperature rise inhibitor comprises:

[0029] Preparation of modified waste concrete hydration products: Mix 80 parts of 300-mesh waste concrete cement stone powder, 5 parts of nano-zinc oxide, 10 parts of sodium acetate, and 5 parts of hydroxyethylidene diphosphonic acid in a high-speed mixer at 800 r / min Stir for 3 hours, and finally dry it at 105°C for 40 minutes; wherein, the particle size of nano-zinc oxide is 80nm, sodium acetate is anhydrous sodium acetate, AR, 96%; hydroxyethylidene diphosphonic acid is a 60% aqueous solution .

[0030] Preparation of modified metakaolin: kaolin was calcined at 900°C for 2 hours, then poured into 5% pyrophosphoric acid solution at 23°C for water quenching to obtain water quenched slag of modified metakaolin.

[0031] Preparation of concrete hydration temperature rise inhibitor: pour 5 parts of modified waste concrete hydration products, 40 parts of modified m...

Embodiment 2

[0033] The preparation process of the present embodiment concrete hydration temperature rise inhibitor comprises:

[0034] Preparation of modified waste concrete hydration products: Mix 85 parts of 350-mesh waste concrete cement stone powder, 5 parts of nano-zinc oxide, 5 parts of sodium acetate, and 5 parts of hydroxyethylidene diphosphonic acid in a high-speed mixer at 700r / min Stir for 4 hours, and finally dry it at 105°C for 40 minutes; wherein, the particle size of nano-zinc oxide is 100nm, sodium acetate is anhydrous sodium acetate, AR, 96%; hydroxyethylidene diphosphonic acid is a 60% aqueous solution .

[0035] Preparation of modified metakaolin: calcining kaolin at 880°C for 3 hours, then pouring into 5% pyrophosphoric acid solution at 20°C for water quenching to obtain water quenched slag of modified metakaolin;

[0036] Preparation of concrete hydration temperature rise inhibitor: 5 parts of modified waste concrete hydration products, 45 parts of modified metakaoli...

Embodiment 3

[0038]The preparation process of the present embodiment concrete hydration temperature rise inhibitor comprises:

[0039] Preparation of modified waste concrete hydration products: Mix 90 parts of 400-mesh waste concrete cement powder, 2 parts of nano-zinc oxide, 5 parts of sodium acetate, and 3 parts of hydroxyethylidene diphosphonic acid in a high-speed mixer at 800r / min Stir for 3.5 hours, and finally dry at 105°C for 40 minutes; wherein, the particle size of nano-zinc oxide is 60nm, sodium acetate is anhydrous sodium acetate, AR, 96%; hydroxyethylidene diphosphonic acid is 60% aqueous solution.

[0040] Preparation of modified metakaolin: calcining kaolin at 900°C for 2.5 hours, then pouring into 5% pyrophosphoric acid solution at 23°C for water quenching to obtain water quenched slag of modified metakaolin;

[0041] Preparation of concrete hydration temperature rise inhibitor: pour 10 parts of modified waste concrete hydration products, 33 parts of modified metakaolin, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com