Oxychlorination reaction system and method based on four-stage reactor

An oxychlorination and reactor technology, which is applied in the field of oxychlorination reaction systems based on four-stage reactors, can solve the problems of easy release of catalysts into waste water, inability to meet low-load operation of factories, and low environmental pollution, etc. Achieve high selectivity, reduced dosage, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

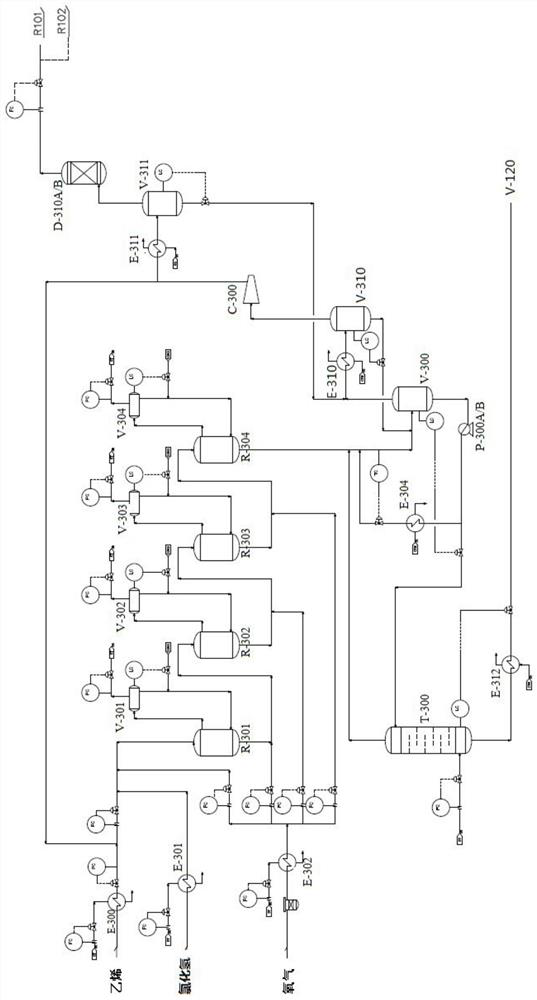

[0031] A kind of oxychlorination reaction unit based on four-stage reactor comprises four oxychlorination reactors connected in series in sequence, wherein:

[0032] Each oxychlorination reactor is a fixed-bed reactor, and each oxychlorination reactor is equipped with a cooling mechanism. The oxygen pipeline is connected to each oxychlorination reactor through an oxygen branch pipeline, and the hydrogen chloride pipeline is And the ethylene pipeline is connected with the primary oxychlorination reactor located at the head end.

[0033] As preferably, each oxychlorination reactor is a tubular fixed-bed reactor, and the oxygen pipeline, the hydrogen chloride pipeline and the ethylene pipeline are all equipped with a preheating mechanism, and the cooling mechanism is a high-pressure steam heat removal mechanism. Ethylene preheater E-300 is installed on the ethylene pipeline, HCL preheater E-301 is installed on the hydrogen chloride pipeline, and oxygen preheater E-302 is install...

Embodiment 2

[0036] A kind of oxychlorination reaction system based on four-stage reactor, comprises the oxychlorination reaction unit based on four-stage reactor as described in embodiment 1 and product aftertreatment and ethylene circulation unit, wherein: product aftertreatment and ethylene circulation The unit includes a gas-liquid separation tank for gas-liquid separation, the outlet of the four-stage oxychlorination reactor at the end communicates with the feed port of the gas-liquid separation tank, and the liquid outlet of the gas-liquid separation tank It is connected with the ethylene recovery tower through a pipeline to remove dissolved ethylene. There is packing in the ethylene recovery tower. The lower part of the ethylene recovery tower is provided with a steam inlet pipeline. The bottom of the ethylene recovery tower is connected to the EDC through a pipeline. Water wash tank V-120 is connected to collect dichloroethane.

[0037] Preferably, the gas-liquid separation tank is...

Embodiment 3

[0041] The oxychlorination reaction system based on the four-stage reactor is to convert ethylene (C 2 h 4 ), anhydrous hydrogen chloride (HCl) and oxygen (O 2 ) using copper chloride (CuCl 2 ) catalyst gas phase reaction to generate dichloroethane (EDC:C 2 h 4 Cl 2 ) and water (H 2 O). The reaction process is carried out in series in four tubular fixed-bed reactors. A large excess of ethylene is used to help control the reaction temperature and keep the oxygen concentration below the flammability limit. Unreacted ethylene is separated from the EDC and water, compressed and recycled back to the reactor system.

[0042] The overall reaction process on the catalyst bed;

[0043] C 2 h 4 (gas)+2HCl(gas)+1 / 2O 2 (air)→C 2 h 4 Cl 2 (liquid)+H 2 O (liquid)

[0044] Oxychlorination reaction method, comprises the following steps:

[0045] Step 1: Hydrogen chloride is preheated to about 155°C and transported to the first-stage oxychlorination reactor, ethylene preheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com