Device and method for detecting sulfur isotopes in gas in continuous flow mode

A technology for sulfur isotope and gas detection, which is applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of environmental pollution, strong viscosity of pipelines, and difficult to store, and achieves convenient and fast operation and corrosion resistance. Strong performance and the effect of reducing retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

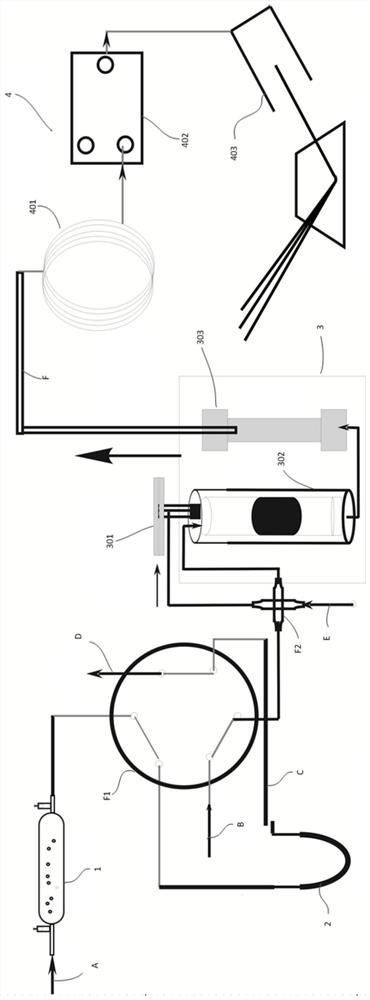

[0041] This embodiment provides a device for detecting sulfur isotopes in gas in continuous flow mode. See figure 1 , figure 1 A schematic diagram of the device for detecting sulfur isotopes in gas under continuous flow mode provided by the present invention is shown. Such as figure 1As shown, the device includes: a gas storage tank 1 for storing gas samples, a cold trap 2, an element analyzer 3, an isotope mass spectrometer 4, a six-way valve F1, a four-way valve F2, a first helium delivery pipeline A, a second Two helium delivery pipelines B, the first inlet pipeline C, the vent pipeline D, the oxygen delivery pipeline E, and the second inlet pipeline F; the element analyzer includes: a solid autosampler 301, a combustion furnace 302, and a reduction Furnace 303; the first helium delivery pipeline A, the gas storage tank 1, the cold trap 2, the first intake pipeline C, the combustion furnace 302, the reduction furnace 303, the second Two intake pipelines F and the isotop...

Embodiment 2

[0043] This embodiment provides a method for detecting sulfur isotopes in gas in continuous flow mode. This method is carried out in the device that embodiment 1 mentions, and described method comprises the following steps:

[0044] S1. Helium carries the gas sample released from the gas storage tank 1 through the first helium delivery line A into the cold trap 2 for cooling and adsorption, and the gas that is not cooled and adsorbed in the gas sample is discharged from the vent line D The device is ejected.

[0045] S2. Place the solid standard substance in the solid autosampler 301, enter the combustion furnace 302 through the solid autosampler 301, and simultaneously oxygen is transported to the combustion furnace through the oxygen delivery pipeline E In 302, the solid standard substance is fully burned to generate gas containing sulfur dioxide and sulfur trioxide, and then sent to the reduction furnace 303 to reduce the sulfur trioxide in the gas to sulfur dioxide.

[0...

Embodiment 3

[0051] Utilize the method that embodiment 2 provides to H in natural gas 2 The sulfur isotope of S was determined.

[0052] Adopt high-pressure aluminum alloy steel cylinders to collect natural gas, and natural gas is passed through the cold trap 2 of liquid nitrogen freezing (such as figure 1 shown), H in natural gas 2 S is frozen and enriched in cold trap 2, He, N 2 , and CH 4 After the gas not absorbed by freezing is emptied, the solid standard substance is sent into the element analyzer-isotope mass spectrometry system through the solid sampler 301, and the signals of m / e=36 and m / e=34 are measured.

[0053] Switching the six-way valve F1 to heat up the cold trap 2 will make the enriched H 2 Gases such as S are carried by He into the element analyzer-isotopic mass spectrometer, and the signals of m / e=36 and m / e=34 are measured; the signal of the sulfur isotope is compared with the signal of the sulfur isotope of the solid standard substance, according to the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com