Double-component adhesive and application in artificial board

An adhesive, two-component technology, applied in the direction of adhesives, layered products, adhesive types, etc., can solve the problems of reduced adhesive bonding performance, reduced formaldehyde release, high adhesive defect degree of adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

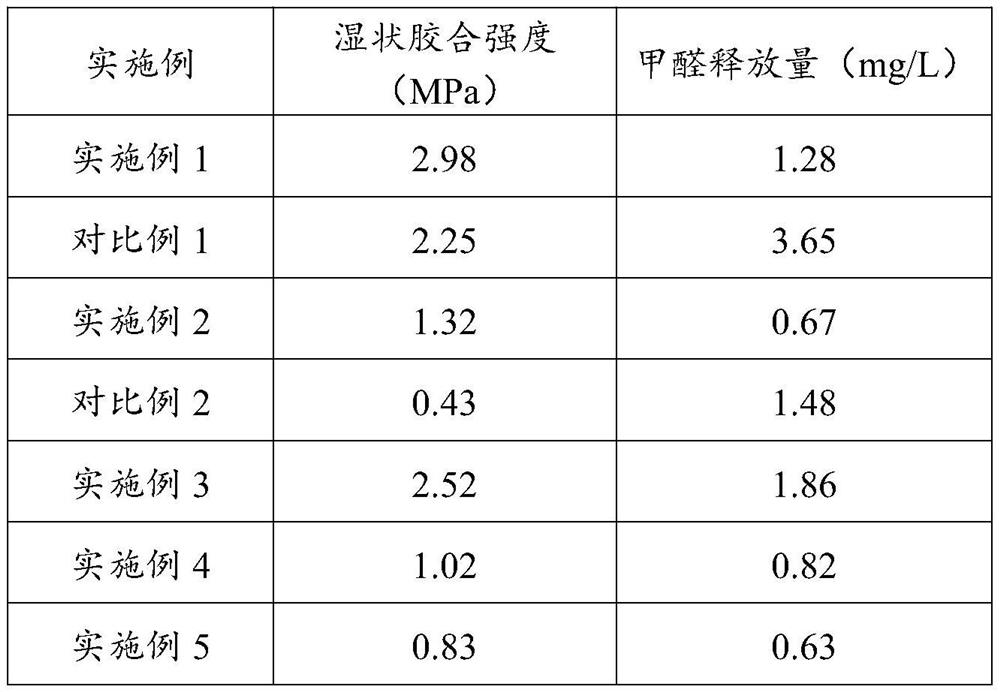

Examples

preparation example Construction

[0031] In the present invention, the preparation method of the two-component adhesive described in the above technical solution preferably includes the following steps:

[0032] Degrading after mixing the tannin and the degrading agent, mixing the obtained degraded tannin and the cross-linking agent to perform a cross-linking reaction to obtain component 2;

[0033] Mix components 1 and 2 before using the two-component adhesive to obtain a two-component adhesive.

[0034] In the present invention, the tannin is mixed with a degrading agent for degradation, and the obtained degraded tannin is mixed with a crosslinking agent for crosslinking reaction to obtain component 2. In the present invention, water is preferably added to the mixing of tannin and degradation agent. In the present invention, the mass ratio of the water and tannin is preferably (25-60):(15-60), more preferably (25-40):(16-20), in an embodiment of the present invention , the mass ratio of water to tannin is ...

Embodiment 1

[0059] Preparation of phenolic resin:

[0060] After heating up 95g (1.0mol) phenol to 80°C, mix it with a sodium hydroxide solution with a mass concentration of 10%, and adjust the pH of the phenol to 10.5; The heating rate was raised to 90°C, and the addition reaction was carried out for 60 minutes;

[0061] Cool the addition reaction product to 60°C and mix it with 0.3mol formaldehyde, raise the temperature to 90°C at a heating rate of 1°C / min, carry out polycondensation reaction for 30 minutes, then cool down to room temperature; dehydrate the product cooled to room temperature under negative pressure , to obtain a phenolic resin with a solid content of 60%.

[0062] To prepare a two-component adhesive:

[0063] The phenolic resin that 300g above-mentioned method is made is directly as component 1;

[0064] After mixing 100g of tannin, 186mL of water, 5g of sodium bisulfite and 3g of sodium sulfite, it was degraded at 120°C for 10h; the degraded product was cooled to ro...

Embodiment 2

[0071] Preparation of urea-formaldehyde resin:

[0072] 86g of formaldehyde solution with a mass concentration of 37% was heated up to 50°C and mixed with a 10% sodium hydroxide solution to adjust the pH value to 8.5, and the adjusted pH value of the formaldehyde solution was mixed with 30g of urea and 3g of melamine and then heated up Addition reaction at 90°C for 45 minutes; mix the product after the addition reaction with formic acid solution with a mass concentration of 10% to adjust the pH value to 4.8, and polycondense the solution with a pH value of 4.8 at 90°C for 30 minutes; Mix with 20g urea and carry out the second-step polycondensation reaction at 80°C for 30min, the product of the second-step polycondensation reaction is cooled to 30°C, and the pH of the second-step polycondensation reaction product is lowered by a sodium hydroxide solution with a mass concentration of 10%. The value was adjusted to 8.5 to obtain a urea-formaldehyde resin with a solid content of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com