A kind of mid-infrared detector and its preparation method

An infrared detector and solution technology, applied in semiconductor/solid-state device manufacturing, semiconductor device, final product manufacturing, etc., can solve problems such as staying in research and development, and achieve the goal of increasing viscosity, inhibiting nucleation speed, and improving uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

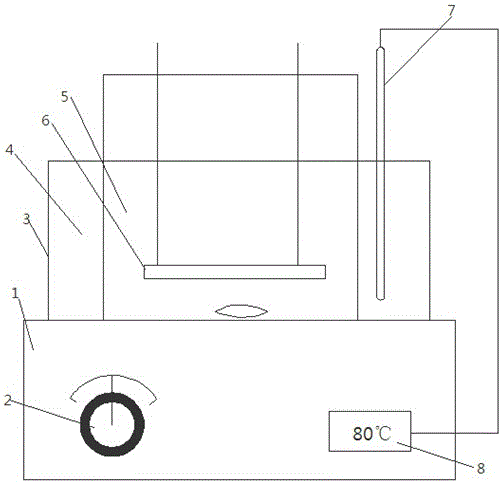

[0049] Preparation of lead salt thin film substrate: firstly, the deposition solution is moved into a deposition container, and the deposition container is placed in a water bath with a temperature of 50 to 100 ° C, and then the cleaned substrate is suspended in the middle of the deposition solution, and the rotation speed is 30 to 50 rpm The lead salt film substrate was obtained by stirring and depositing for 2.5 to 3 hours; for example: ① Turn on the magnetic stirrer, adjust and control the temperature of the water bath to 80 °C; ② Transfer the prepared solution 5 quantitatively to a 500 mL glass deposition container, wash the cleaned The quartz substrate is placed in the deposition solution horizontally; 3. the glass deposition vessel containing the solution 5 is sealed; the deposition vessel is placed in a water bath and heated and the rotational speed of the magnetic stirrer is adjusted to 50 rpm to start the deposition process; 4. Finish the deposition after 3h and take ou...

example 1

[0055] Choose a 30×40mm quartz substrate, clean it with standard cleaning process, dry it with high-purity nitrogen and place it on a fixed support.

[0056] 100mL of potassium hydroxide aqueous solution with mass concentration of 120g / L was added into the glass container filled with 190mL of distilled water, and 100mL of lead acetate solution with mass concentration of 180g / L was slowly added under the condition that the stirring speed was 300rpm. Add 10 mL of soluble starch solution with a mass concentration of 1 g / L and 100 mL of sodium selenosulfate solution with a mass concentration of 100 g / L in sequence at a dropping rate, and stir for 10 min to obtain 500 mL of colorless and transparent deposition solution.

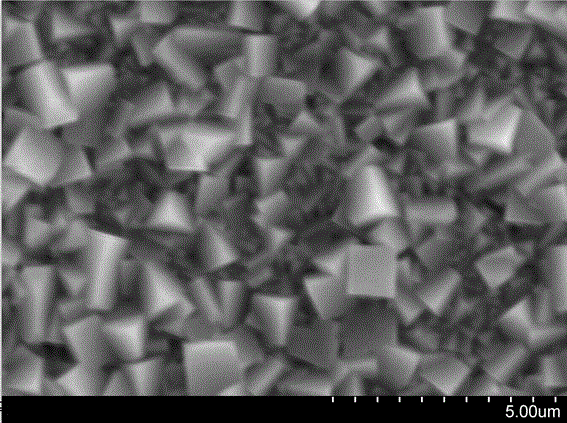

[0057] like figure 1 As shown, the fixed support with the substrate was horizontally suspended in the deposition solution, and transferred to a water bath at 75 °C and 40 rpm, sealed, and the substrate was taken out after 3 h to complete the deposition. The lead s...

example 2

[0064] Choose a 30×40mm ordinary glass substrate, clean it with standard cleaning process, dry it with high-purity nitrogen and place it on a fixed support.

[0065] Measure 100mL sodium selenosulfate solution with a mass concentration of 205g / L, 100mL lead acetate solution with a mass concentration of 180g / L, 100mL potassium hydroxide aqueous solution with a mass concentration of 160g / L, and 10mL soluble solution with a mass concentration of 1g / L The starch solution and 190 mL of distilled water were prepared in the same manner as in Example 1 to prepare 500 mL of deposition solution.

[0066] The fixed holder with the substrate was horizontally suspended in the deposition solution, transferred to a water bath at 80° C. and 45 rpm, sealed, and the substrate was taken out after 2.5 h to complete the deposition.

[0067] The attachments on the substrate were cleaned and cut into thin film substrates of 3mm×2mm.

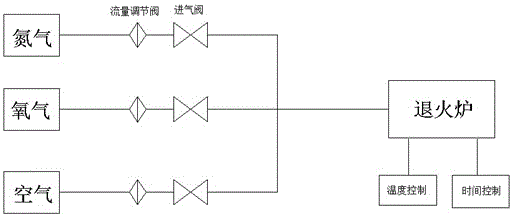

[0068] Put the thin film substrate into the annealing furnace, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com