Oilfield produced water treatment process for removing oil by using oil-degrading flora

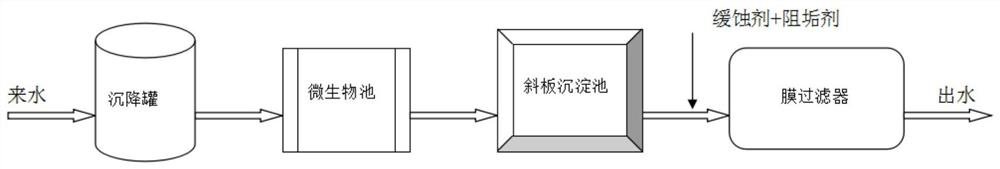

A treatment process and technology for produced water, applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of difficult sewage treatment, frequent backwashing, and expensive replacement of filter materials in oil production enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Taking the produced water of an oil field, using the crude oil produced as the only carbon source, the oil-loving bacteria group that spontaneously grew in the polluted soil was collected, and through multiple rounds of screening, purification and enrichment culture, the oil-degrading bacteria, that is, the oil-loving bacteria, were isolated. Bacillus licheniformis, Brevibacillus, and Pseudoxanthomonas were compounded into a biological agent at a ratio of 2:1:1, and put into the microbial pool for cultivation.

[0018] The oil content in the effluent water of the three-phase separator in an oil field is 100.5 mg / l, the median particle size is 8.6, the sulfur content is 6.4 mg / l, the iron content is 0.35, and the solid content is 128.7 mg / l.

[0019] Using this treatment process for treatment, it first enters the sedimentation tank, and the effluent enters the microbial tank. The sulfide is removed by the large-flow cyclone aerator at the front end of the microbial tank, ...

Embodiment 2

[0030] The same treatment process as in Example 1 was used to treat the produced water from another oilfield, and the process conditions were the same as in Example 1. The analysis results of the effluent water quality of each process section are shown in Table 5.

[0031] Table 5 Analysis results of effluent water quality in each process section

[0032] project Three-phase separator outlet Settling tank outlet Microbiological pool outlet Membrane outlet Solid mg / l 167.3 75.4 12.1 1.96 median particle size 5.1 4.1 3.5 1.12 Oil mg / l 88.5 56.2 0.0 0.0 Sulfur mg / l 3.4 3.2 0.1 0.0 Iron mg / l 0.2 0.2 0.1 0.0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com