Nickel concentrate treatment process

A treatment process and concentrate technology, applied in the field of nickel concentrate treatment process, can solve the problems of high energy consumption, long reaction time and severe wear of power conveying equipment, achieve strong comprehensive utilization of resources, simple and reliable treatment process, The effect of easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

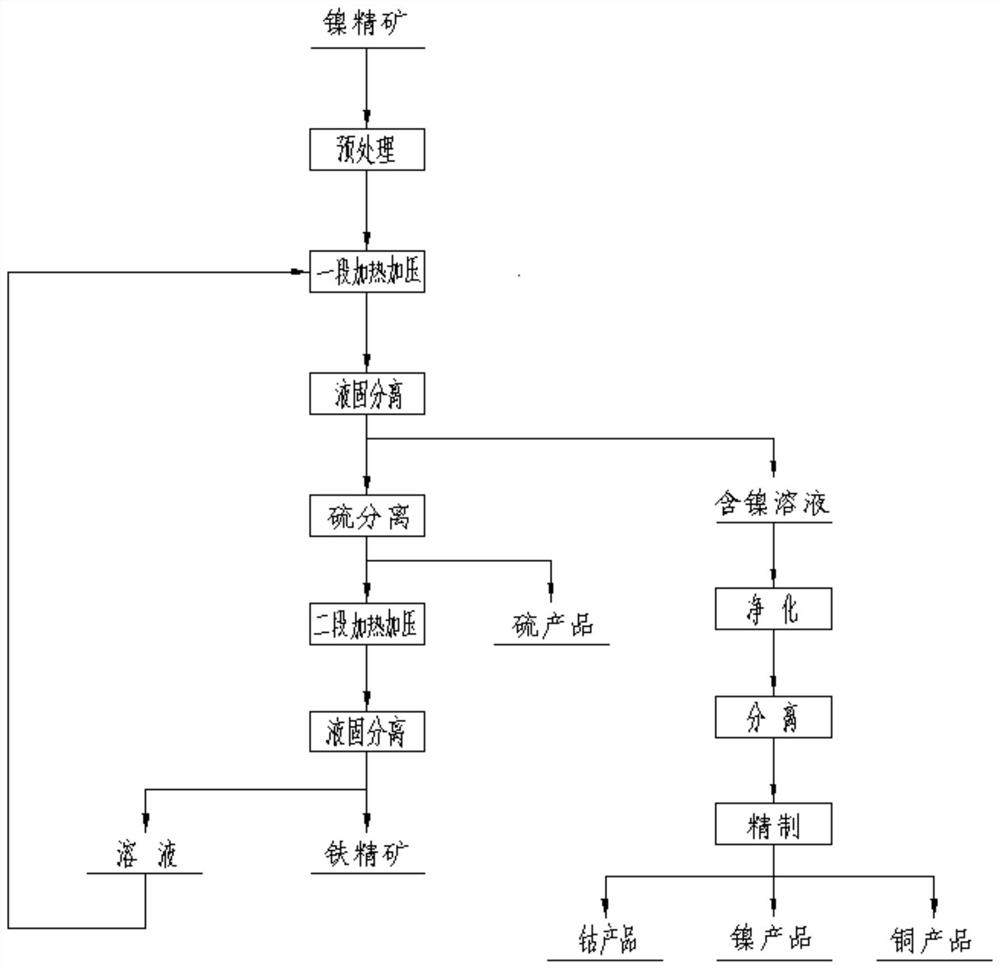

Image

Examples

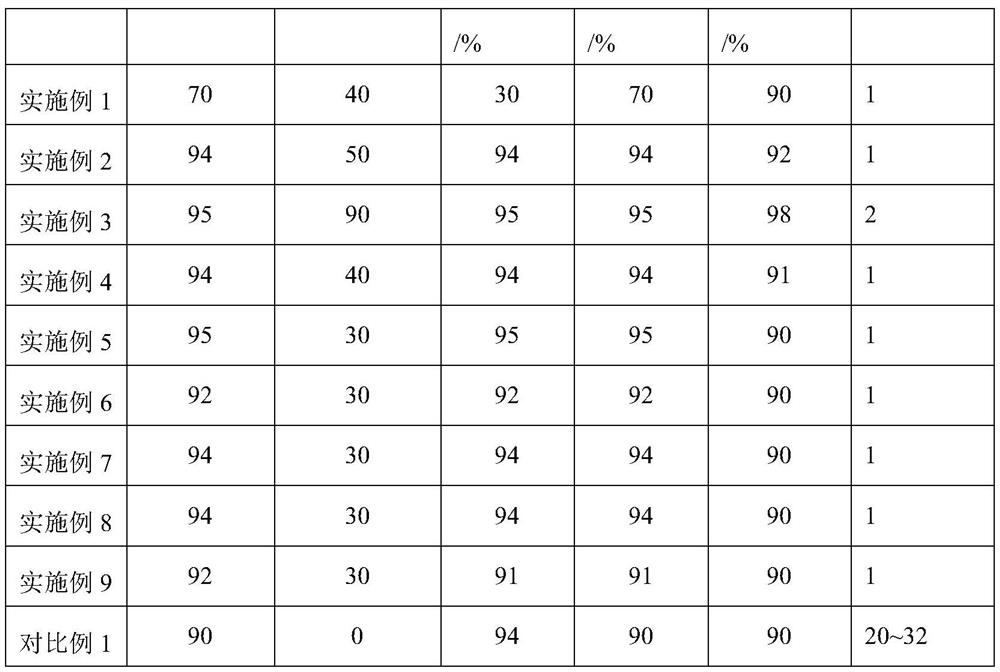

Embodiment 1

[0041] The nickel concentrate treated in this embodiment is a nickel sulfide ore with a nickel grade of 70%, which contains 4% copper, 2.5% iron, 2% zinc and 1.5% cobalt.

[0042] Grinding, washing and pulping are performed on the nickel concentrate, and the pH value of the pulp is adjusted to 4, and heated to 98°C.

[0043] The pulp after pH adjustment and heating is subjected to a stage of heating and pressure treatment, wherein the first leaching oxidant is pure oxygen, the reaction temperature is 115°C, the reaction pressure is 0.07MPa, and the reaction time is 5h. Then, the nickel-containing leaching solution and sulfur-containing leaching slag are obtained through sedimentation and separation.

[0044] Using flotation to separate the elemental sulfur in the leaching slag containing elemental sulfur to obtain the leaching slag for desulfurization;

[0045] Under the action of the compressed air of the second leaching oxidant, the desulfurization leaching slag is subjecte...

Embodiment 2

[0049] The same nickel concentrate as in Example 1 was used. The specific processing steps are as follows:

[0050] Grinding, washing and pulping are carried out on the nickel concentrate, and the pH value of the pulp is adjusted to 0.5, and heated to 50°C.

[0051] The pulp after pH adjustment and heating is subjected to a stage of heating and pressure treatment, wherein the first leaching oxidant is pure oxygen, the reaction temperature is 160°C, the reaction pressure is 1.0MPa, and the reaction time is 0.5h. Then, the nickel-containing leaching solution and sulfur-containing leaching slag are obtained through sedimentation and separation.

[0052] Using flotation to separate the elemental sulfur in the leaching slag containing elemental sulfur to obtain the leaching slag for desulfurization;

[0053] Under the action of the compressed air of the second leaching oxidant, the desulfurization leaching slag is subjected to two-stage heating and pressure treatment, wherein the...

Embodiment 3

[0057] The same nickel concentrate as in Example 1 was used. The specific processing steps are as follows:

[0058] Grinding, washing and pulping are performed on the above-mentioned nickel concentrate, and the pH value of the pulp is adjusted to 2.0, and heated to 90°C.

[0059] The pulp after pH adjustment and heating is subjected to a stage of heating and pressure treatment, wherein the first leaching oxidant is pure oxygen, the reaction temperature is 130°C, the reaction pressure is 0.6MPa, and the reaction time is 1.0h. Then, the nickel-containing leaching solution and sulfur-containing leaching slag are obtained through sedimentation and separation.

[0060] Using flotation to separate the elemental sulfur in the leaching slag containing elemental sulfur to obtain the leaching slag for desulfurization;

[0061] Under the action of the compressed air of the second leaching oxidant, the desulfurization leaching slag is subjected to two-stage heating and pressure treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com