A kind of magnesium alloy superhydrophobic coating and its preparation method and application

A super-hydrophobic coating, magnesium alloy technology, applied in coatings, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable super-hydrophobic coatings, weakened super-hydrophobic properties, and excessive preparation time, and achieve excellent self- Cleaning effect, uniform distribution of rough structures, simple effect of chemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a kind of preparation method of magnesium alloy superhydrophobic coating, it comprises the following steps:

[0043] S1. Use metallographic sandpaper of 150#, 220#, 320#, 600#, 1000# and 2000# in sequence to polish the surface of the magnesium alloy with a size of 12mm×12mm×3mm, remove impurities, defects and Oxide, and then use 0.5W polishing paste to mechanically polish the magnesium alloy surface for 20 minutes through a metallographic polishing machine to form a glossy mirror surface, then use ethanol and deionized water to perform ultrasonic cleaning for 20 minutes, and dry it with pure nitrogen flow to obtain Polished magnesium alloy.

[0044] S2. Using a cross-shaped path, use a fiber laser to laser process the polished magnesium alloy, etch a grid structure, and then ultrasonically clean it with anhydrous ethanol for 20 minutes to obtain a laser-processed magnesium alloy; among them, the fiber laser The processing parameters are set as ...

Embodiment 2

[0047] This embodiment provides a kind of preparation method of magnesium alloy superhydrophobic coating, it comprises the following steps:

[0048] S1. Use metallographic sandpaper of 150#, 220#, 320#, 600#, 1000# and 2000# in sequence to polish the surface of the magnesium alloy with a size of 12mm×12mm×3mm, remove impurities, defects and Oxide, and then use 0.5W polishing paste to mechanically polish the magnesium alloy surface for 20 minutes through a metallographic polishing machine to form a glossy mirror surface, then use ethanol and deionized water to perform ultrasonic cleaning for 20 minutes, and dry it with pure nitrogen flow to obtain Polished magnesium alloy.

[0049]S2. Using a cross-shaped path, use a fiber laser to laser process the polished magnesium alloy, etch a grid structure, and then ultrasonically clean it with anhydrous ethanol for 20 minutes to obtain a laser-processed magnesium alloy; among them, the fiber laser The processing parameters are set as f...

Embodiment 3

[0052] This embodiment provides a kind of preparation method of magnesium alloy superhydrophobic coating, it comprises the following steps:

[0053] S1. Use metallographic sandpaper of 150#, 220#, 320#, 600#, 1000# and 2000# in sequence to polish the surface of the magnesium alloy with a size of 12mm×12mm×3mm, remove impurities, defects and Oxide, and then use 0.5W polishing paste to mechanically polish the magnesium alloy surface for 20 minutes through a metallographic polishing machine to form a glossy mirror surface, then use ethanol and deionized water to perform ultrasonic cleaning for 20 minutes, and dry it with pure nitrogen flow to obtain Polished magnesium alloy.

[0054] S2. Using a cross-shaped path, use a fiber laser to laser process the polished magnesium alloy, etch a grid structure, and then ultrasonically clean it with anhydrous ethanol for 20 minutes to obtain a laser-processed magnesium alloy; among them, the fiber laser The processing parameters are set as ...

PUM

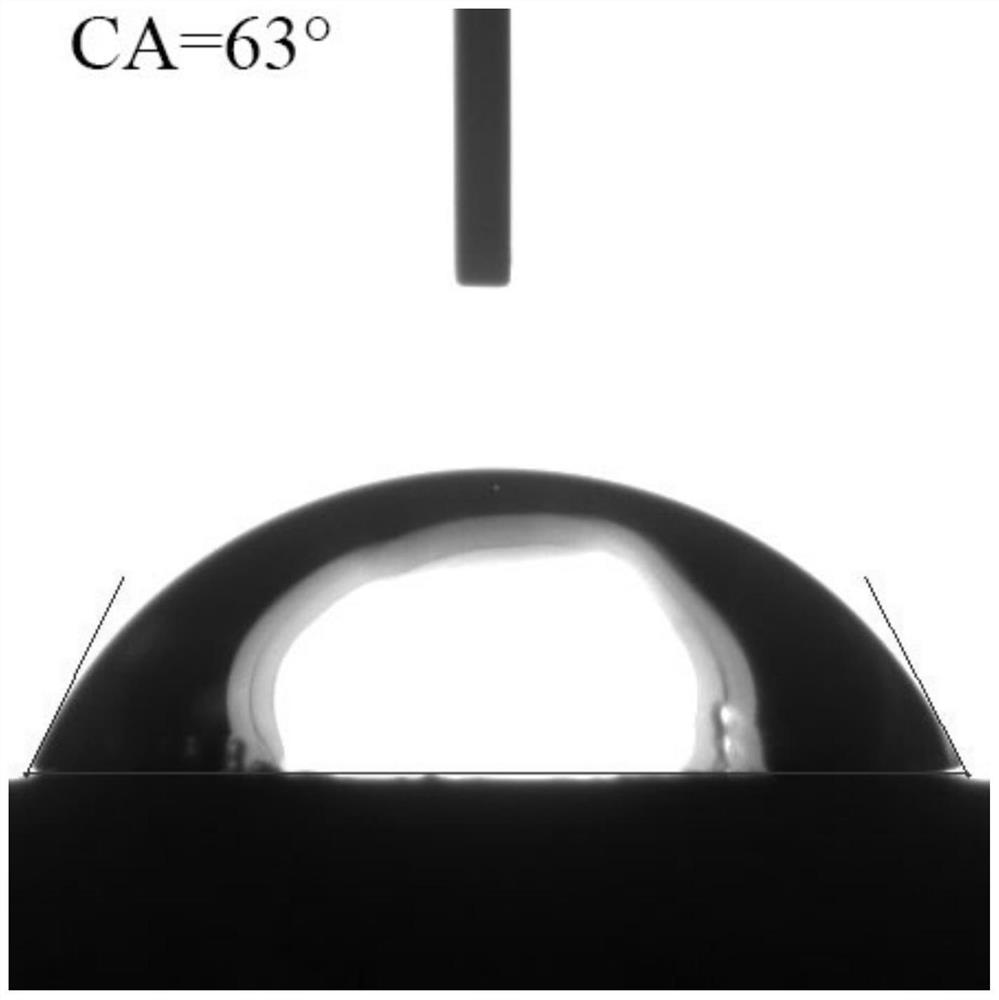

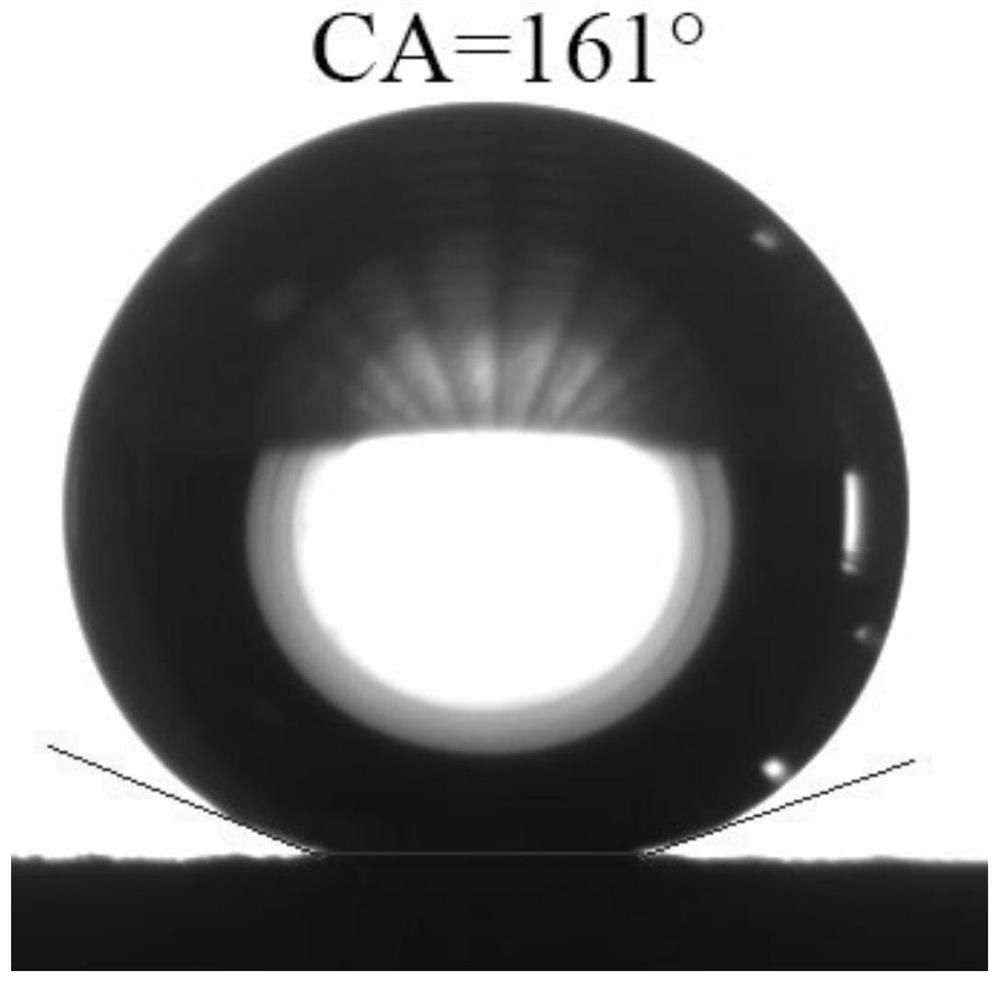

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com