Recyclable sewage treatment system and process for mobile environment-friendly toilet

A sewage treatment system, mobile technology, applied in the direction of toilet black water treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of complex maintenance and management, large space occupation, death, etc., to reduce environmental pollution, Small footprint, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

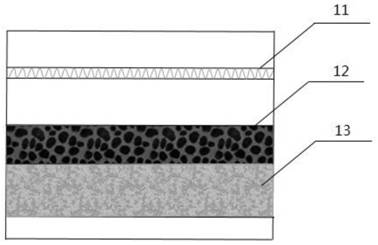

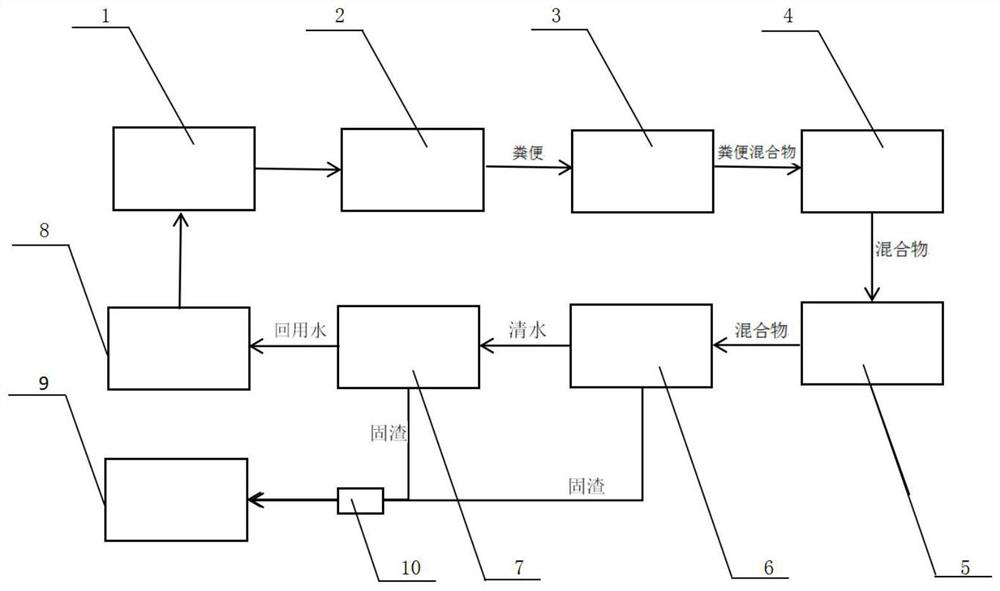

[0023] Such as figure 1 As shown, a recyclable sewage treatment system and process for a mobile environmental protection toilet is characterized in that: at least one end of the water storage tank 1 is connected to one end of the urinal 2, and one end of the urinal 2 is connected to the crushing device 3. One end is connected, one end of the crushing device 3 is connected to one end of the aerobic biofilm reactor 4, one end of the aerobic biofilm reactor 4 is connected to one end of the electrocoagulation treatment module 5, one end of the electrocoagulation treatment module 5 is connected to the sedimentation tank 6 One end of the sedimentation tank 6 is connected to one end of the multi-media filter 7, the bottom of the sedimentation tank 6 is connected to the bottom sludge port of the multi-media filter 7 through a pipeline and one end of the screw filter press 10 is connected, and the screw stack One end of the filter press 10 is connected to one end of the dung storage bo...

Embodiment 2

[0026] On the basis of embodiment 1, described aerobic biofilm reactor 4 technical process is as follows:

[0027] The sewage from the urinal 2 is fully mixed with the solid and liquid through the crushing device 3, and then enters the aerobic biofilm reactor 4 through the pipeline, so that the anaerobic bacteria in the sewage are converted into aerobic bacteria in the reactor and the activity of the aerobic bacteria and The sewage is fully mixed to promote the full degradation of organic matter in the water.

Embodiment 3

[0029] The process flow of the electrocoagulation treatment module 5 is as follows:

[0030] The sewage passes through the aerobic biofilm reactor 4 and enters the electrocoagulation treatment module 5 through the pipeline connection. The electrocatalysis of the three-dimensional electrode of the electrocoagulation treatment module 5 produces strong oxidizing substances, destroys the macromolecules in the sewage, and simultaneously combines with the Fe ions form colloidal precipitates, and cooperate with chemical treatment to produce sludge, so as to achieve the purpose of removing a large amount of suspended solids and organic matter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com