Crystallization method of ferrous sulfate heptahydrate in sulfuric acid method titanium dioxide production process

A technology of ferrous sulfate and titanium dioxide, which is applied to ferric sulfate, separation methods, crystallization and separation, etc., can solve the problems of lengthy freeze crystallization and vacuum crystallization processes, high supersaturation of crystallization feed liquid, complex equipment, etc. Effect of exchange time, elimination of steam and power consumption, and prevention of scale deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

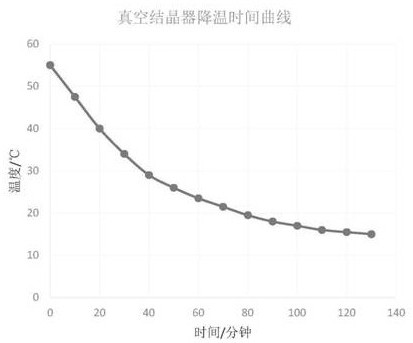

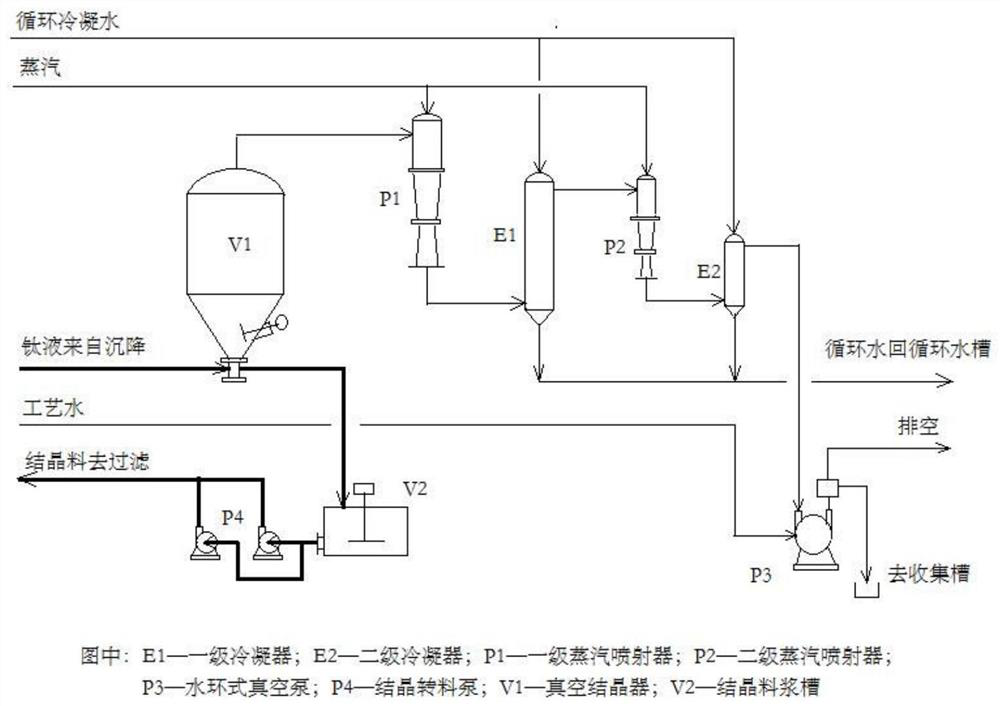

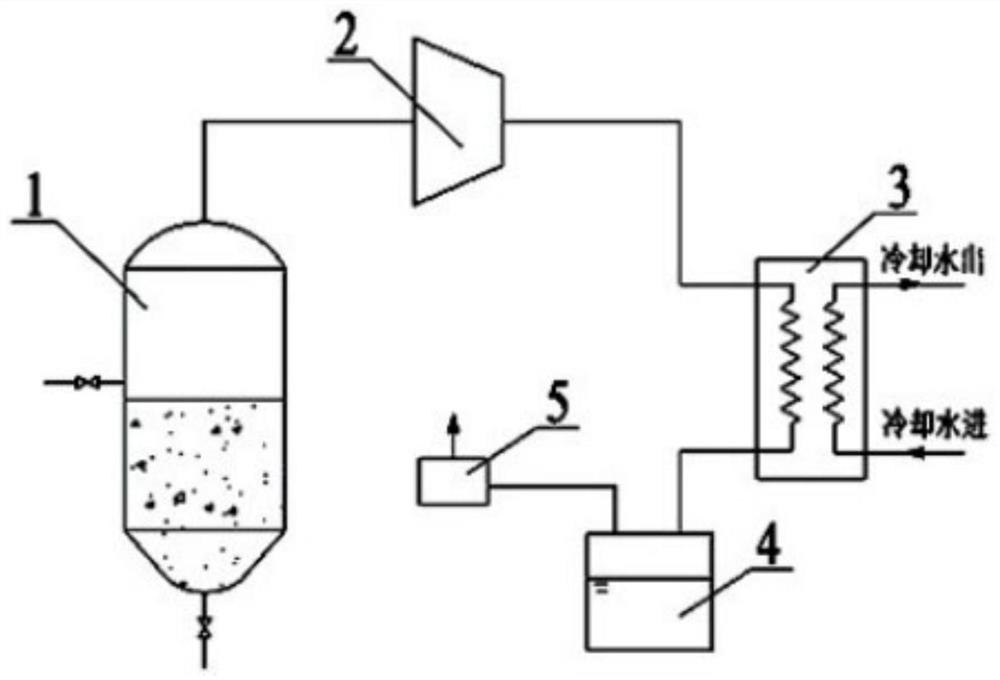

[0037] Such as Figure 4 As shown, the mixed titanium liquid from the production process of sulfuric acid titanium dioxide at a temperature of 55°C is continuously fed into a 30 cubic vacuum crystallizer. After adding about 20 cubic meters of the liquid, the vacuum crystallizer is turned on to stir, and the water ring vacuum pump is started. At the same time, start circulating cooling water until the volume of the feed liquid reaches 30 cubic meters. After the overflow of the vacuum crystallizer begins to overflow, stop feeding, and the equipment continues to operate until the temperature of the material in the vacuum crystallizer drops to 35°C and the absolute pressure is 10KPa. .

[0038] Then continuously add 60 cubic meters of material liquid per hour to the vacuum crystallizer, and continuously discharge 56.8 cubic meters per hour from the overflow port of the vacuum crystallizer. Bypass, directly overflow to the circulation crystallization, until the material in the cir...

Embodiment 2

[0044] Such as Figure 4 As shown, the mixed titanium liquid from the production process of sulfuric acid titanium dioxide at a temperature of 60°C is continuously fed into a 30 cubic vacuum crystallizer. After about 20 cubic meters of the liquid is added, the vacuum crystallizer is turned on to stir, and the water ring vacuum pump is started. At the same time, start circulating cooling water until the volume of the feed liquid reaches 30 cubic meters. After the overflow of the vacuum crystallizer begins to overflow, stop feeding, and the equipment continues to operate until the temperature of the material in the vacuum crystallizer drops to 40°C and the absolute pressure is 10KPa. .

[0045] Then continuously add 60 cubic meters of feed liquid per hour to the vacuum crystallizer, and continuously discharge 55.6 cubic meters per hour from the overflow port of the vacuum crystallizer. Bypass, directly overflow to the circulation crystallization, until the material in the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com