Multistage multipoint water inlet enhanced denitrification sewage treatment system and method

A multi-point water inflow and denitrification technology, applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sewage treatment, etc., can solve problems such as increased treatment costs, inability to effectively reduce organic matter content, and lower effluent quality , to achieve the effect of saving treatment costs, avoiding the increase of effluent organic matter or total nitrogen, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

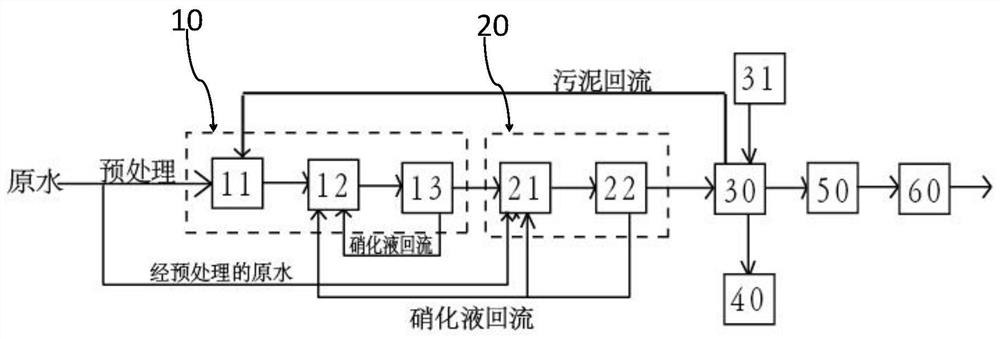

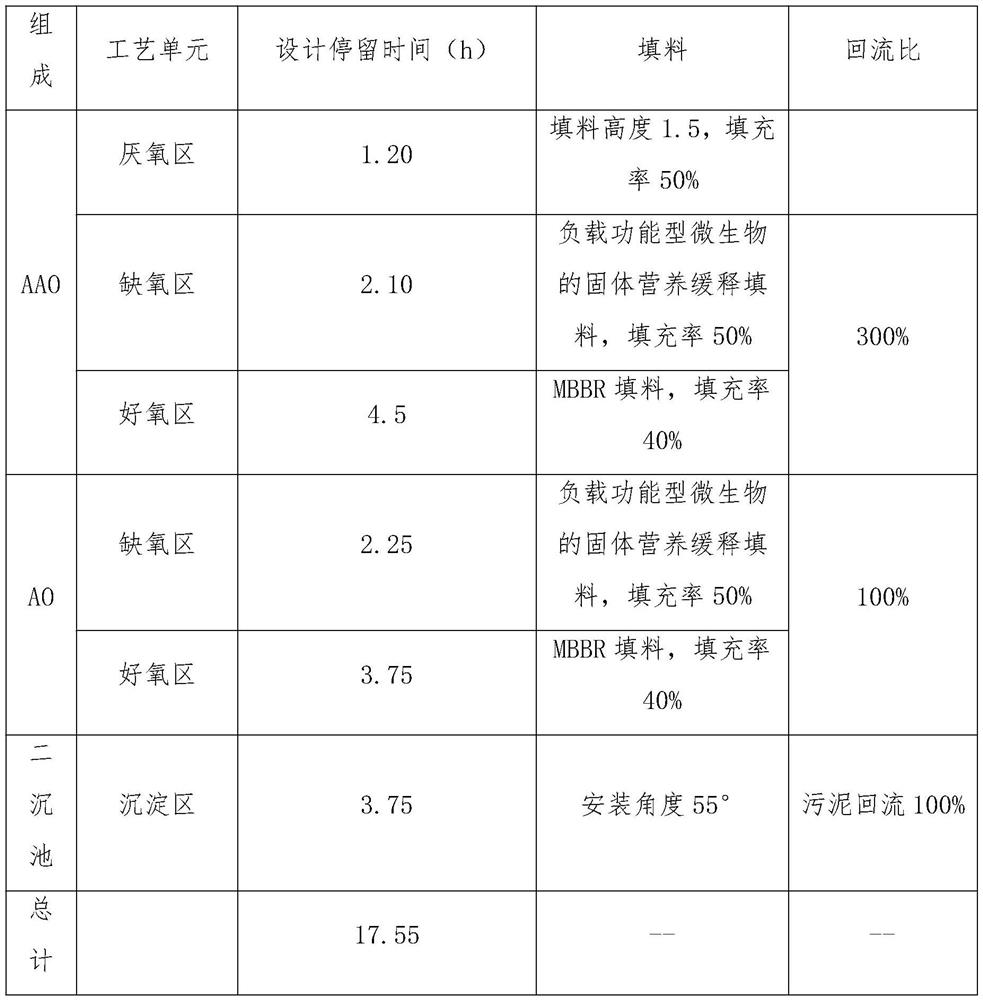

[0040] figure 1 As shown, it is a flow chart of a system for multi-stage and multi-point water inflow to strengthen denitrification treatment of sewage in a preferred embodiment of the present invention. The system includes an AAO biochemical treatment module 10 and an AO biochemical treatment module 20, wherein the AAO biochemical treatment module 10 is in front end, and the AO biochemical treatment module 20 is connected at the back end. The AAO biochemical treatment module 10 includes an anaerobic tank 11, a first anoxic tank 12 and a first aerobic tank 13 connected in sequence, and the AO biochemical treatment module 20 includes a second anoxic tank 21 and a second aerobic tank 22 connected in sequence .

[0041] The raw water is divided into at least two streams, which are treated by the grid and the regulating tank (adjusting the pH value to be close to neutral to adapt to microorganisms), wherein about 75-85% of the raw water of one stream enters the anaerobic pool of ...

Embodiment 2

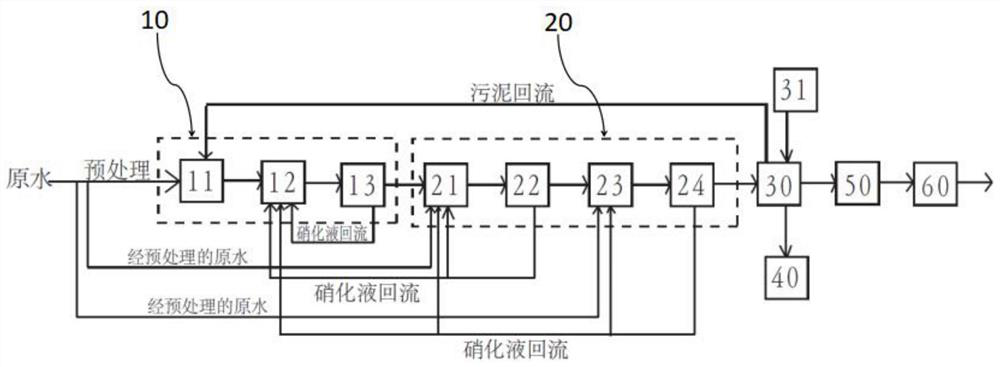

[0048] The difference between this embodiment and Embodiment 1 is that on the basis of Embodiment 1, the AO biochemical treatment module 20 further includes a third anoxic pool 23 and a third aerobic pool 24 connected in sequence. In the present embodiment, the raw water is divided into three stocks, wherein one (65%) enters the anaerobic tank 11 of the AAO biochemical treatment module 10 after pretreatment, and the effluent treated by the anaerobic bacteria of the activated sludge in the anaerobic tank 11 enters The first anoxic pond 12, the effluent treated by denitrifying bacteria in the first anoxic pond 12 enters the first aerobic pond 13; The effluent treated by the middle nitrifying bacteria enters the second anoxic pool 21 of the AO biochemical treatment module 20 together, and the effluent treated by the denitrifying bacteria in the second anoxic pool 21 enters the second aerobic pool 22 and is treated by the nitrifying bacteria; wherein, The first aerobic tank 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com