Flame-retardant silicone adhesive and preparation method thereof

A technology of silicone glue and flame retardant, applied in the field of silicone glue, can solve the problems of lack of flame retardancy, harm to human body and environment, and decline in mechanical properties, and achieve small inherent mechanical properties, affordable price, and good applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to a second aspect of the present invention, there is provided a method for preparing a flame-retardant silicone glue, comprising the steps of:

[0032] Heat and disperse α, ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil, flame retardant and inorganic filler under vacuum conditions, such as heating and dispersing under vacuum conditions in a double planetary mixer, and keep the vacuum degree -0.1 ~0.1MPa, temperature 100~110℃, high-speed dispersion stirring for 2~3 hours;

[0033] After lowering the temperature to room temperature, add crosslinking agent, coupling agent and catalyst, continue to disperse and stir for 20 to 30 minutes, and then discharge.

[0034] In a preferred embodiment of the present invention, when the added flame retardant is a composite flame retardant, the flame retardant is prepared by the following steps: aluminum hydroxide, magnesium hydroxide, aluminum hypophosphite, diethyl hypophosphite Several kinds of aluminum phosphat...

Embodiment 1

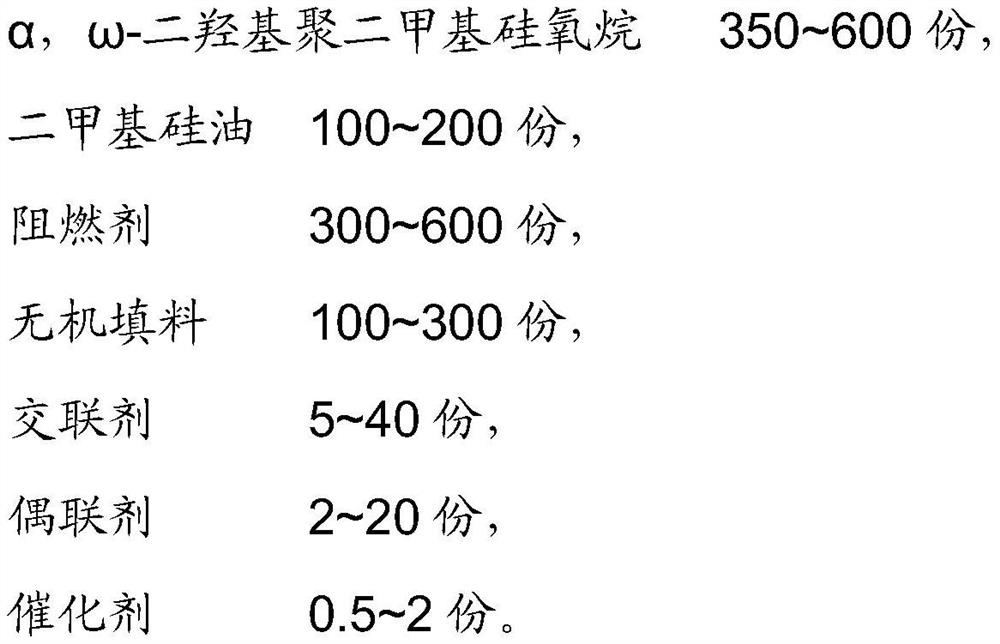

[0037] A kind of flame-retardant silicone glue, comprises the raw material of following mass parts:

[0038] 400 parts of α, ω-dihydroxy polydimethylsiloxane (2000 viscosity: 500000 viscosity = 5:1), 180 parts of dimethyl silicone oil (100 viscosity), 400 parts of flame retardant (aluminum hydroxide: hypophosphorous acid Aluminum: melamine cyanurate: zinc borate = 2:12:6:3), 200 parts of inorganic filler (heavy calcium carbonate: light calcium carbonate = 1:1), 20 parts of crosslinking agent (methyl triethyl Oxysilane), 10 parts of coupling agent (KH-550:KH-570=1:4), 1 part of catalyst (dibutyltin dilaurate).

[0039] The preparation method of above-mentioned flame retardant silicone glue, comprises the following steps:

[0040] (1) Add 400 parts of α, ω-dihydroxy polydimethylsiloxane, 180 parts of simethicone oil, 400 parts of fully mixed flame retardant, and 200 parts of inorganic filler into the double planetary mixer, turn on the vacuum and Heat and stir, keep the temper...

Embodiment 2

[0043] A kind of flame-retardant silicone glue, comprises the raw material of following mass parts:

[0044]α, ω-dihydroxy polydimethylsiloxane 400 parts (2000 viscosity: 50000 viscosity = 5: 1), 180 parts of dimethyl silicone oil (100 viscosity), 400 parts of flame retardant (aluminum hydroxide: hypophosphorous acid Aluminum: melamine cyanurate: zinc borate = 1:12:8:2), 250 parts of inorganic filler (light calcium carbonate), 25 parts of crosslinking agent (methyltriethoxysilane), 10 parts of coupling agent 1 part (KH-550: KH-570=1:4), 1 part of catalyst (dibutyltin dilaurate).

[0045] The preparation method of above-mentioned flame retardant silicone glue, comprises the following steps:

[0046] (1) Add 400 parts of α, ω-dihydroxy polydimethylsiloxane, 180 parts of dimethyl silicone oil, 400 parts of fully mixed flame retardant, and 250 parts of inorganic filler into the double planetary mixer, turn on the vacuum and Heat and stir, keep the temperature at 110° C., and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com