Iron-manganese-containing layered transition metal oxide precursor material as well as preparation method and application thereof

A transition metal and oxide technology, applied in the field of nanomaterials and electrochemistry, can solve problems such as the limitation of complexing agents, and achieve the effect of easy amplification, market promotion, and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

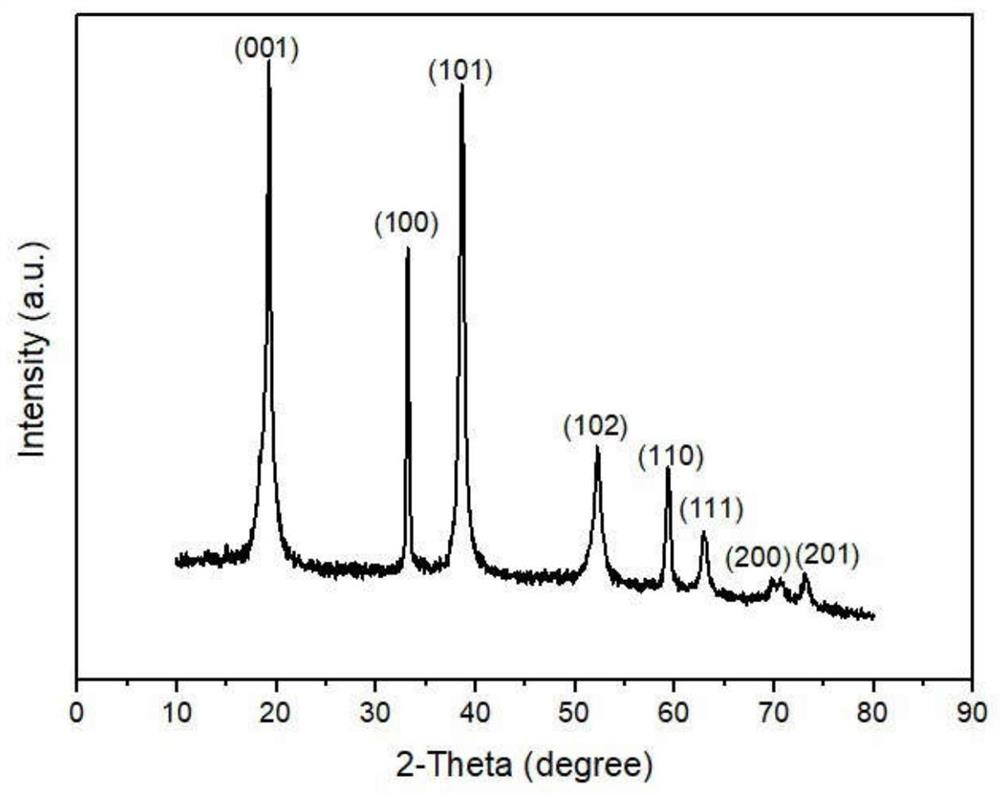

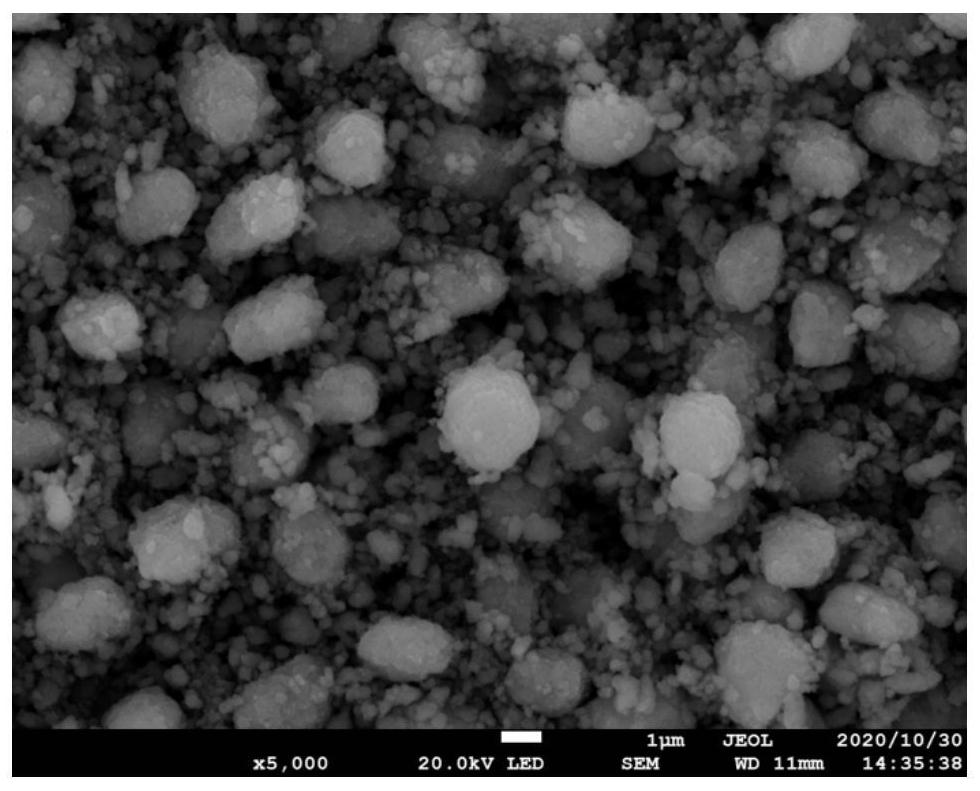

Image

Examples

Embodiment 1

[0033] 1) Add 1L of deionized water into the reactor, turn on the water bath switch, adjust the temperature of the reactor to 50°C, and adjust the pH of the liquid in the reactor to 10;

[0034] 2) Add 2mol / L nickel-iron-manganese mixed sulfate solution, 0.05M sodium pyrophosphate complexing agent solution and 4mol / L potassium hydroxide solution into the ternary coprecipitation reactor through a peristaltic pump, wherein the metal salt nickel The ratio of iron to manganese is 1:1:1, adjust the flow rate of the two solutions to maintain the pH value of the whole system at 10.2, maintain the reaction temperature at 50°C, pass nitrogen protection during the feeding process, and stir for 12 hours;

[0035]3) After 12 hours of reaction, stop feeding and continue stirring to age the slurry for 20 hours;

[0036] 4) Pour the aged slurry into a beaker and wash it repeatedly with deionized water until the slurry is neutral;

[0037] 5) Filter the slurry in step 4), and dry the filter ...

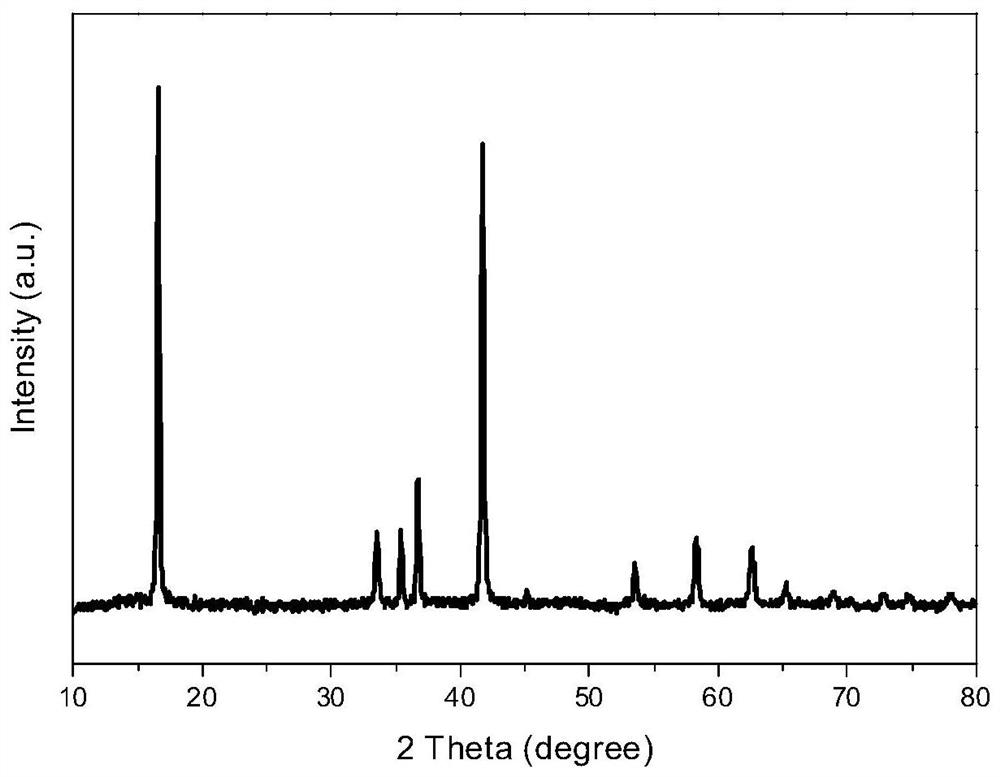

Embodiment 2

[0043] 1) Add 1L of deionized water into the reactor, turn on the water bath switch, adjust the temperature of the reactor to 50°C, and adjust the pH of the liquid in the reactor to 10;

[0044] 2) Add 2mol / L calcium-iron-manganese mixed sulfate solution and 0.1mol / L sodium pyrophosphate complexing agent solution into the ternary coprecipitation reactor through a peristaltic pump, wherein the ratio of the metal salt calcium-iron-manganese in the raw material is 1 :1:1, while feeding 4mol / L potassium hydroxide solution to maintain the pH value of the whole system at 10.2, maintaining the reaction temperature at 50°C, feeding nitrogen protection during the feeding process, and stirring for 12 hours;

[0045] 3) After 12 hours of reaction, stop feeding and continue stirring to age the slurry for 20 hours;

[0046] 4) Pour the aged slurry into a beaker and wash it repeatedly with deionized water until the slurry is neutral;

[0047] 5) Filter the slurry in step 4), and dry the fi...

Embodiment 3

[0051] 1) Add 1L of deionized water into the reactor, turn on the water bath switch, adjust the temperature of the reactor to 50°C, and adjust the pH of the liquid in the reactor to 10;

[0052] 2) Put 2mol / L zinc-iron-manganese mixed sulfate solution and 0.05mol / L sodium pyrophosphate complexing agent solution into the ternary coprecipitation reaction kettle through a peristaltic pump, wherein the ratio of metal salt zinc-iron-manganese in the raw material is 1 :1:1, while feeding 4mol / L potassium hydroxide solution to maintain the pH value of the whole system at 10.2, maintaining the reaction temperature at 50°C, feeding nitrogen protection during the feeding process, and stirring for 12 hours;

[0053] 3) After 12 hours of reaction, stop feeding and continue stirring to age the slurry for 20 hours;

[0054] 4) Pour the aged slurry into a beaker and wash it repeatedly with deionized water until the slurry is neutral;

[0055] 5) Filter the slurry in step 4), and dry the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com